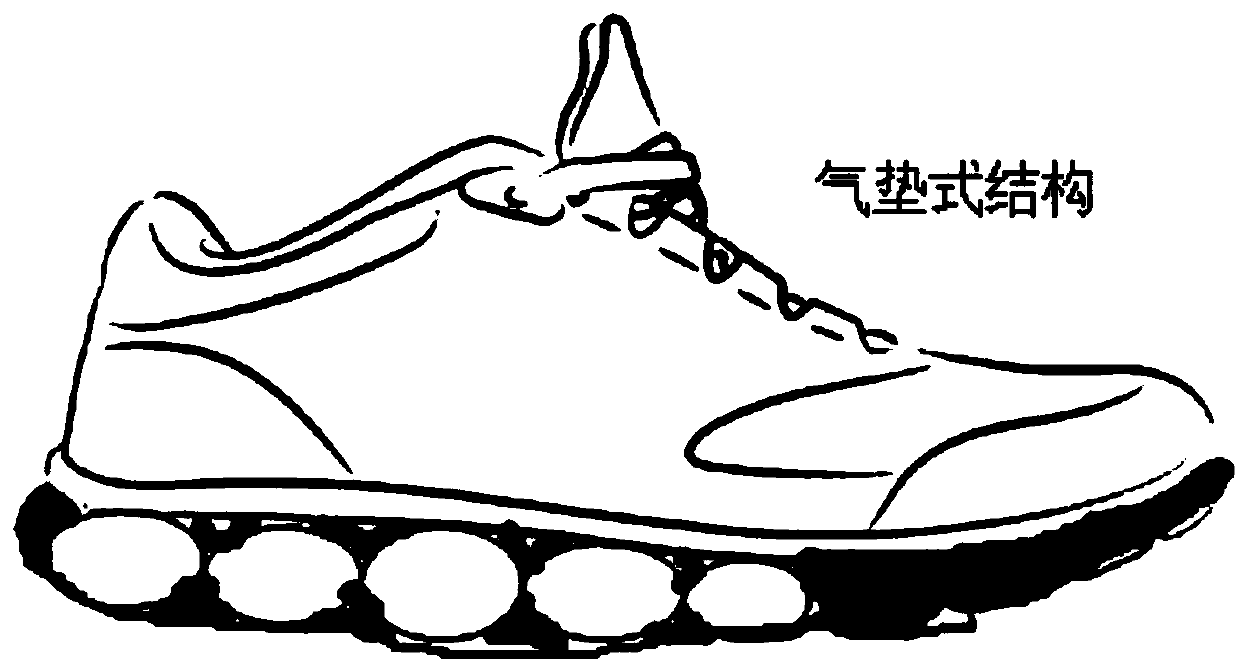

Sole for sports shoes and preparation method and application thereof

A technology for sports shoes and soles, applied in the field of footwear products, can solve the problems of high cost, insignificant experience effect, unfavorable application, etc., and achieve the effects of low cost, reduced weight, and favorable application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention provides a kind of preparation method of above-mentioned sports shoe sole, comprises the following steps:

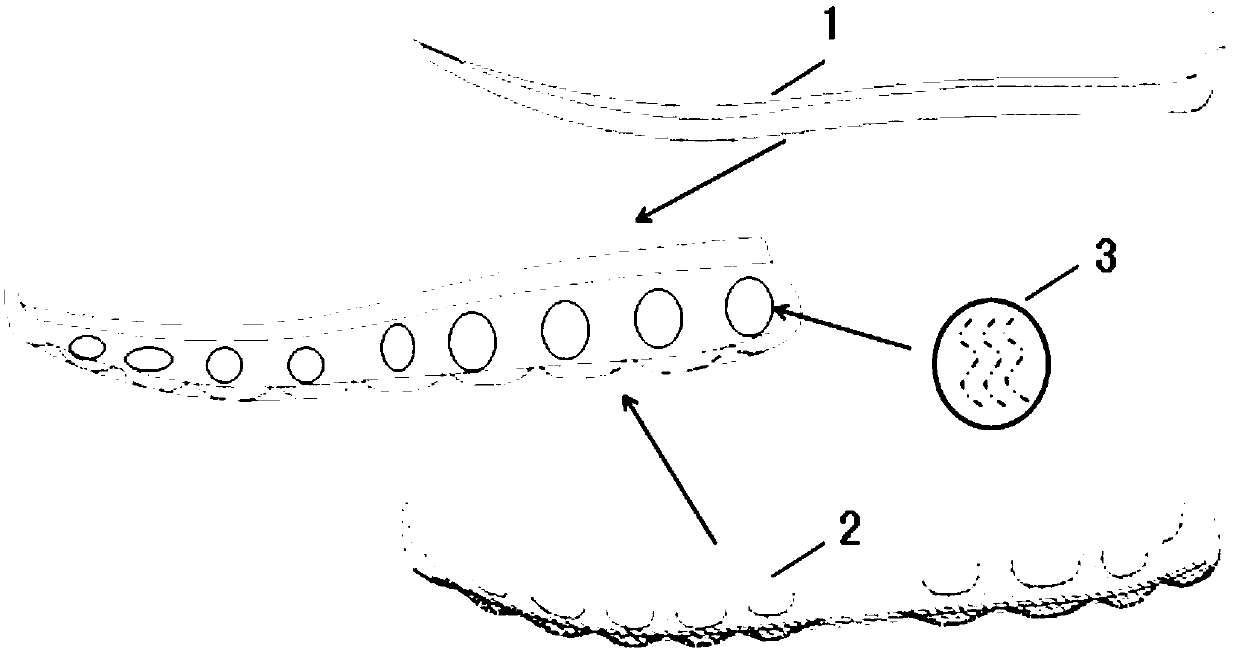

[0049] An upper bottom blank and a lower bottom blank are respectively provided; the upper surface of the upper bottom blank covers the entire sole of the foot, and a plurality of grooves are reserved in the lower bottom blank, and the plurality of grooves are located at the first far The metatarsal to the first metatarsal and the second middle phalanx area, the metatarsal area of the forefoot, and the calcaneal area at the heel;

[0050] Assemble the upper and lower base blanks, place chemical foaming agents or physical barrier substances in the reserved multiple grooves, and then fire them to form a plurality of closed air cavities The midsole is finally prepared to obtain the sole of the sports shoe.

[0051] In the embodiment of the present invention, the upper bottom blank and the lower bottom blank are respectively ...

Embodiment 1

[0060] Through the injection machine, the upper and lower bottom blanks are prepared respectively. The upper bottom blank is correspondingly formed into an upper bottom part, and its upper surface shape covers the entire sole of the foot; the lower bottom blank is correspondingly formed into a lower bottom part. Wherein, the lower bottom blank is reserved with a plurality of grooves, which correspondingly form a closed air cavity, which is located at the first distal phalanx to the first metatarsal and the second middle phalanx, the forefoot metatarsal area, and the heel at the heel. bone area. The materials of the upper bottom blank and the lower bottom blank are all EVA, which is called the injection foam bottom rubber material, which belongs to the IP formula, and the specific gravity of the material is 0.40g / cm 3 .

[0061] Assemble the obtained upper bottom blank and lower bottom blank, place 0.6g PU film (thickness about 0.2mm, polymerization degree between 200-400, mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com