Bearing shell for half-shell bearing, and half-shell bearing and use thereof

A bearing shell and bearing technology, applied in the direction of rotating bearings, bearings, roller bearings, etc., can solve the problems of reducing the elasticity of the rib, reducing the elasticity, and increasing the cost, so as to reduce the thickness of the material and reduce the weight. , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

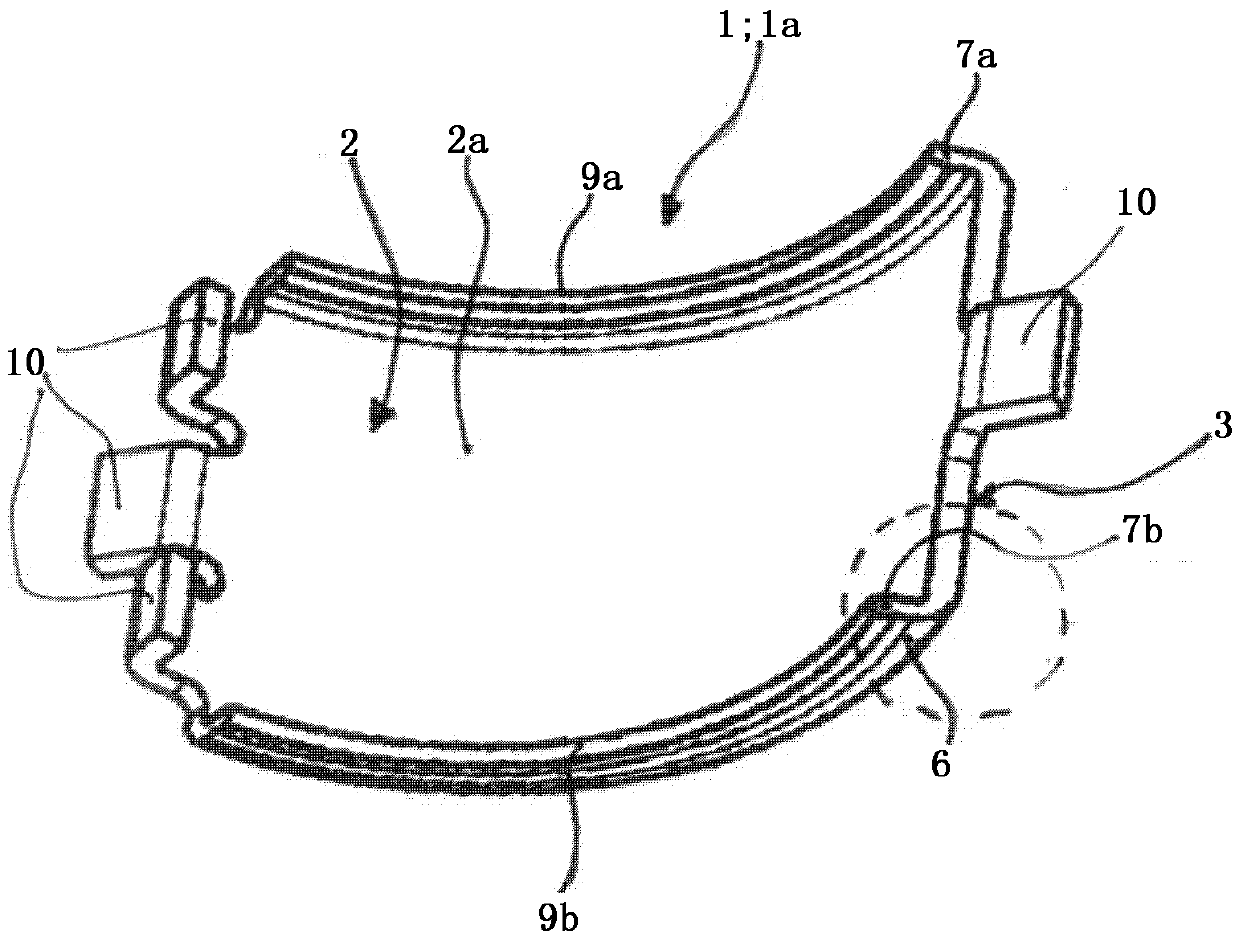

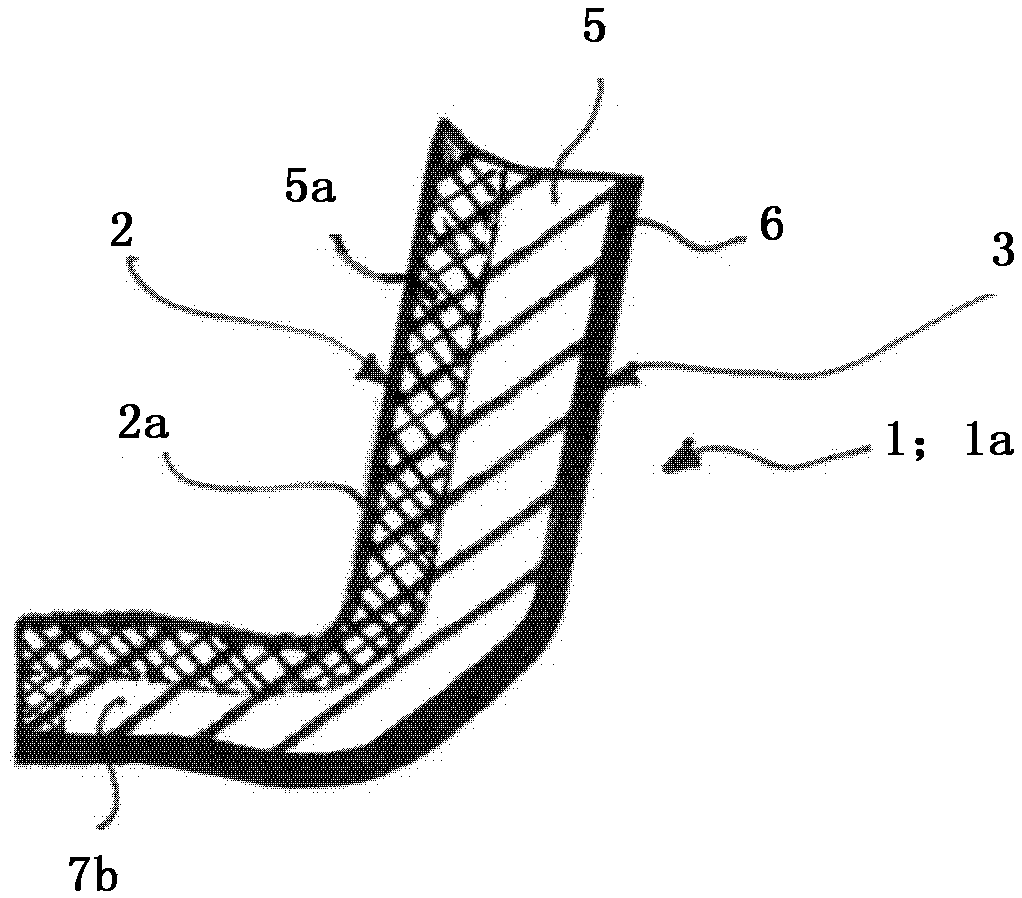

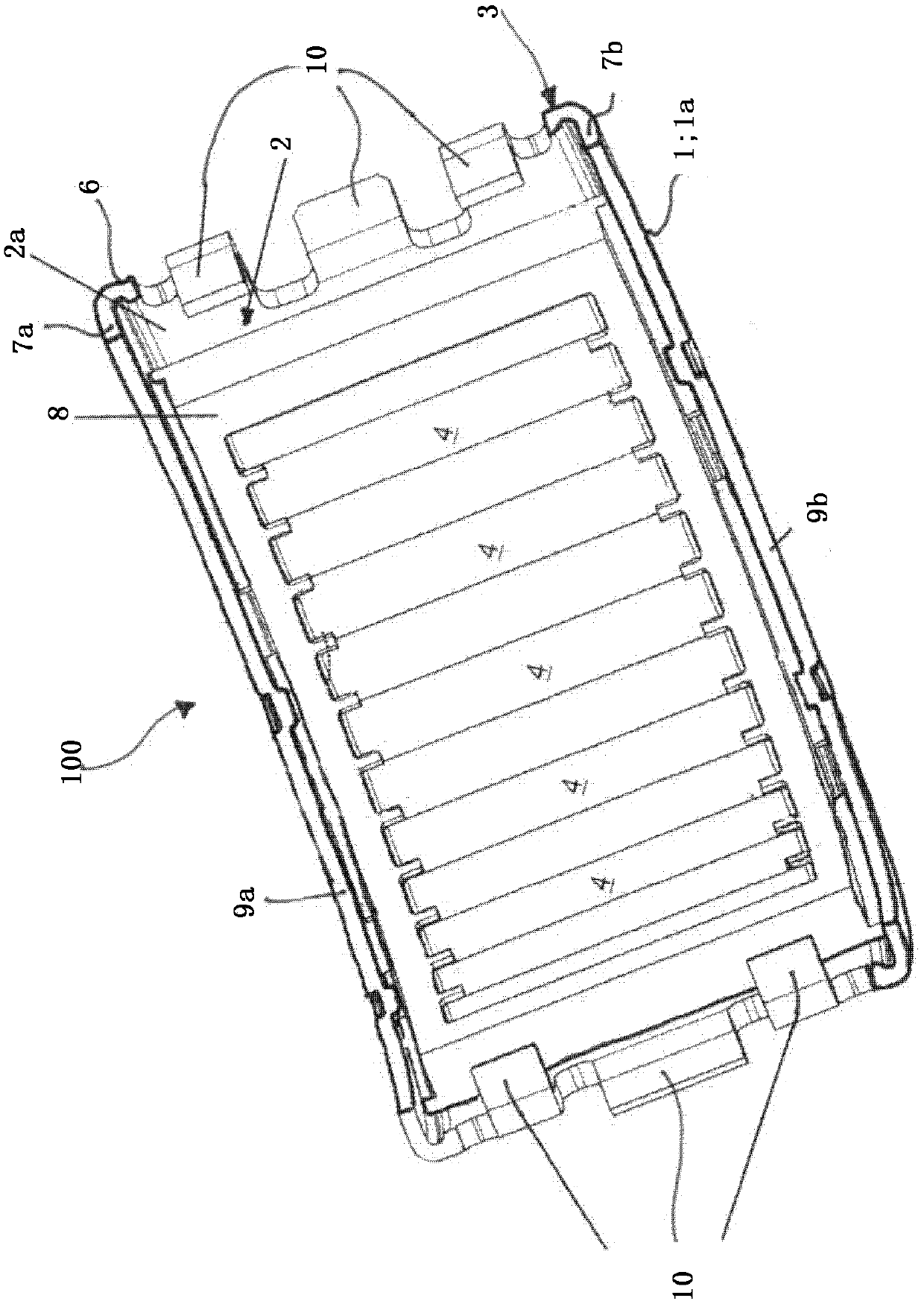

[0030] figure 1 A bearing housing 1; 1a is shown in a three-dimensional view with two longitudinal sides 9a, 9b, wherein on each of these longitudinal sides 9a, 9b a stop pointing in the direction of the raceway 2a for the rolling bodies is arranged. Sides 7a, 7b. figure 2 The cross-sectional diagram shows the basis of figure 1 An enlarged fragment of the bearing housing 1; 1a in the region of the rib 7b. The bearing shell 1; 1a is hardened by a hardening method. The bearing housing 1; 1a has a main body 5 made of steel (see figure 2 ), and on the first side 2 there is a raceway 2a for the rolling elements. On the second side 3 facing away from the first side 2, the main body 5 has a coating 6 of a coating material, which is set up so that during the hardening method, a carbon-resistant coating is formed in the region of the second side 3. Diffusion barrier towards body 5. in accordance with figure 2 In a sectional view through the rib 7b, the hardened edge layer 5a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com