A kind of composite ternary positive electrode material and preparation method thereof

A cathode material and a technology for each element, applied in the field of composite ternary cathode materials and their preparation, can solve the problems affecting the high rate and cycle performance of the material, reduce the safety performance of the battery, accelerate the consumption of the electrolyte, etc., achieve good application prospects, improve Safety performance and capacity, effect of reducing residual alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

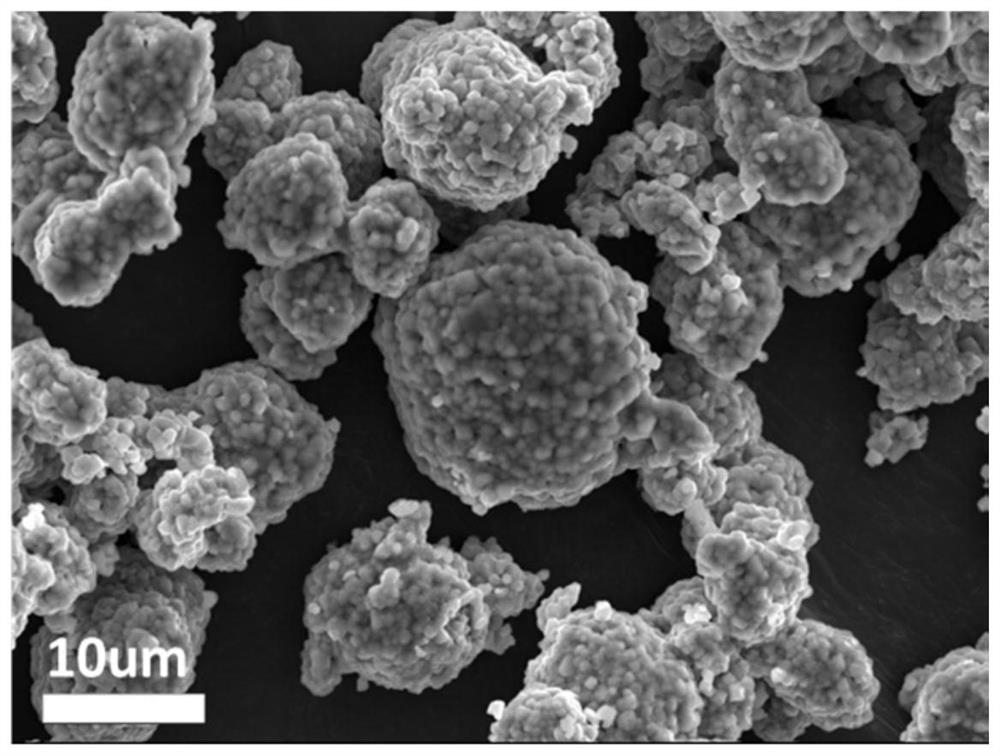

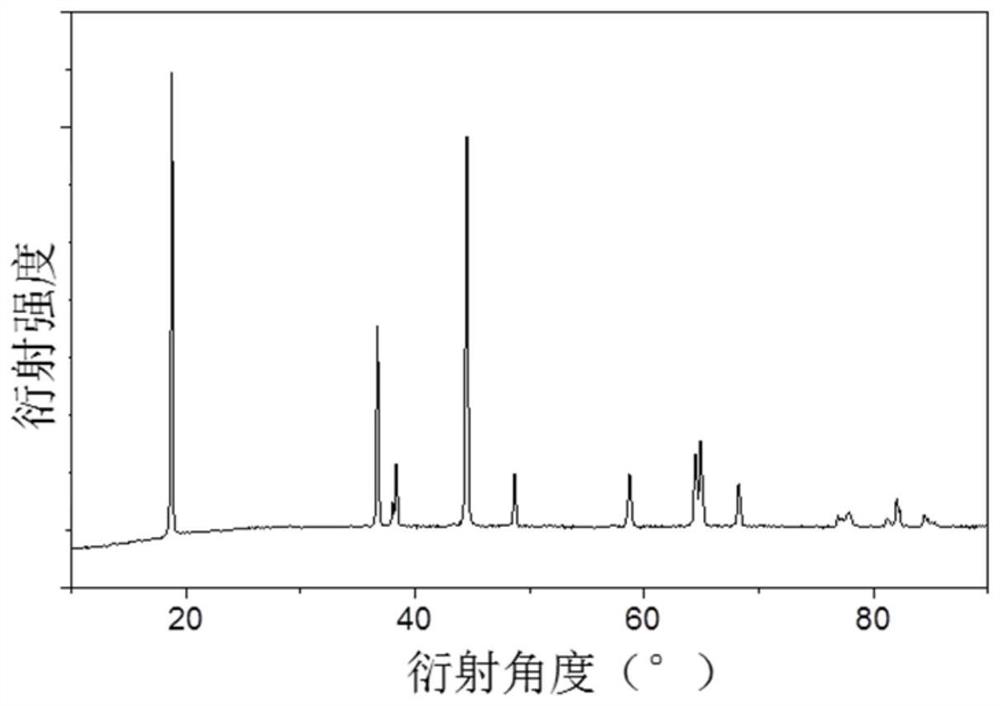

[0048] This embodiment provides a composite ternary positive electrode material, the material has a core-shell structure, the inner core is a nickel-cobalt-manganese ternary positive electrode material, and the molecular formula is LiNi 0.85 Co 0.075 Mn 0.075 O 2 ; shell is niobate, molecular formula is TiNbO 3 , the mass fraction of the shell is 1%.

[0049] Prepare as follows:

[0050] (1) According to the ratio of each element in the molecular formula, niobium acetate and titanium nitrate are dispersed in 100 mL of deionized water, then heated to 60°C under constant temperature stirring, and aged for 14 hours to obtain a niobate precursor sol;

[0051] (2) combining the niobate precursor sol obtained in step (1) with the molecular formula of LiNi 0.5 Co 0.3 Mn 0.2 O 2 The nickel-cobalt-manganese ternary cathode materials are mixed, and the two are mixed evenly by high-speed dispersing equipment. After drying, the temperature is raised to 500 ° C for 7 hours and sint...

Embodiment 2

[0055] This embodiment provides a composite ternary positive electrode material, the material has a core-shell structure, the inner core is a nickel-cobalt-manganese ternary positive electrode material, and the molecular formula is LiNi 0.75 Co 0.1 Mn 0.15 O 2 ; the shell is niobate, the molecular formula is LaNbO 3 , the mass fraction of the shell is 2%.

[0056] Prepare as follows:

[0057] (1) According to the ratio of each element in the molecular formula, disperse niobium nitrate and lanthanum nitrate hexahydrate in 100 mL of deionized water, then heat to 30 °C with constant temperature stirring, and after aging for 24 hours, obtain a niobate precursor sol;

[0058] (2) combining the niobate precursor sol obtained in step (1) with the molecular formula of LiNi 0.33 Co 0.33 Mn 0.34 O 2 The nickel-cobalt-manganese ternary cathode materials were mixed, and the two were mixed evenly by high-speed dispersing equipment. After drying, the temperature was raised to 300 °C...

Embodiment 3

[0061] This embodiment provides a composite ternary positive electrode material, the material has a core-shell structure, the inner core is a nickel-cobalt-manganese ternary positive electrode material, and the molecular formula is LiNi 0.6 Co 0.2 Mn 0.2 O 2 ; shell is niobate, molecular formula is ZnNbO 3 , the mass fraction of the shell is 3%.

[0062] Prepare as follows:

[0063] (1) According to the ratio of each element in the molecular formula, disperse niobium acetate and zinc nitrate hexahydrate in 100 mL of deionized water, then heat to 40 °C with constant temperature stirring, and after aging for 20 h, obtain a niobate precursor sol;

[0064] (2) combining the niobate precursor sol obtained in step (1) with the molecular formula of LiNi 0.6 Co 0.2 Mn 0.2 O 2 The nickel-cobalt-manganese ternary cathode materials were mixed, and the two were mixed evenly by high-speed dispersing equipment. After drying, the temperature was raised to 400 ° C for sintering for 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com