A beating device for polishing heel fabric with pull-twist buckle for making shoes

A pull-rotary and functional technology, applied in the direction of shoemaking machinery, footwear, applications, etc., can solve problems such as friction and pressure, heel skin breakage, and inability to walk on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

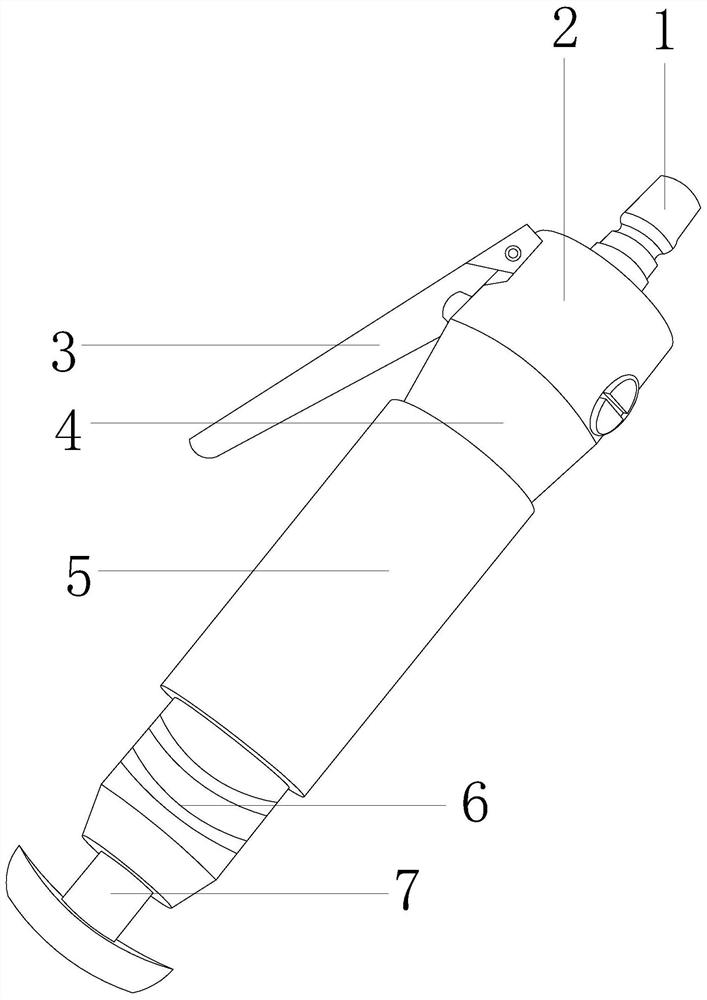

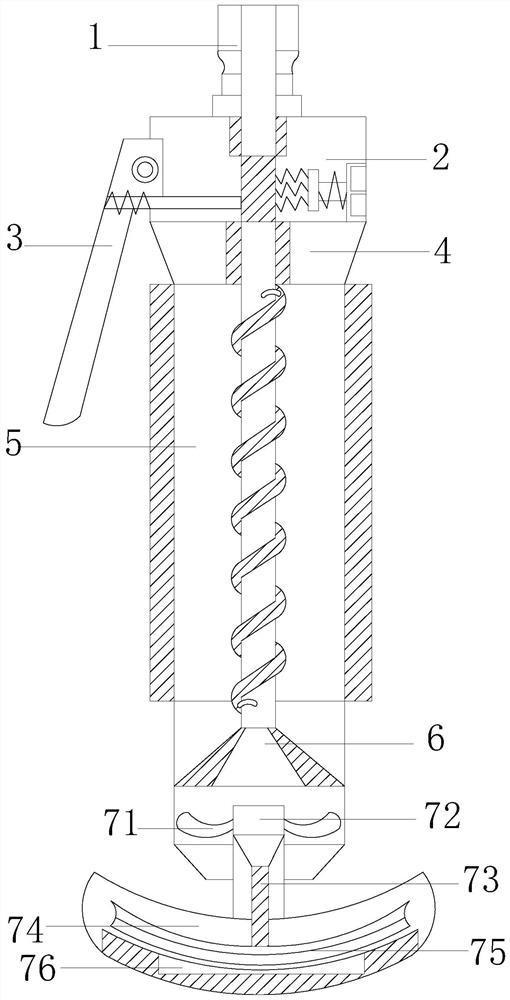

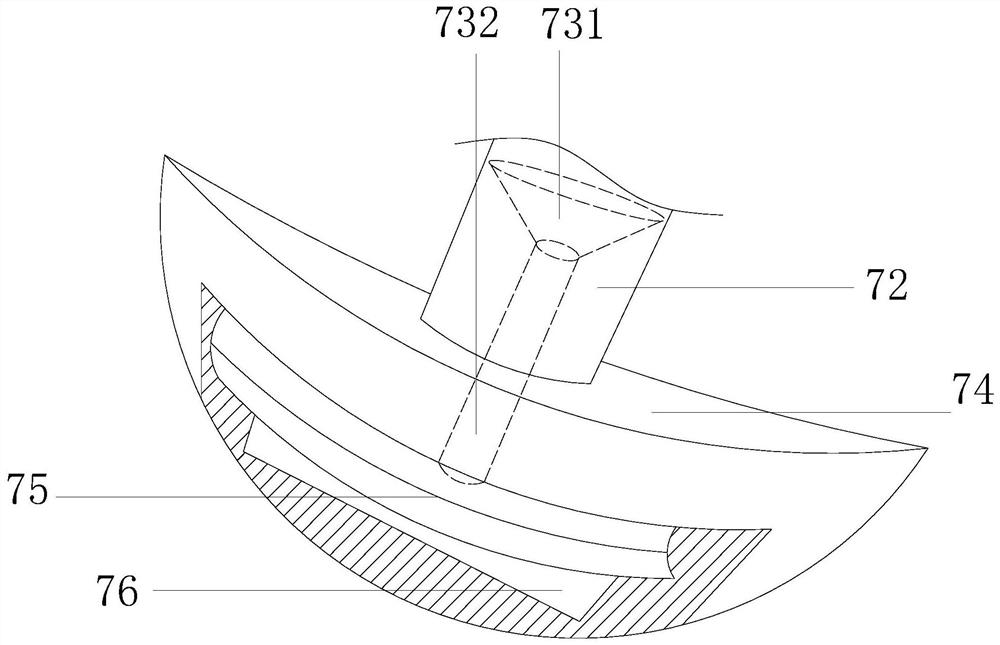

[0027] see Figure 1-Figure 6 , the present invention provides a beating device for grinding heel cloth with a pull-twist outer buckle for making shoes. Tube 5, horn exhaust tube 6, pull-twist plate frame 7, the top of the pull-twist plate frame 7 is inserted and embedded under the bottom of the horn exhaust tube 6, and the round platform column cap 4 and the horn exhaust tube 6 Nested in the upper and lower ends of the spiral straight-through tube 5 and the axes are collinear, the air pipe quick-connect cap 1 is inserted on the axis of the one-way valve seat 2, and the pressure plate rod 3 is connected to the one-way valve through a spring. The port seat 2 is mechanically connected, the trachea quick-connect cap 1, the one-way valve port seat 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com