Chip

A chip and main body technology, applied in the field of nucleic acid detection, can solve problems such as deterioration detection ability, decline, aerosol pollution, etc., and achieve the effect of convenient operation and improved operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

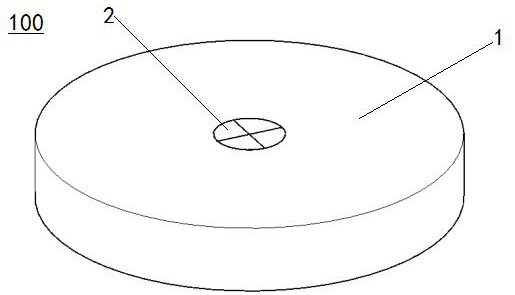

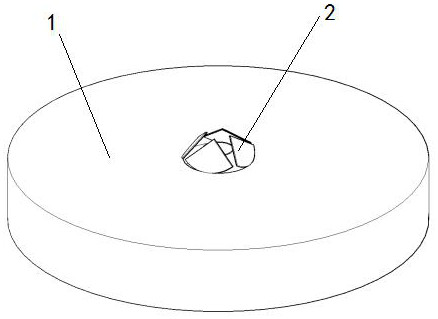

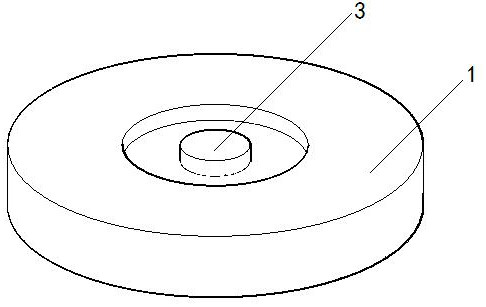

[0049] like Figure 1-Figure 11 As shown, this embodiment provides a chip 100, which is mainly used for nucleic acid detection, and includes a main body 1, a top cover 2 and a storage member 3. A through hole 17 is opened in the middle of the main body 1, and the upper end of the through hole 17 is connected to the top cover. 2 is connected by an openable sealing layer and closed by the top cover 2, a plurality of flow channels 5 are opened on the outer periphery of the through hole 17, one end of each flow channel 5 is connected to the through hole 17, and the other end of each flow channel 5 is connected to a The reaction chamber 6, the reaction chamber 6 is not communicated with the outside world, and at the same time, it cooperates with the setting of the top cover 2 to form a good sealing condition, which can prevent the detection reagent from contacting the outside for a long time before the reaction starts, and prevent the detection reagent from being oxidized, damp or p...

Embodiment 2

[0055] like Figure 12 As shown, the difference between this embodiment and the first embodiment is that the outer wall of the base 11 is provided with a ring of accommodating grooves, and the accommodating groove is used to embed the bottom sealing ring 12, and the outer diameter of the bottom sealing ring 12 is equal to the outer diameter of the base 11, In addition, the outer wall of the bottom sealing ring 12 is in contact with the inner wall of the through hole 17, so that the sealing effect can be improved through the bottom sealing ring 12, and the detection reagent in the storage part 3 can be prevented from deteriorating due to moisture and oxidation. The bottom sealing ring 12 can be made of rubber material. .

Embodiment 3

[0057] like Figures 13-14 As shown, the difference between this embodiment and the second embodiment is that a limit groove 18 is provided on one side of the groove 4, a limit rod 19 is fixed on the outer edge of the base 11, and the lower bottom surface of the limit rod 19 and the bottom surface of the base 11 are fixed. On the same horizontal plane, the end of the limit rod 19 away from the base 11 can extend into the limit groove 18, and the width of the limit rod 19 is equal to the width of the limit groove 18, and the limit rod 19 is positioned at the upper limit in the horizontal direction to ensure that the limit rod 19 can only reciprocate in the vertical direction, thereby preventing the rotation of the storage member 3 relative to the through hole 17, affecting the alignment of the flow channel 5 and the liquid inlet hole 7, and the position of the limit groove 18. The depth is equal to the sum of the height of the limit rod 19 and the depth of the groove 4 . When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com