A free-form surface profile tolerance evaluation method based on CMM scanning measurement

A surface profile and evaluation method technology, applied in the direction of measuring devices, special data processing applications, complex mathematical operations, etc., can solve problems such as difficult to ensure comprehensive reflection of processing information, and achieve the effects of improved efficiency, guaranteed accuracy, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

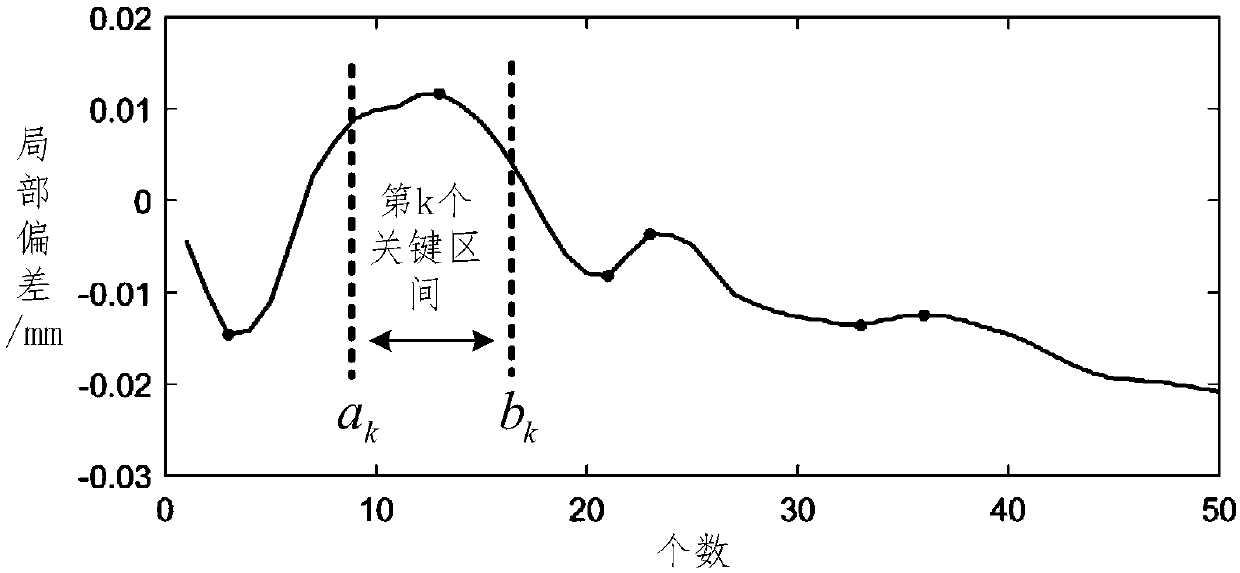

[0041] The present invention provides a method for evaluating the profile degree of a free-form surface based on CMM scanning measurement, specifically as follows:

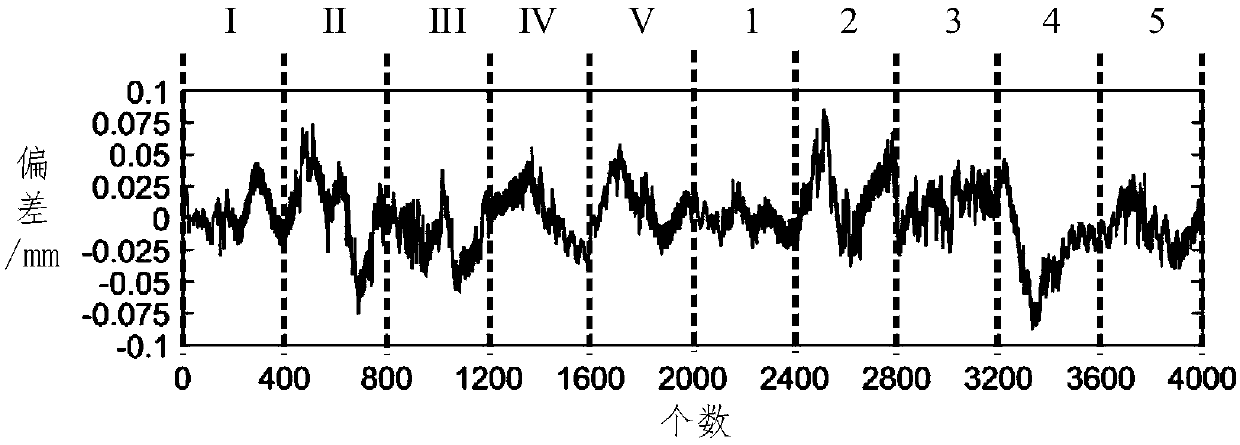

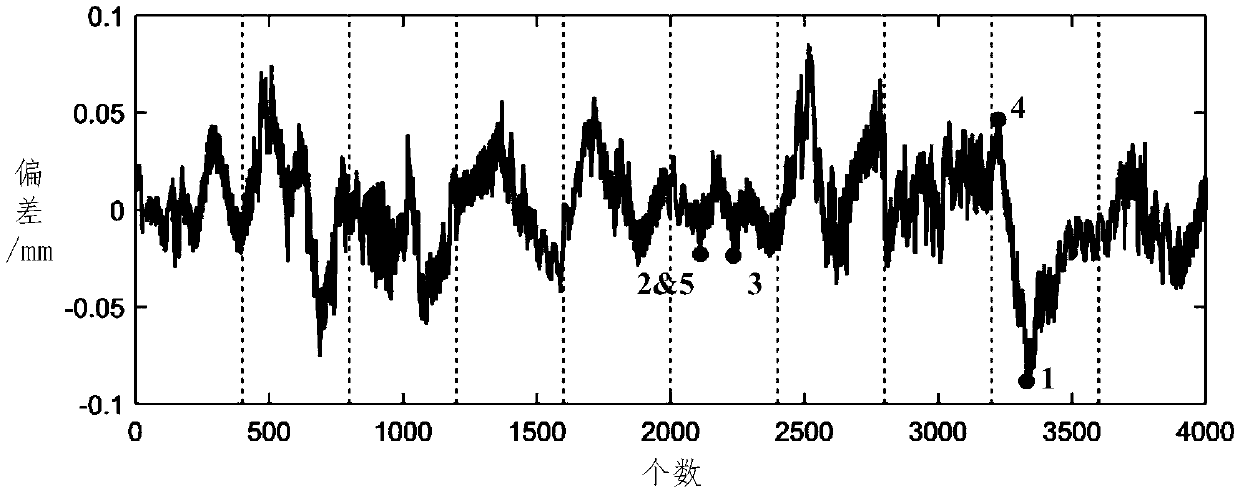

[0042] 1. Obtain the deviation curve

[0043] Sampling was performed on Daisy 8106HA CMM (AC-DMIS software), MPE E ≤(1.7+L / 330)μm, MPE P ≤1.7μm, and equipped with Renishaw PH10M (SP25-2) probe, the part is an S specimen processed by the side milling of a five-axis CNC machine tool, and 10 scanning lines containing 4000 measurement points are evenly distributed along the v direction on the surface. The deviation between the measurement point and the design surface is calculated using the surface segmentation method, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com