Ring main unit plug temperature measuring system

A technology of ring network cabinet and plug, applied in the field of ring network cabinet, can solve the problems of increased workload, inconvenient maintenance and repair, and inconvenience of the background system, so as to reduce the background work tasks, avoid cluttered lines, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

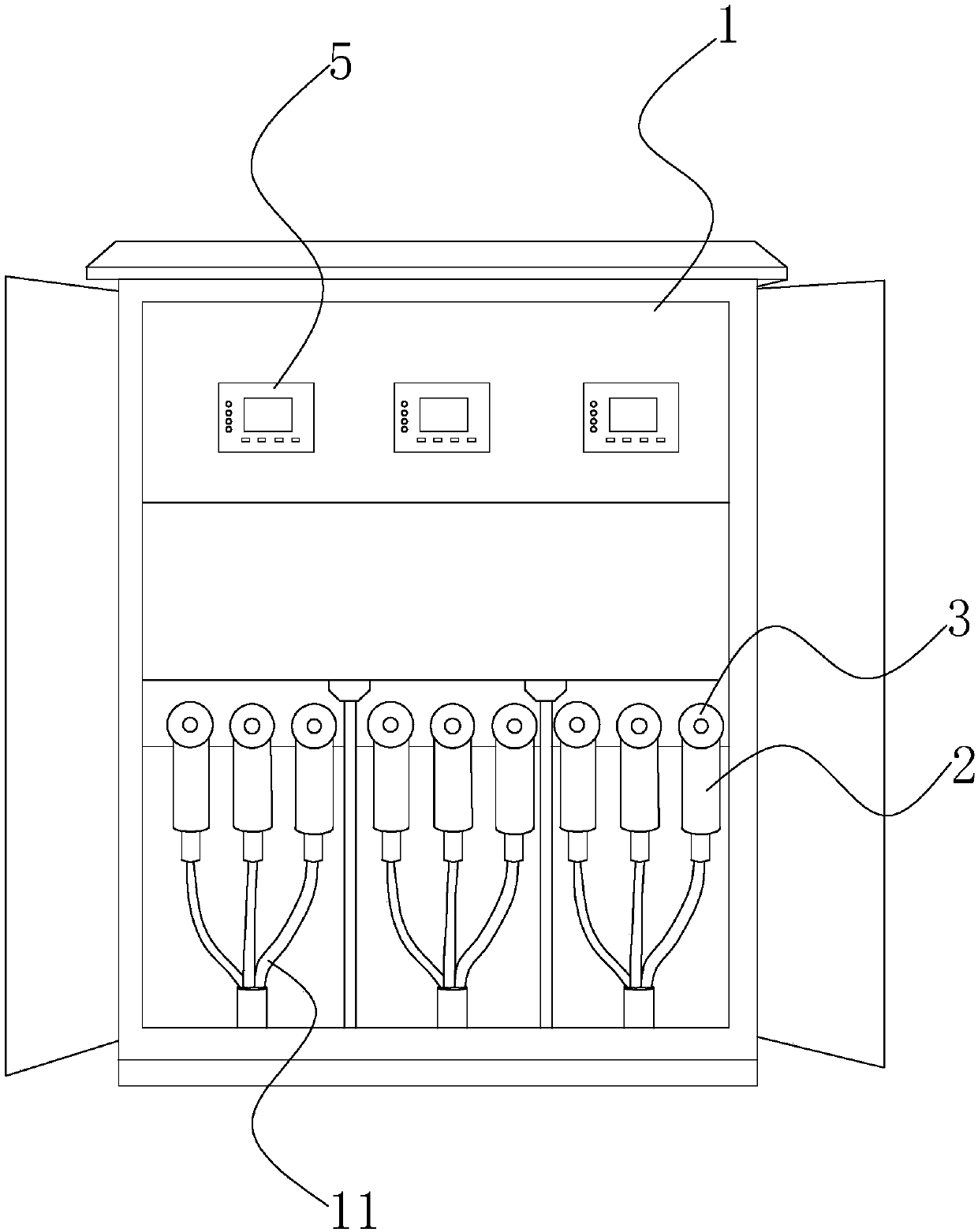

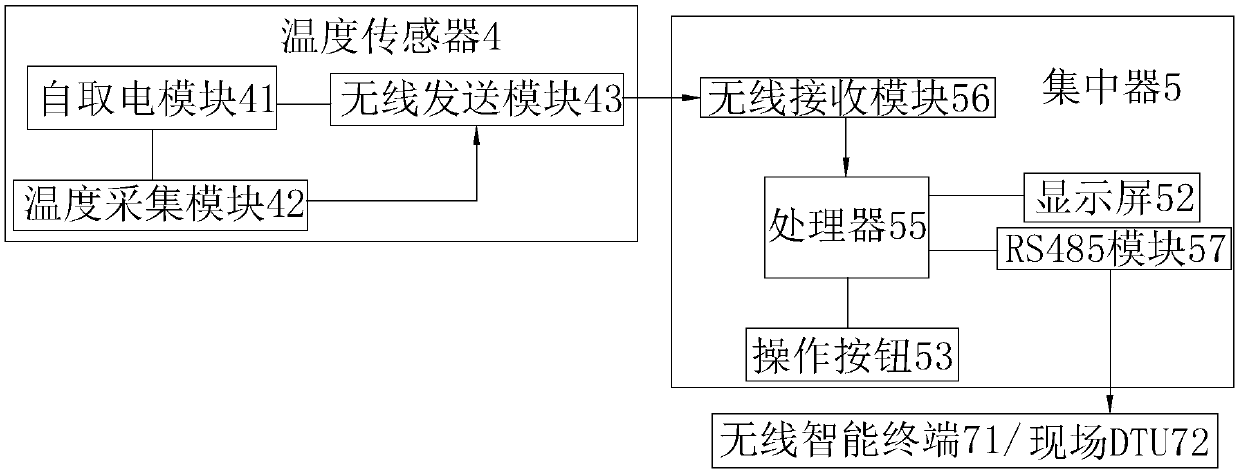

[0036] Such as figure 1 As shown, this embodiment discloses a ring main unit plug temperature measurement system, including a ring main unit 1, which has at least one set of three-phase lines 11 inside the ring main unit 1, and each phase line is connected to a T-shaped connection head 2. Preferably, the detection end 21 of the T-shaped connector 2 is inserted with an insulating plug 3, and the plug 3 is casted from black epoxy resin. There is a temperature sensor 4 inside the plug 3, and the temperature sensor 4 is used to detect the position of the T-shaped Three-phase wire temperature in the connector.

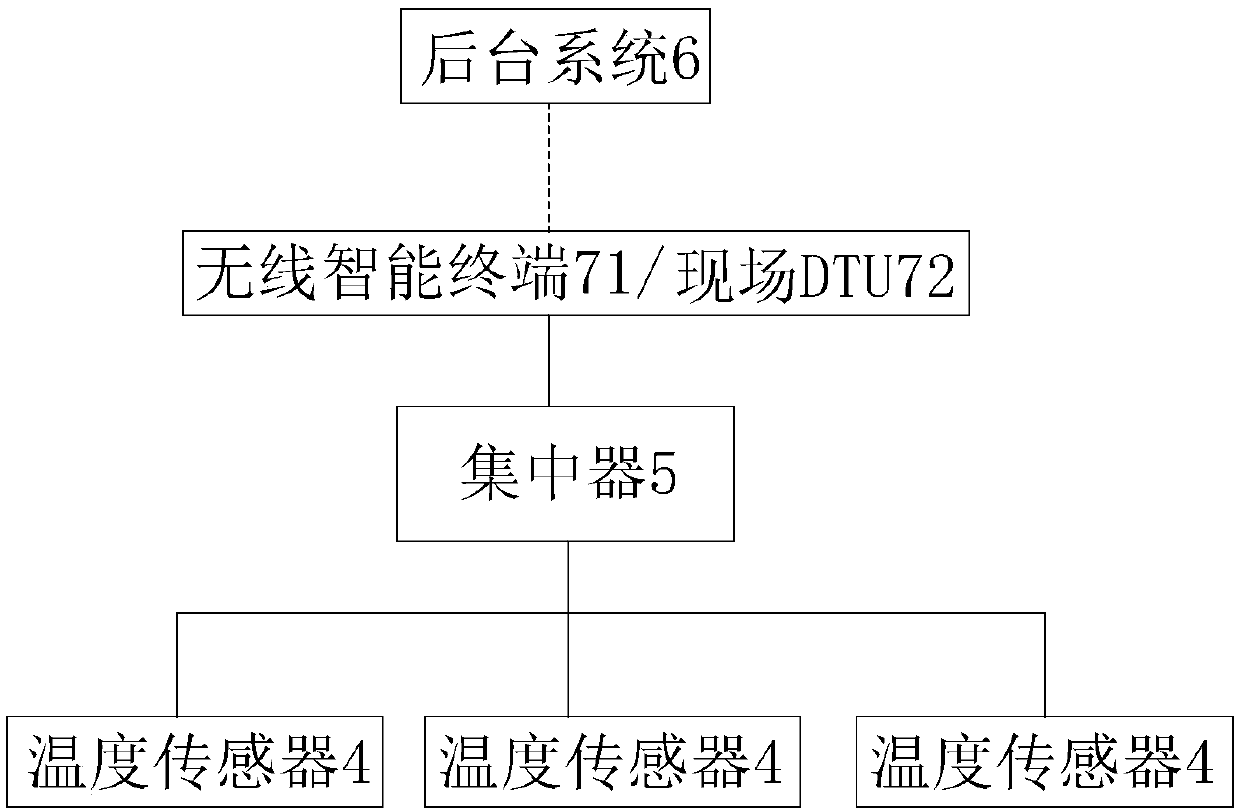

[0037] In particular, as figure 2 As shown, at least one concentrator 5 is embedded in the ring main unit 1, and multiple temperature sensors 4 are connected to the same concentrator 5, and the concentrator 5 is connected to the background system 6 through a wireless network. For example, there are three sets of three-phase lines 11 in the ring main unit 1, and each set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com