Heat preservation and heating functional plate

A functional board and thermal insulation technology, applied in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve problems such as potential safety hazards, occupants slip and touch injuries, user burns, etc., and achieve uniform heating and thermal conversion. High efficiency and favorable heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

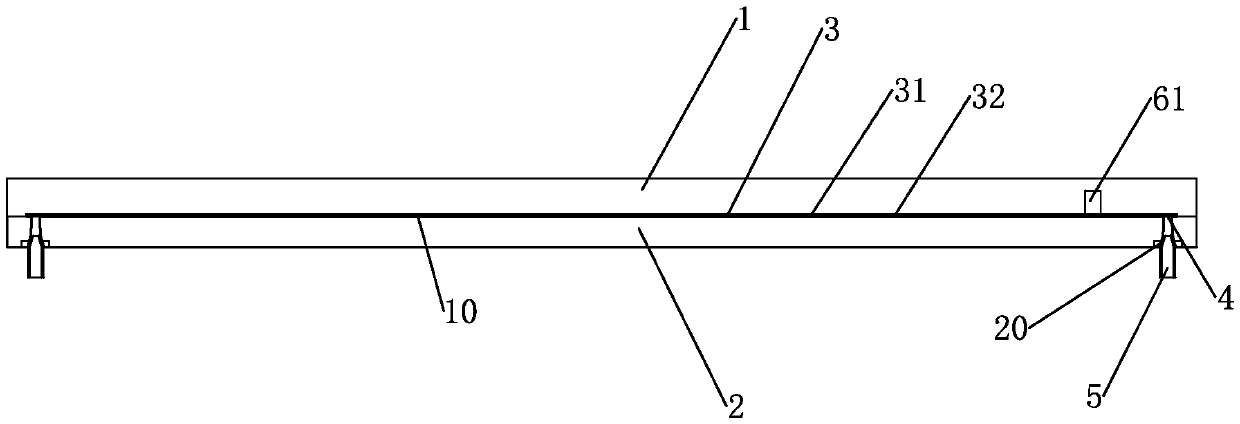

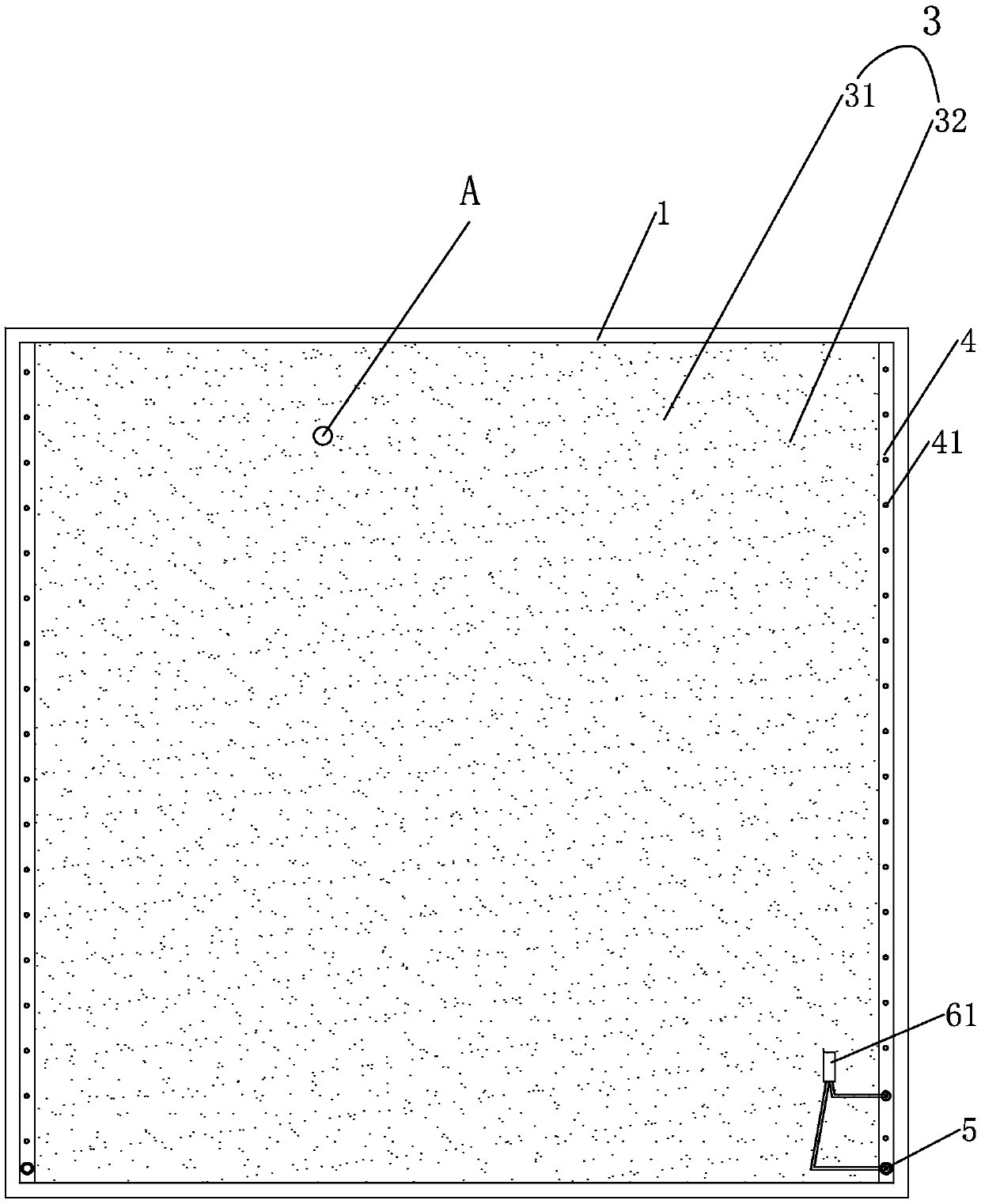

[0023] see figure 1 , figure 2 and image 3 , the present application is a thermal insulation heating function board, including an upper surface plate 1, a lower surface plate 2 and a surface heat source heating body 3. in:

[0024] The surface heat source heating body 3 is arranged between the upper surface plate 1 and the lower surface plate 2. The surface heat source heating body 3 includes a flat base body 31 and a conductive heating material 32 arranged on the outside of the flat base body 31. After the power is turned on, the heat source heating body 3 The conductive heating material 32 is used to generate heat, and at the same time, far-infrared radiation heat energy is generated outward to generate a thermal field in the use space, so as to produce a warm effect in the use space, so as to achieve the purpose of safe heating and heating, and solve the problem of poor furnace and heating safety. question.

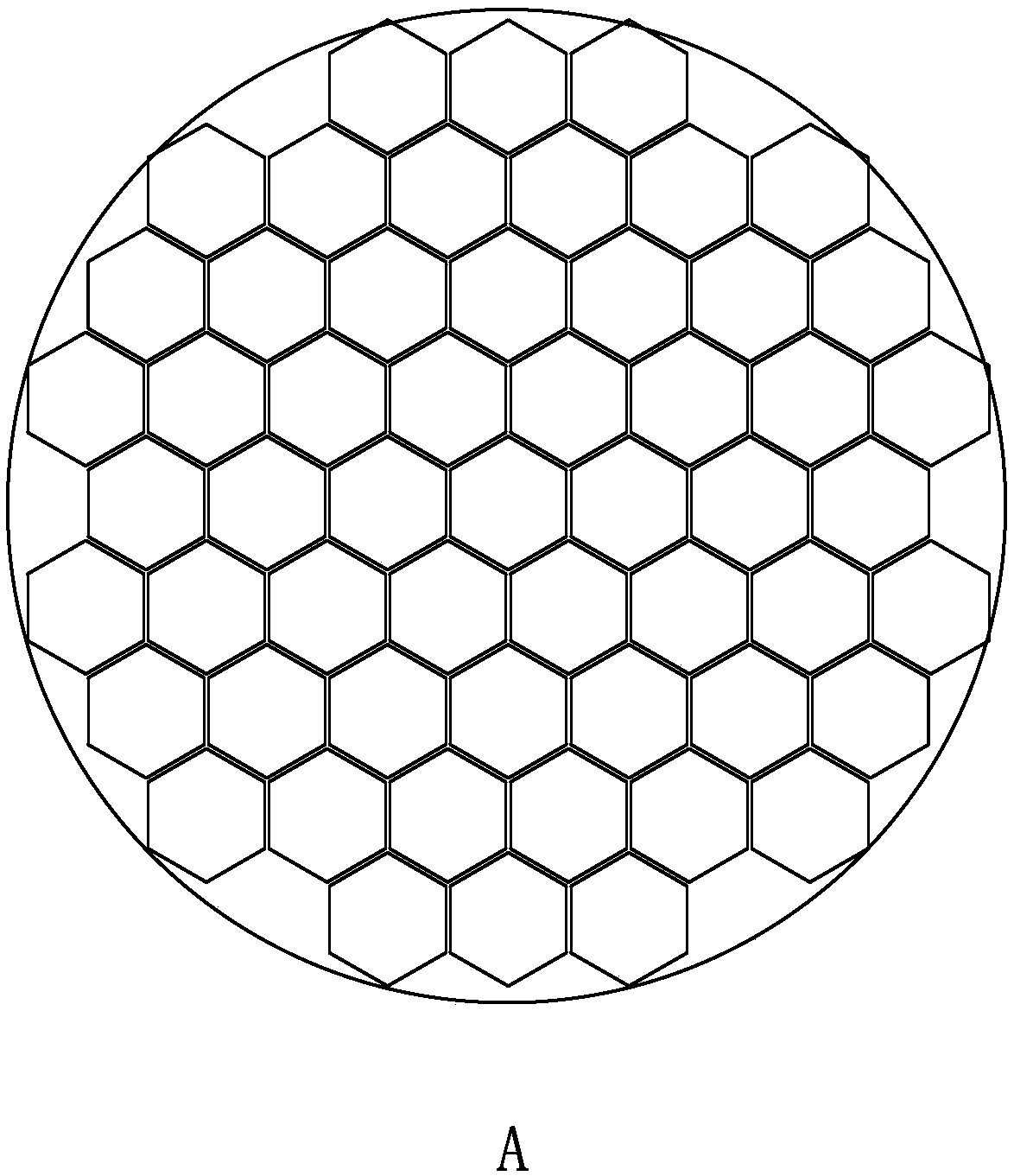

[0025] The conductive heating material 32 forms a regular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com