Liquid metal level probe and using method thereof

A liquid metal, liquid level probe technology, used in liquid level indicators, liquid/fluid solids measurement, engine lubrication, etc., can solve the problem that liquid level sensors are not suitable for liquid metal systems and cannot solve the high corrosiveness of liquid sodium , Unable to meet the requirements of high temperature and high sealing, and achieve the effects of reliable measurement results, simple and effective design, and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

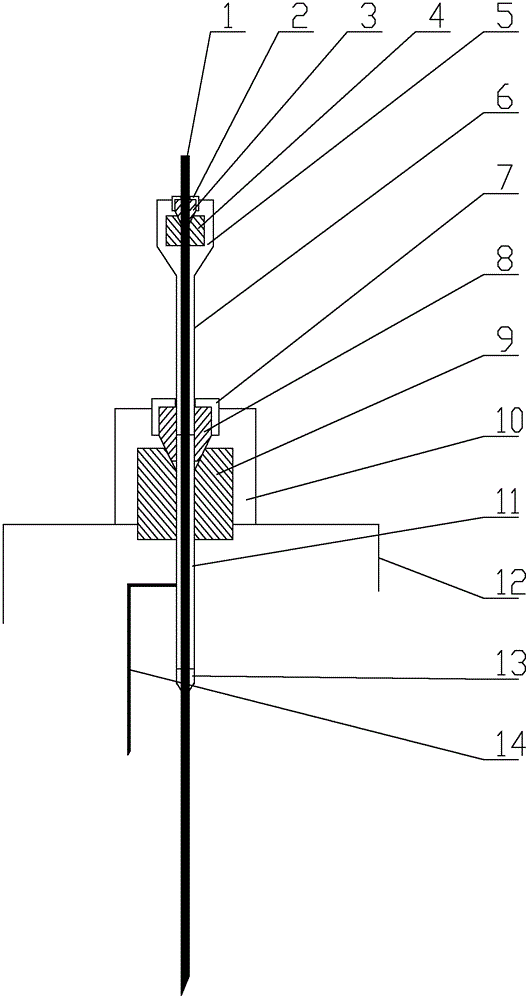

[0026] see figure 1 , the middle of the device is a long low-level probe 1, and the upper compression nut (external thread) 2 is set 10cm away from the upper end of the low-liquid level probe 1, and the lower side of the upper compression nut 2 is installed with polytetrafluoroethylene. Vinyl block A, the upper compression nut 2 cooperates with the upper boss (internal thread) 5, the upper boss 5 is installed with a polytetrafluoroethylene block B, the lower side of the upper boss 5 is welded with a stainless steel sleeve 6, and the stainless steel sleeve 6 The middle part is covered with a lower compression nut (external thread) 7, and a polytetrafluoroethylene block C is installed on the lower side of the lower compression nut 7, and the lower compression nut 7 cooperates with the lower boss (internal thread) 10, and the lower boss The polytetrafluoroethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com