Combined beam column joint design method

A technology of beam-column joints and design methods, applied in the field of civil engineering, can solve problems such as strong beams and weak columns, structural collapse, and no consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to better illustrate the design method of the present invention applied to composite beam-column joints, a calculation example will be used in further detail below.

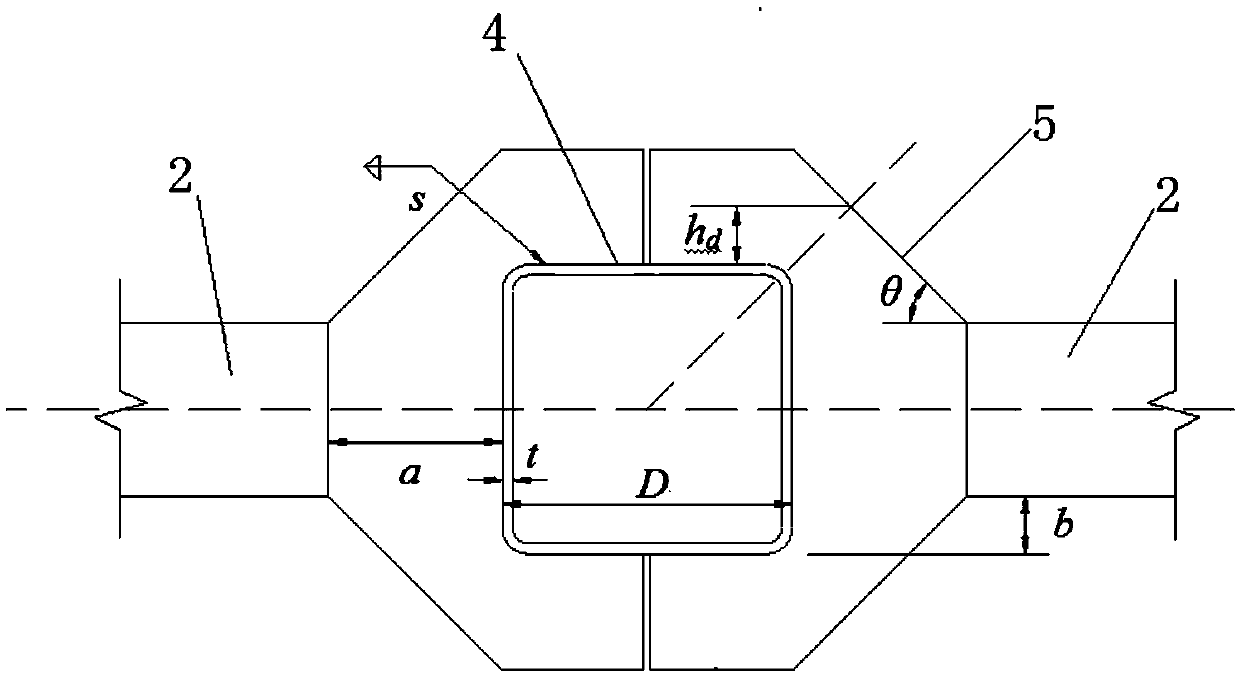

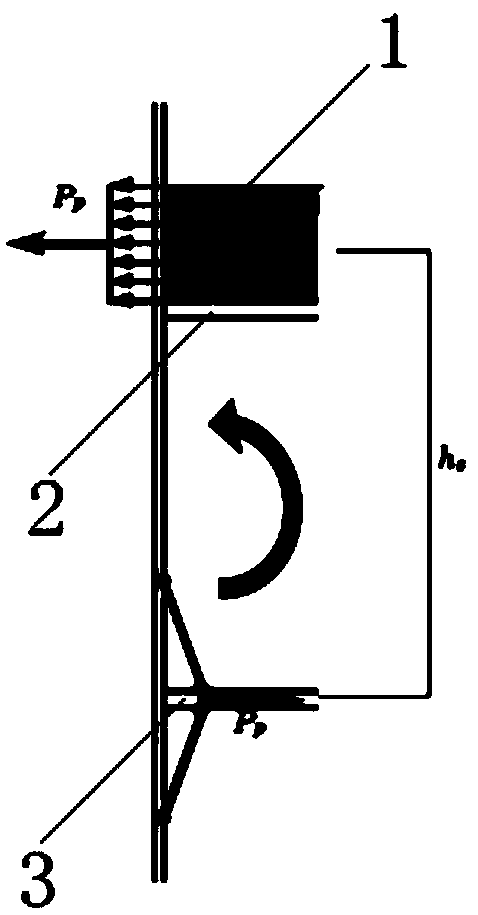

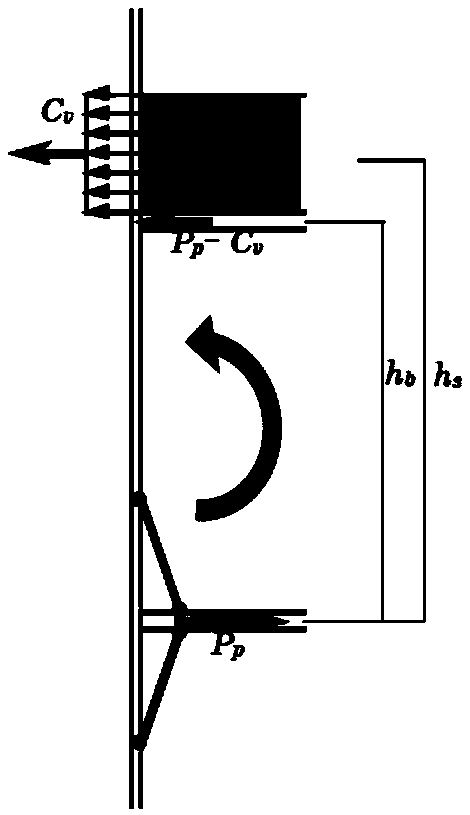

[0087] In this calculation example, the combined beam-column joint specimen is selected, and the joint calculation model is as follows: figure 1 As shown, the schematic diagram of the node computing model structure is shown in Figure 7 shown. The thickness of the floor is 85mm, the height of the beam web is 300mm, the meaning of each parameter: D is the side length of the square steel pipe column, t is the wall thickness of the square steel pipe column, t d is the thickness of the outer ring plate, s is the width of the weld, b is the distance from the outer edge of the steel pipe column to the edge of the beam flange, a is the distance from the outer edge of the steel pipe column to the edge of the outer ring plate, h d is the distance from the intersection point of the 45-degree tangent line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com