Ultrasonic flaw detector

A flaw detector and ultrasonic technology, applied in the field of non-destructive testing equipment, can solve the problems of inconvenient inspection personnel, troublesome carrying, and affecting inspection operations, etc., to improve stability and interaction effects, ensure normal coating, and facilitate cleaning operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

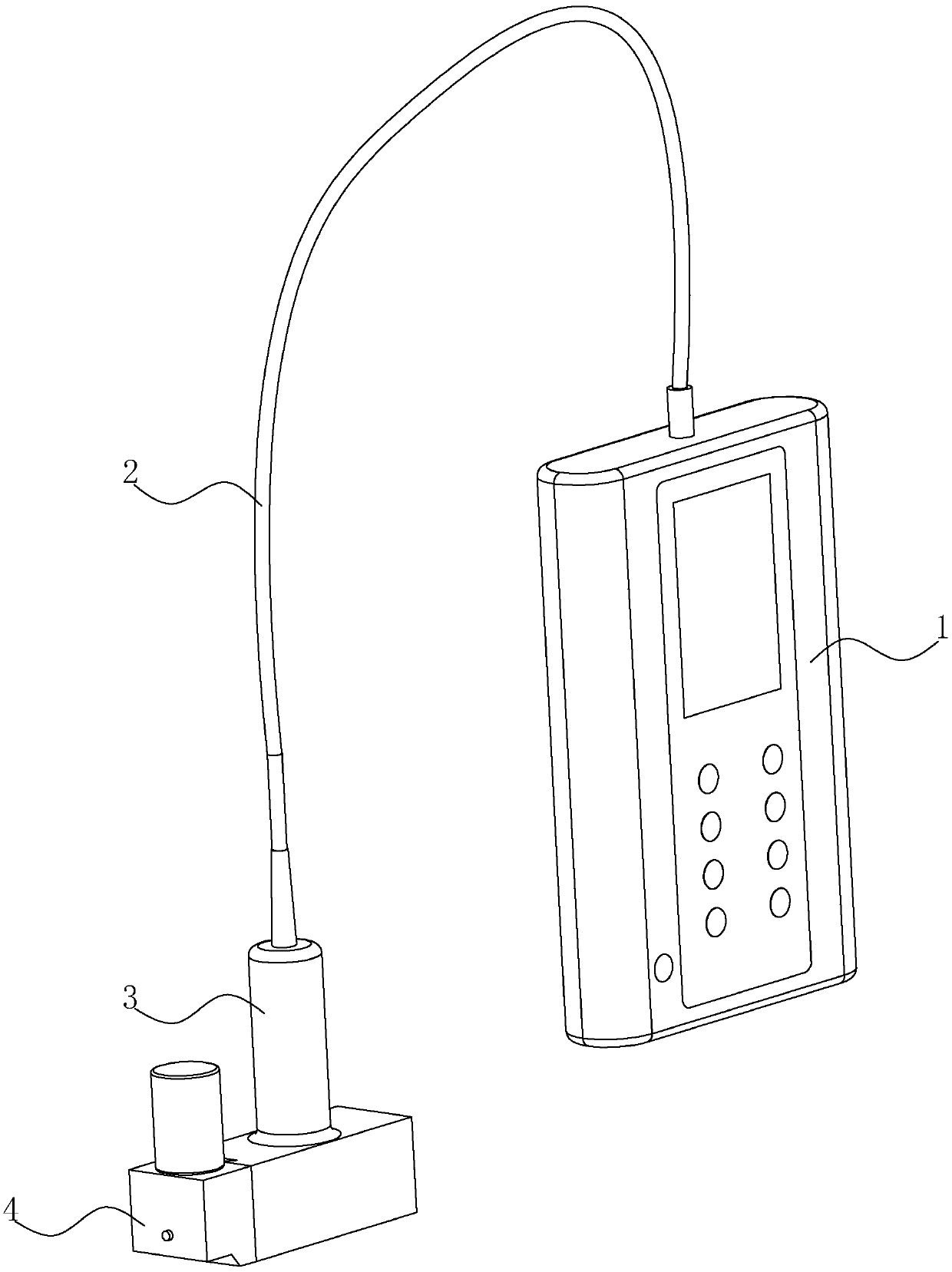

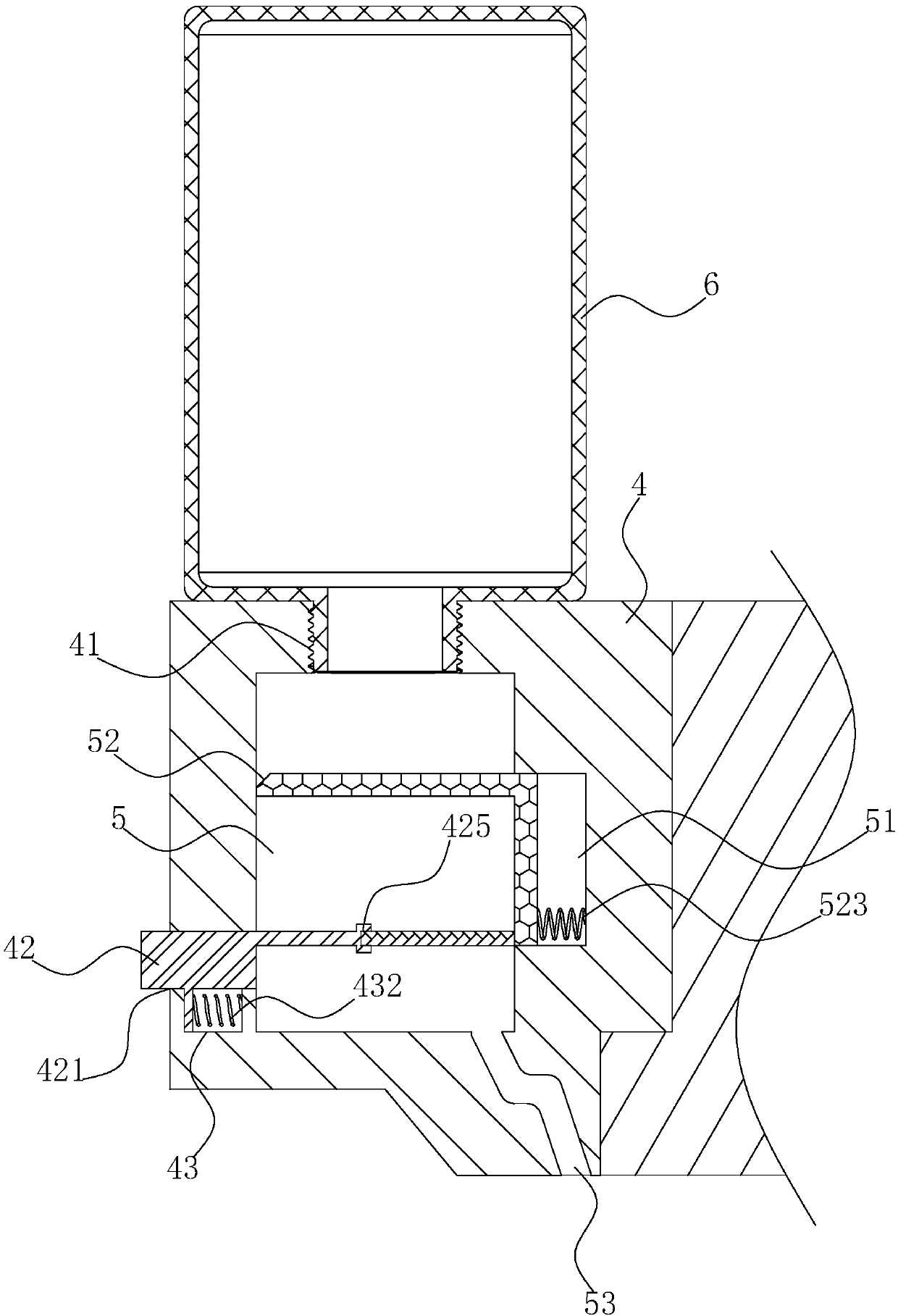

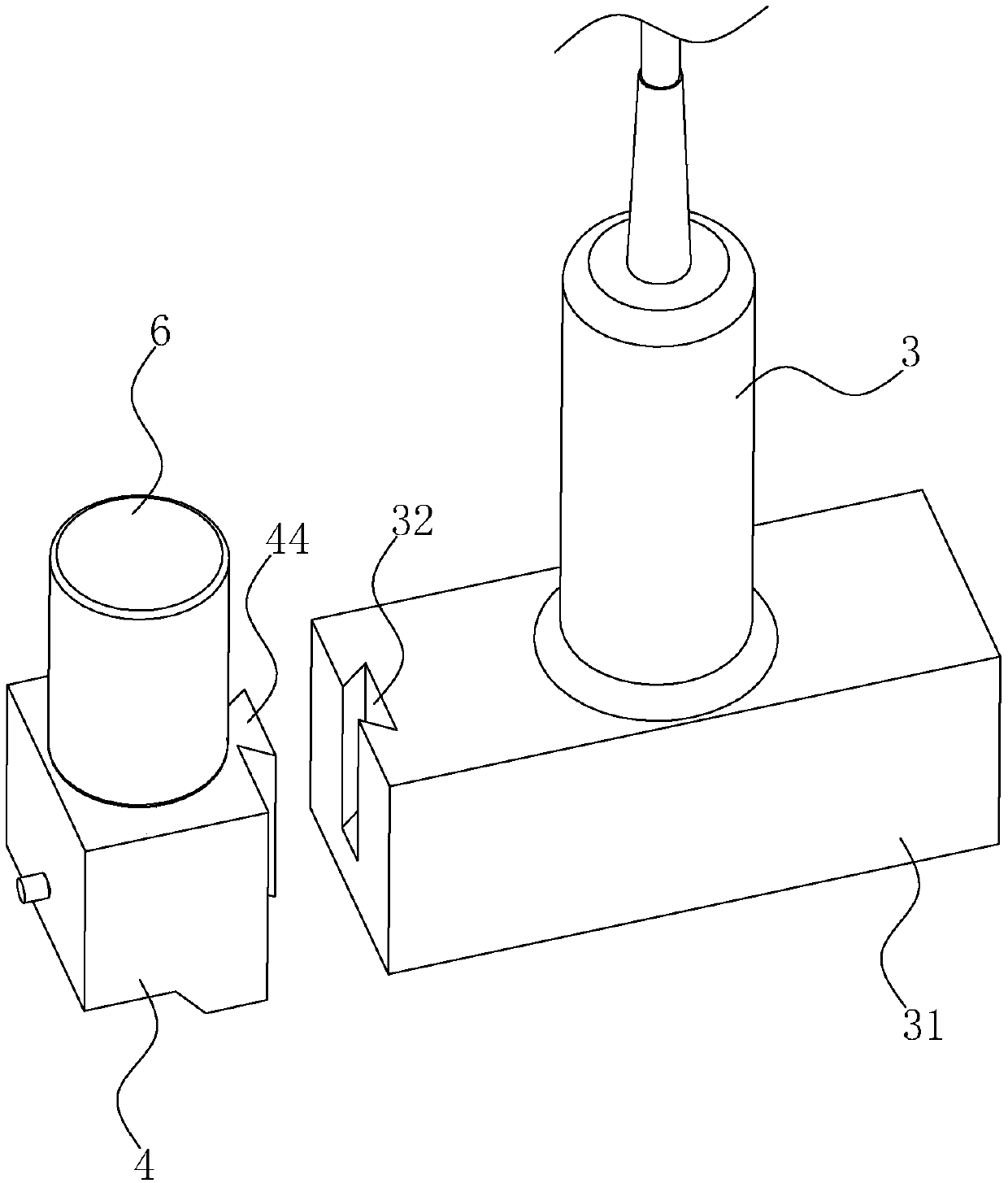

[0036] An embodiment, an ultrasonic flaw detector, such as figure 1 , 2 As shown, it includes a detection host 1, a transmission line 2 connected to the detection host 1, and a probe 3 detachably connected to the end of the transmission line 2. The probe 3 is provided with a placement seat 4 on the side wall of the housing, and the placement seat 4 is provided with a housing Cavity 5, the top of the placement seat 4 is provided with a threaded through hole 41 communicating with the containing cavity 5, the threaded through hole 41 is threadedly connected with a solvent bottle 6 containing a couplant; the placement seat 4 is located in the cavity on the side of the containing cavity 5 A sliding groove 51 is provided on the side wall of the body, and a shielding assembly 52 for closing the accommodating cavity 5 is horizontally slidably arranged in the sliding groove 51; the placement seat 4 is located on the side wall of the cavity on the other side of the accommodating cavity 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com