Patents

Literature

42results about How to "Avoid frictional situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

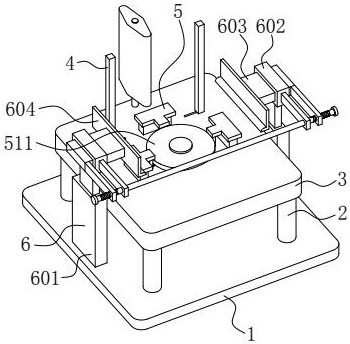

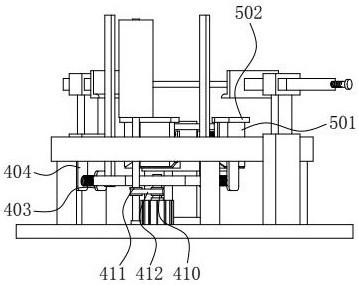

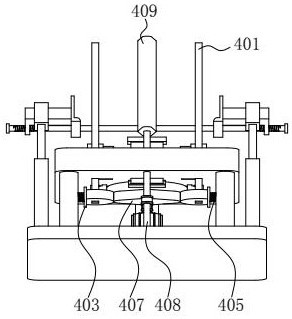

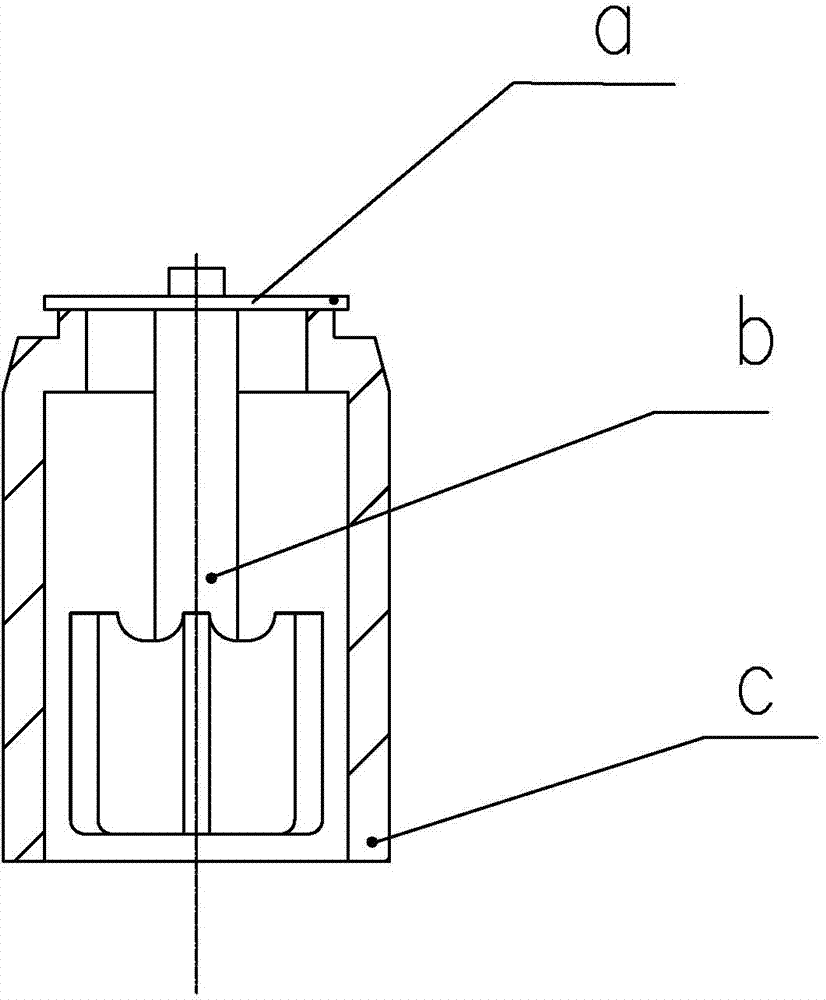

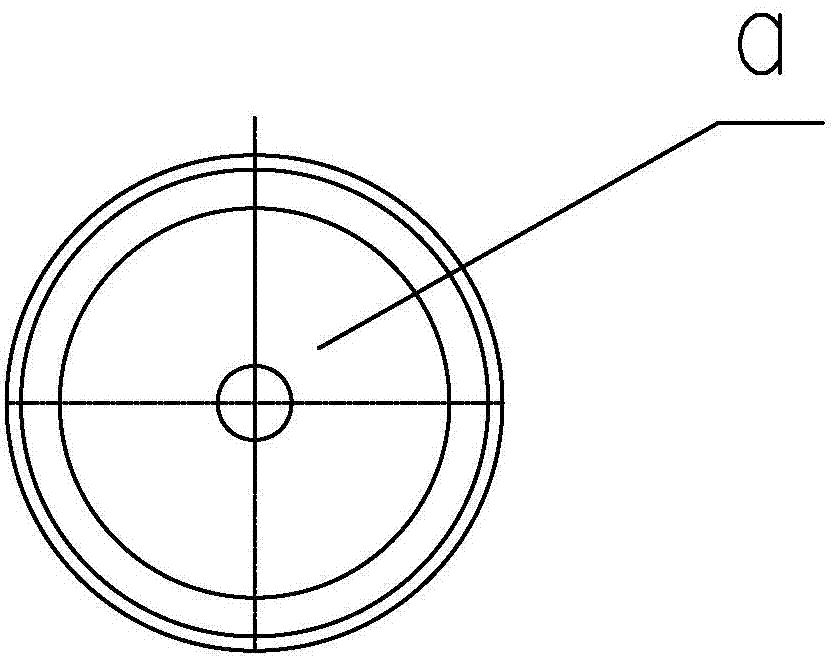

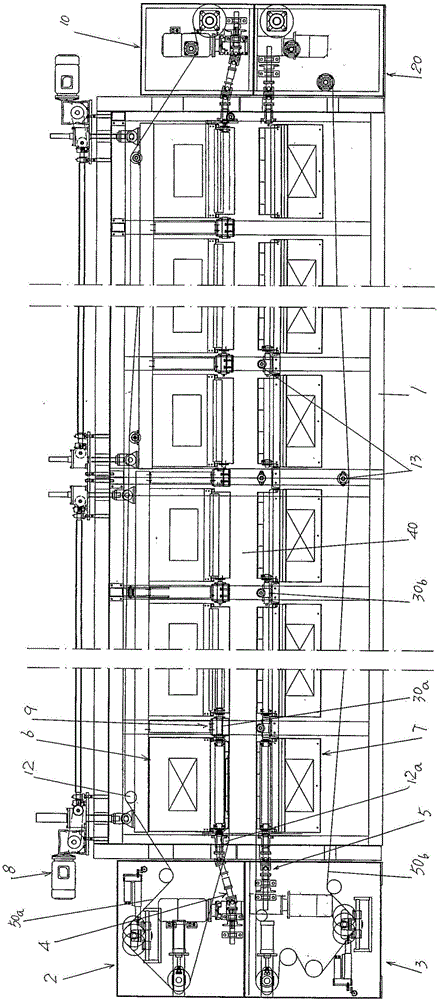

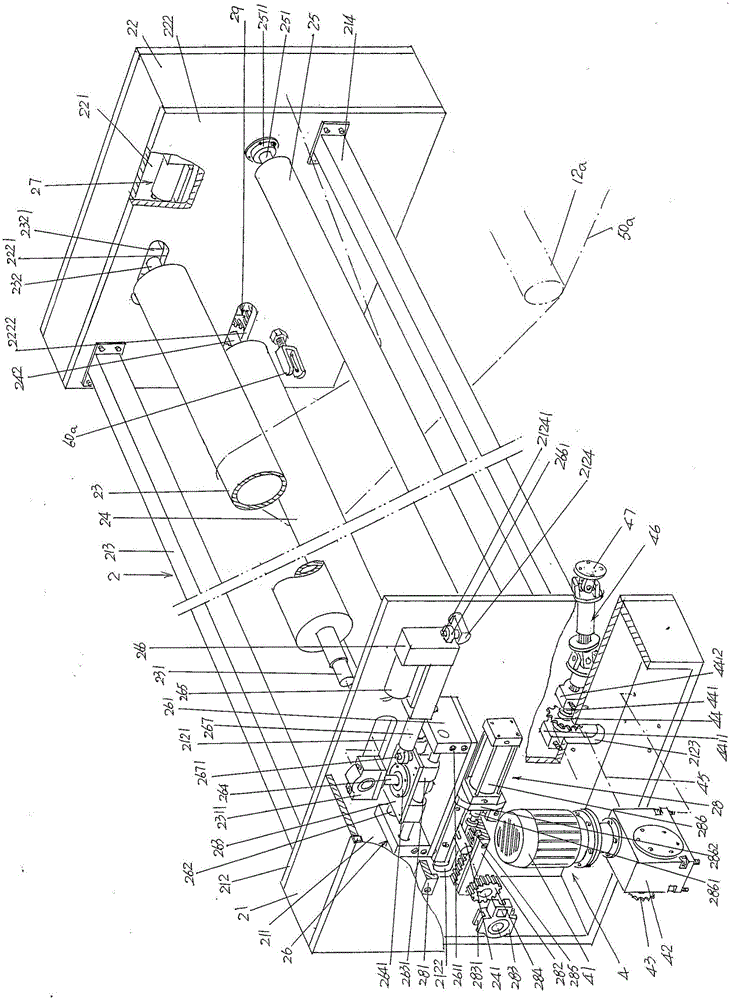

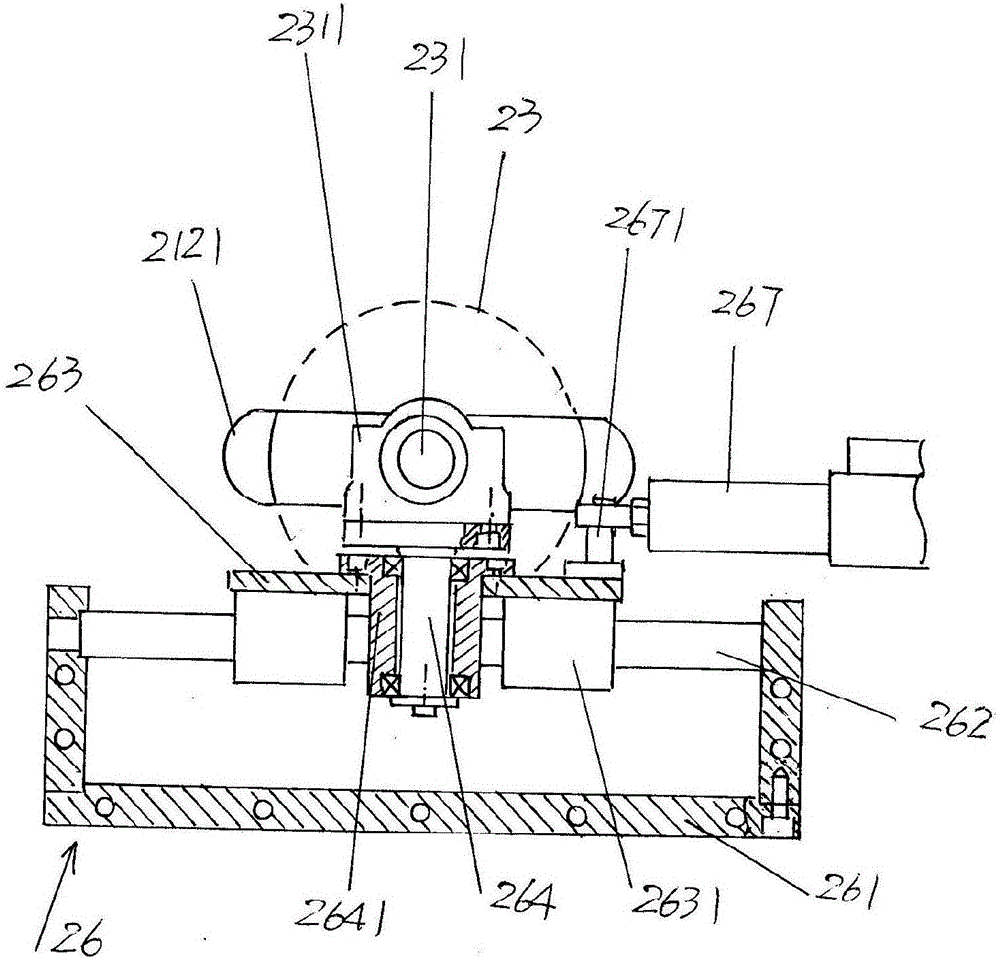

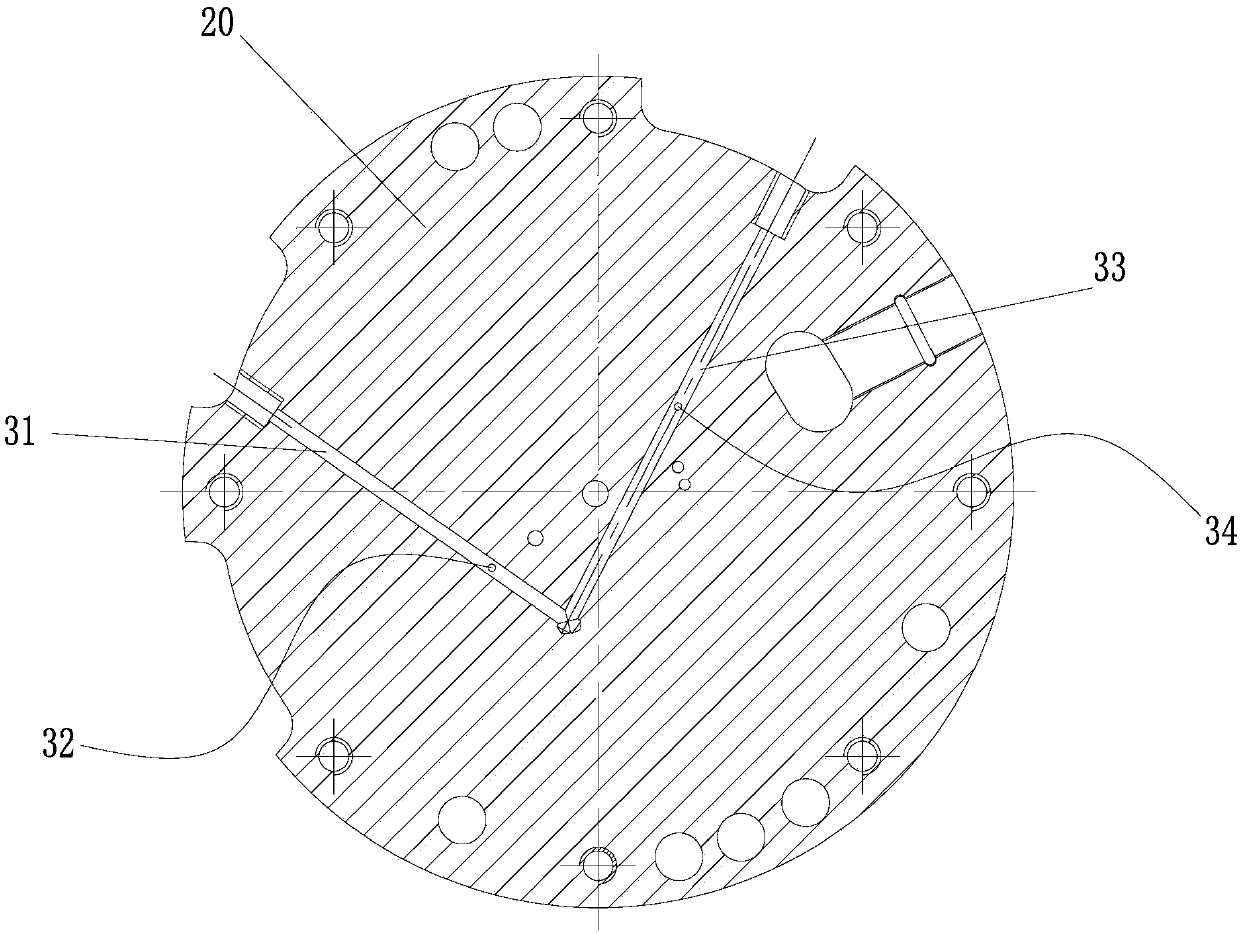

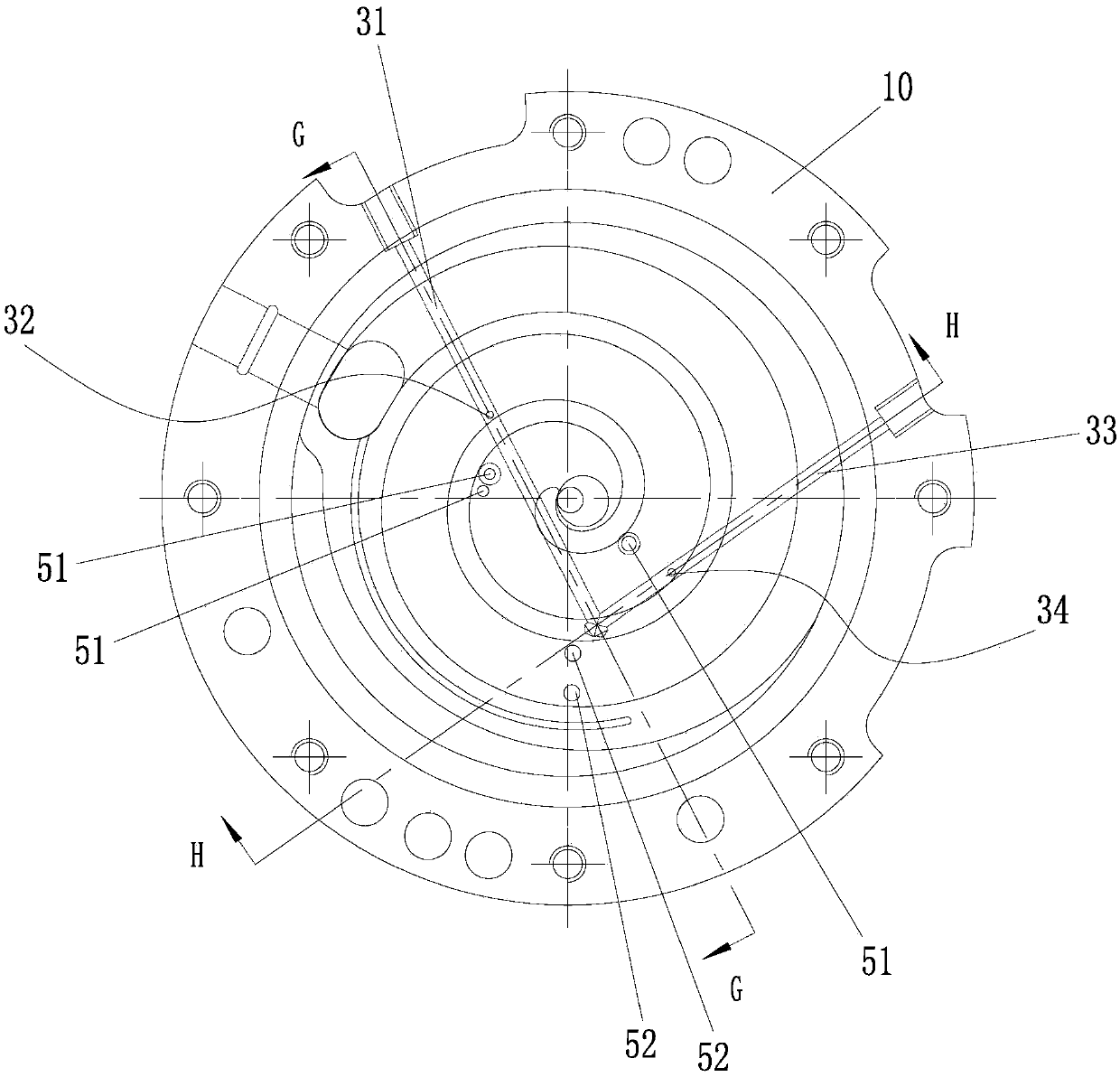

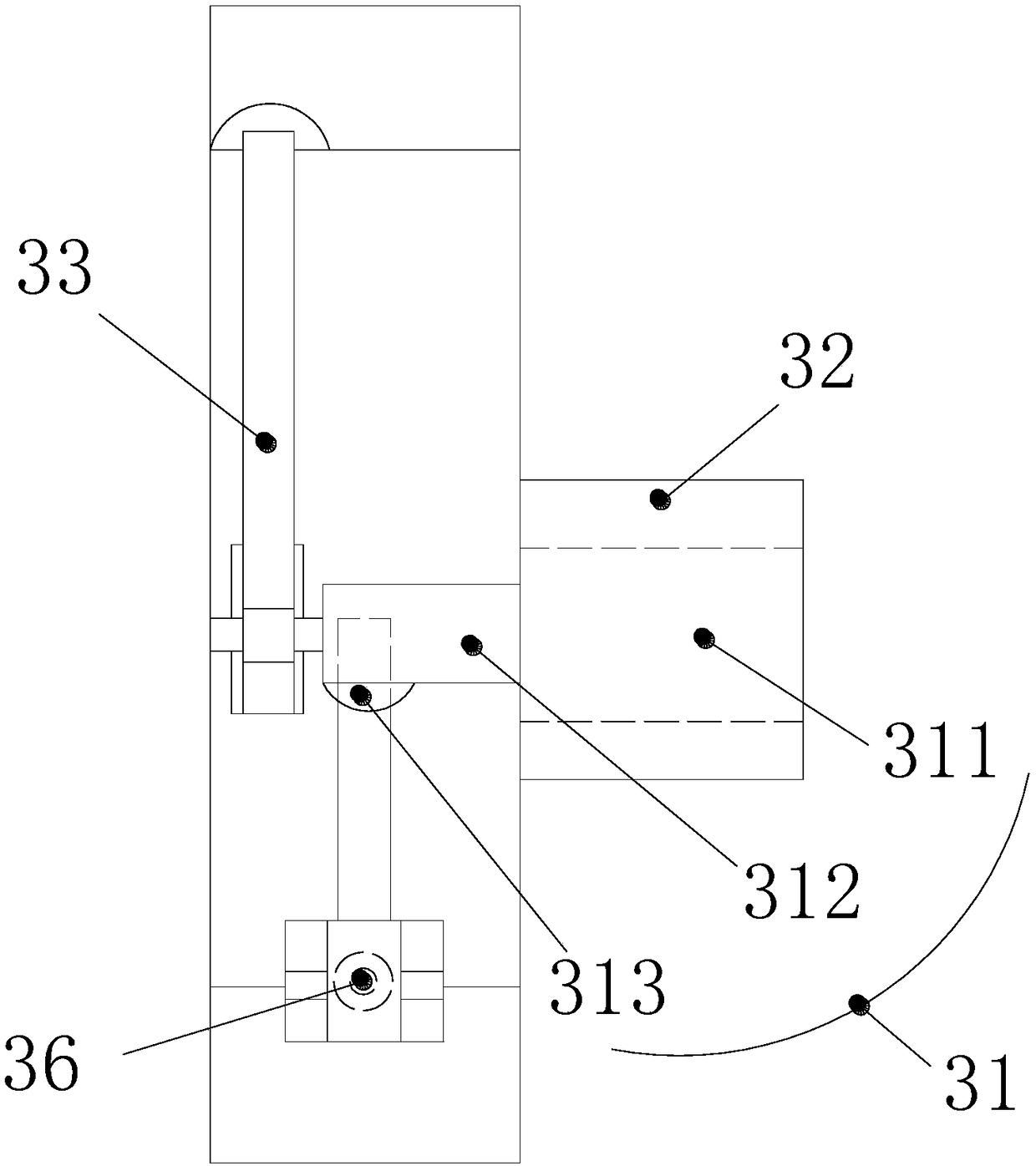

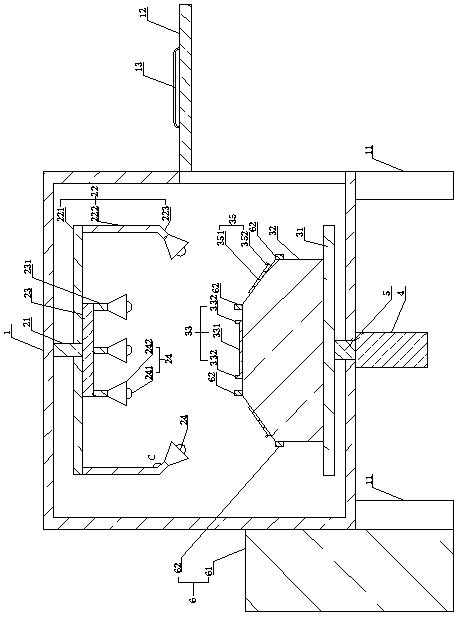

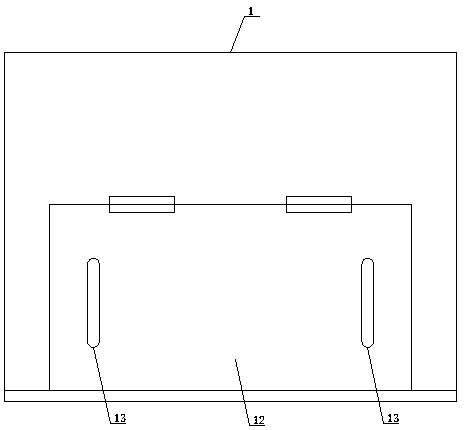

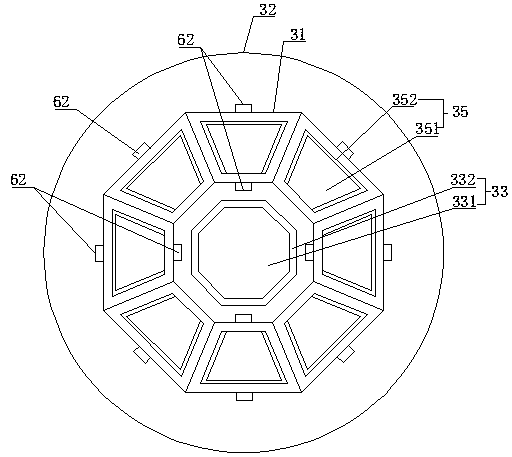

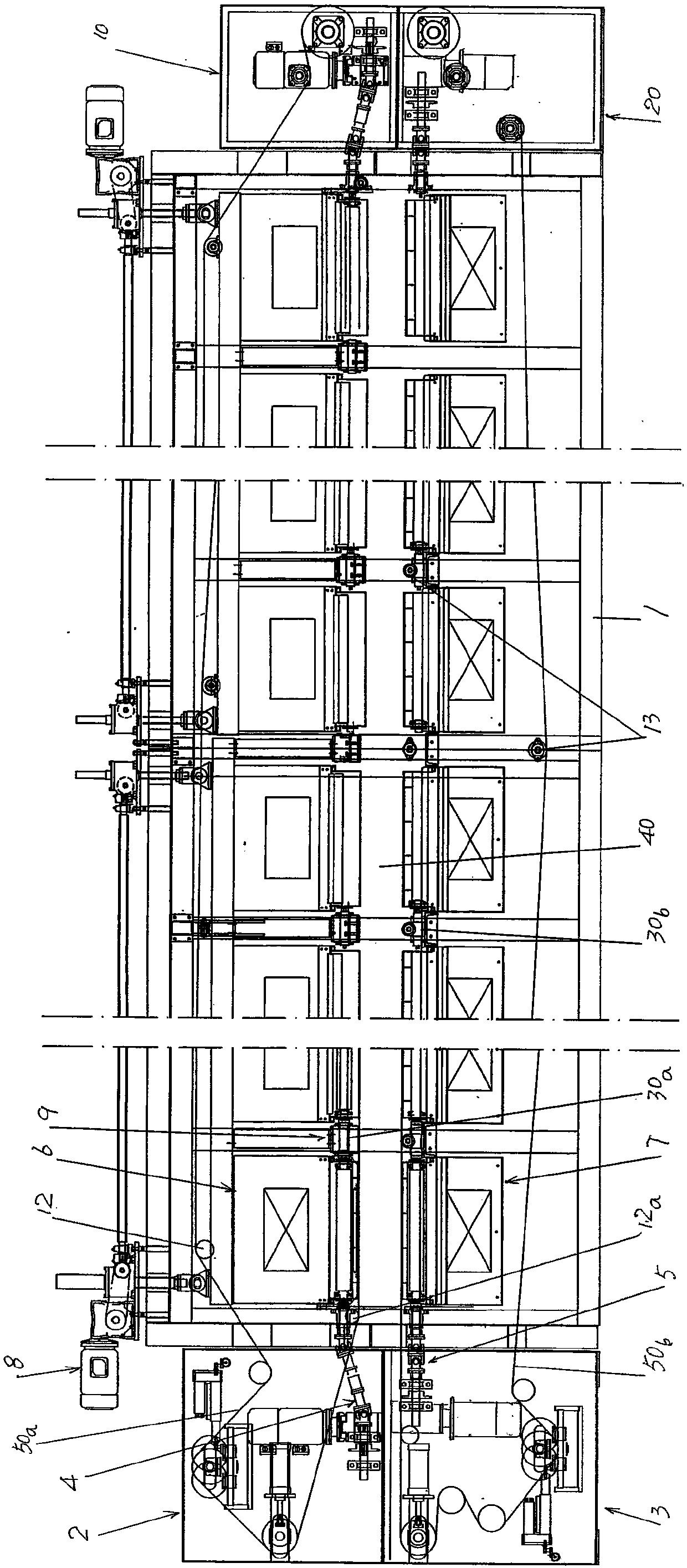

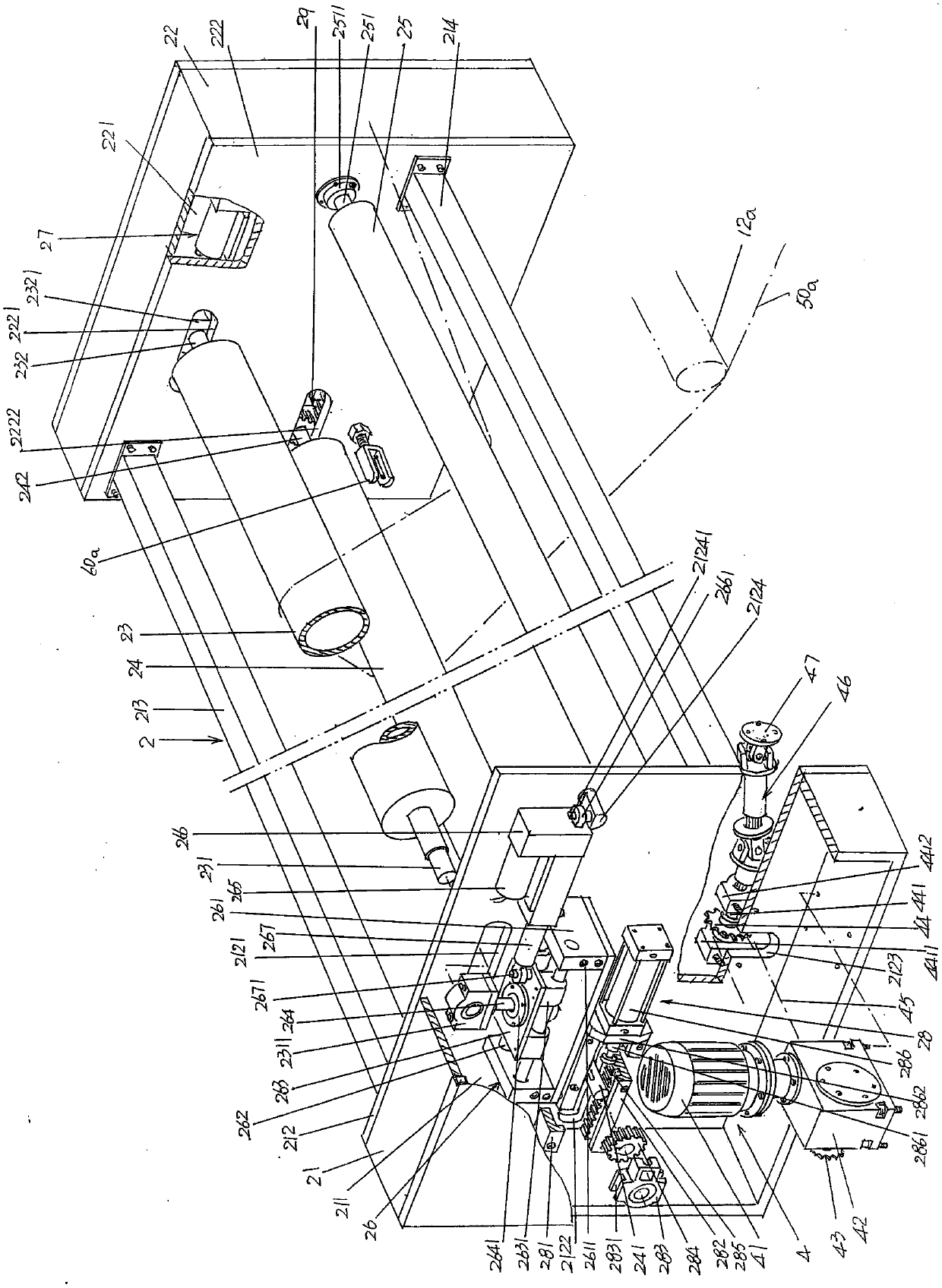

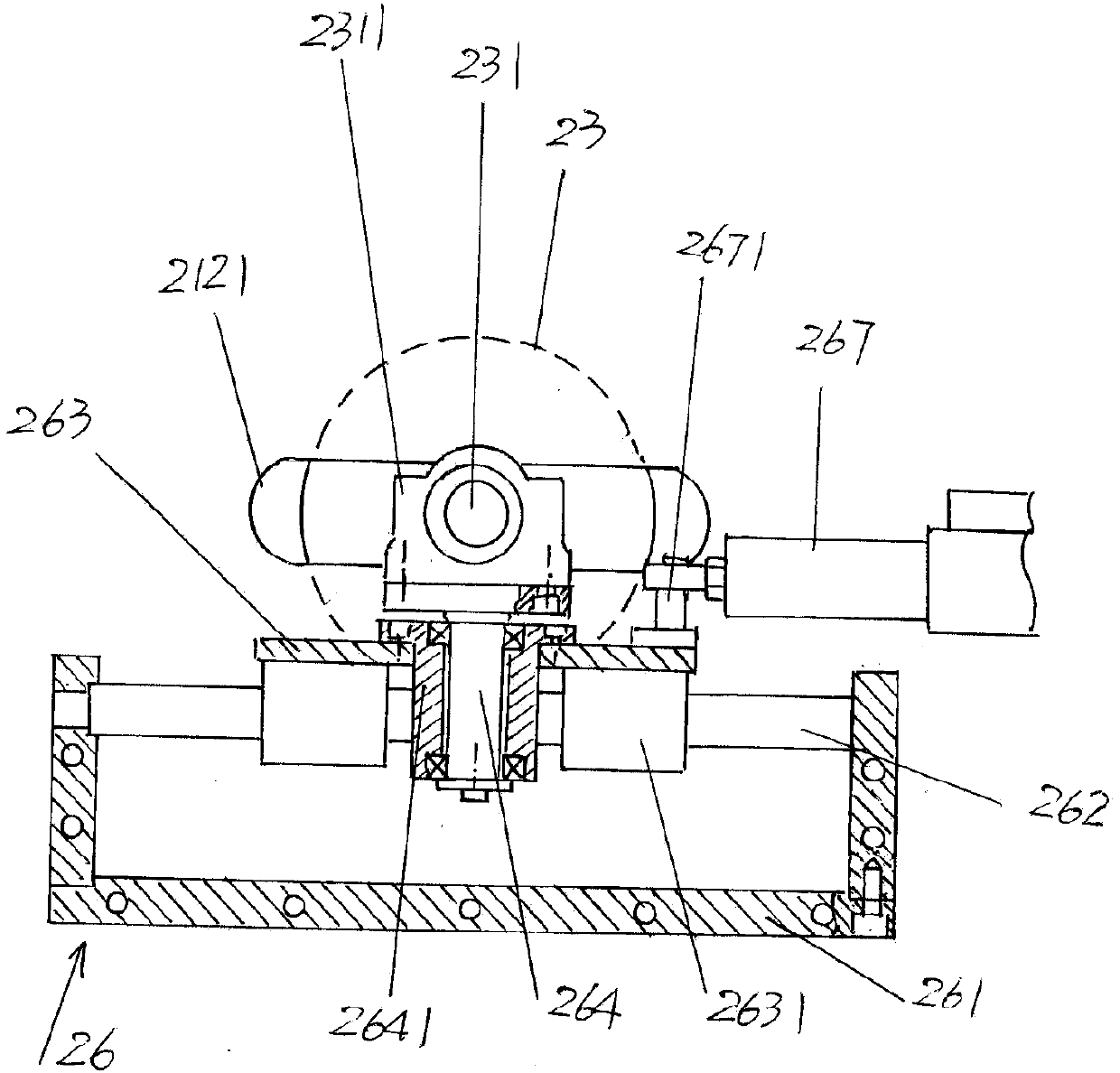

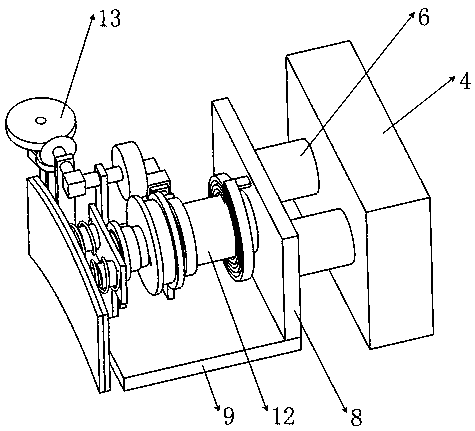

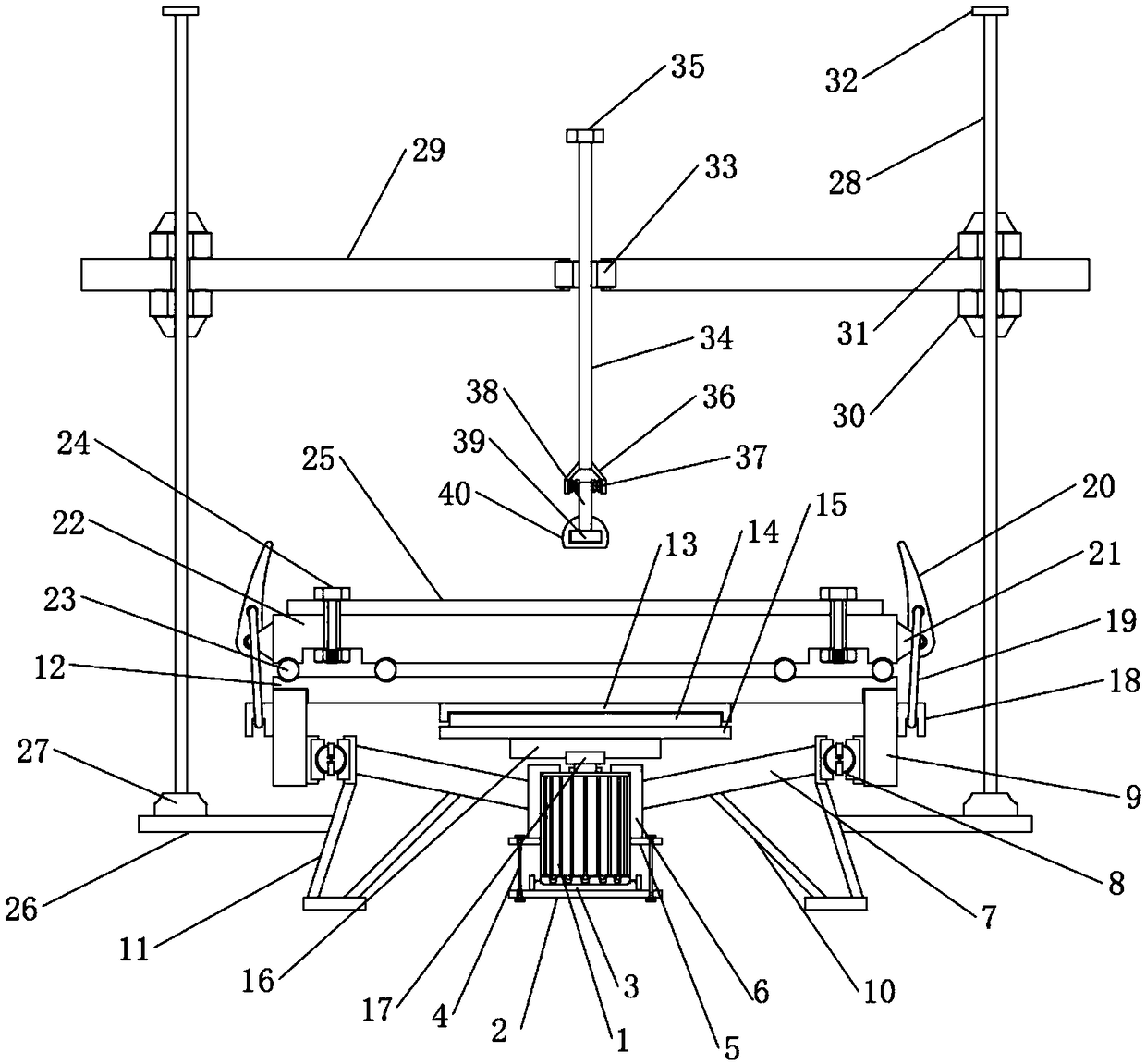

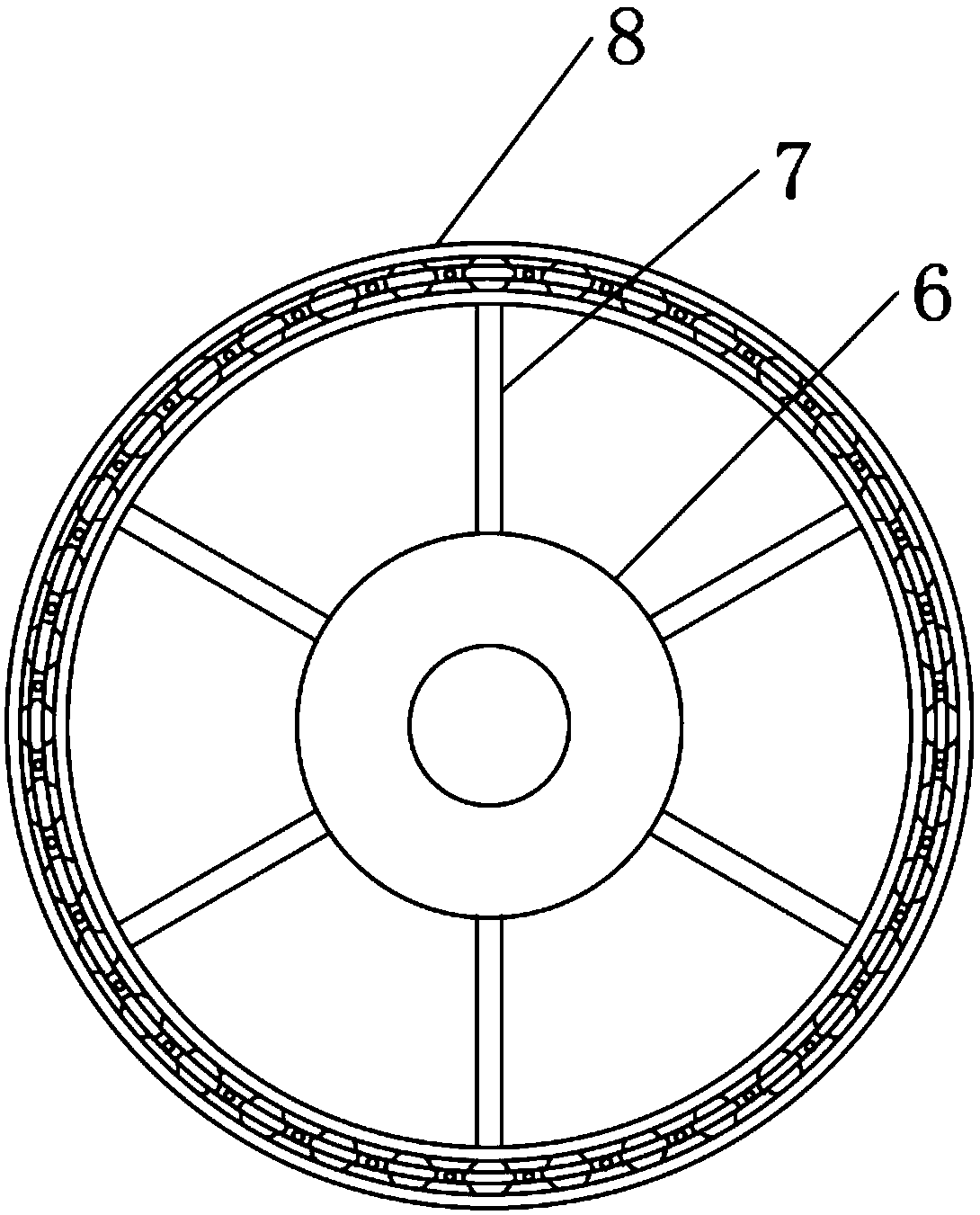

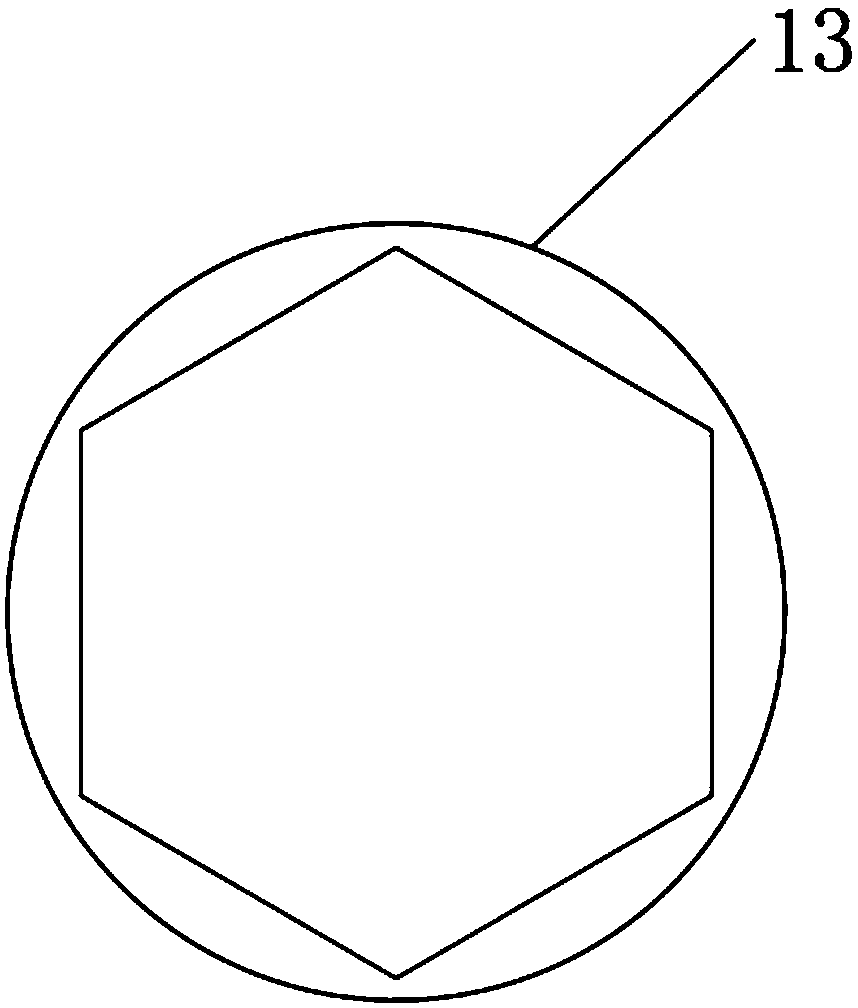

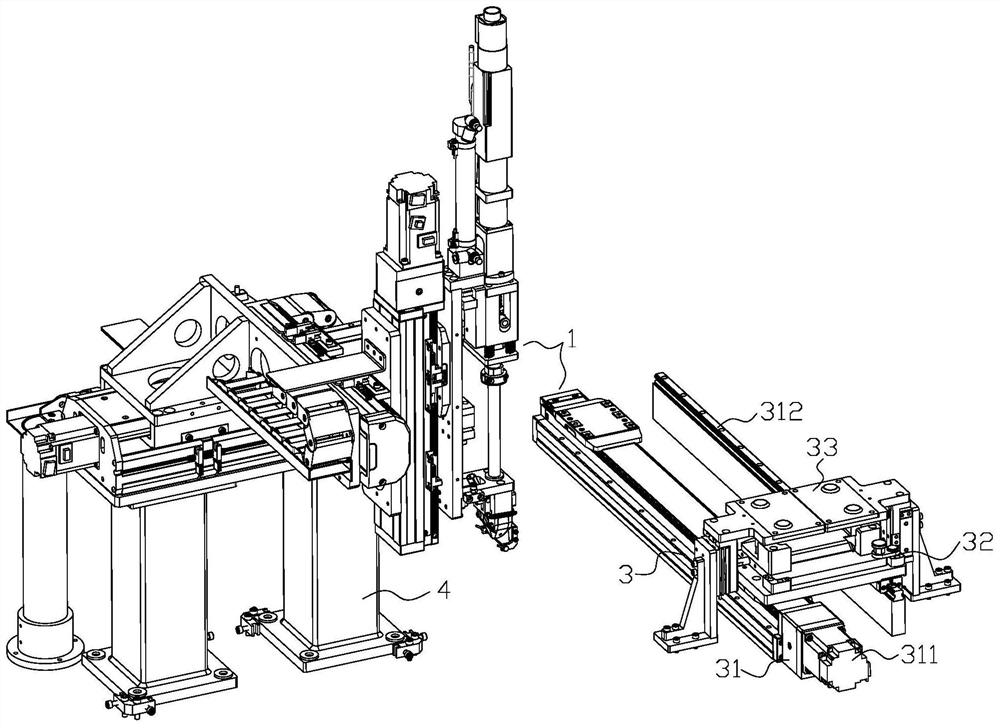

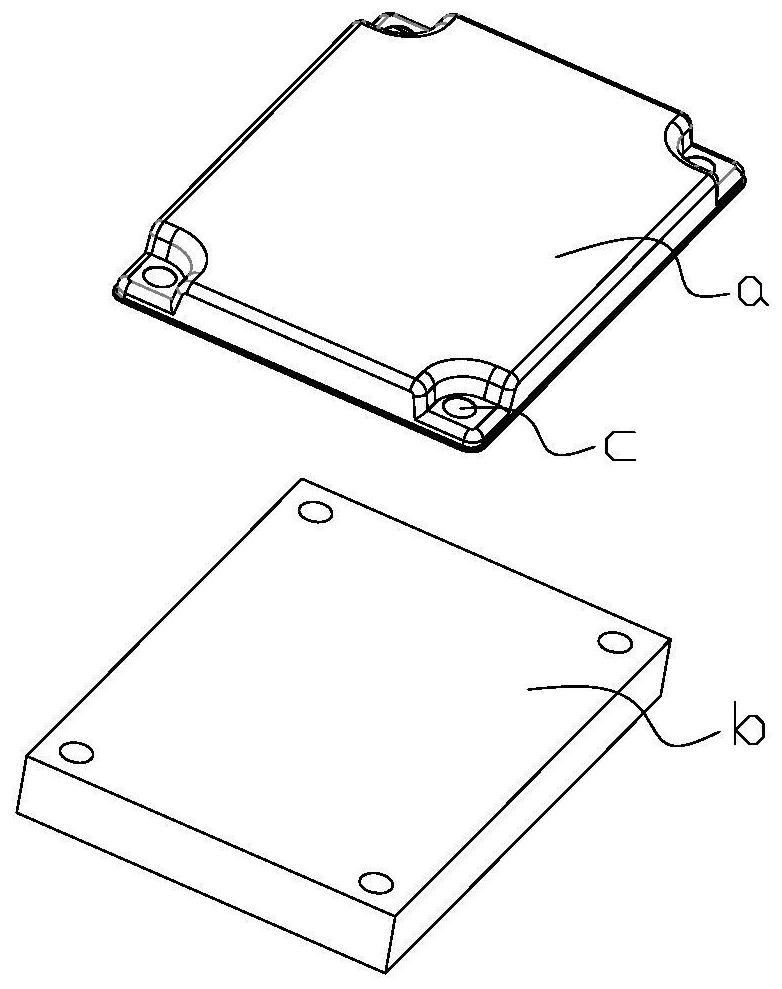

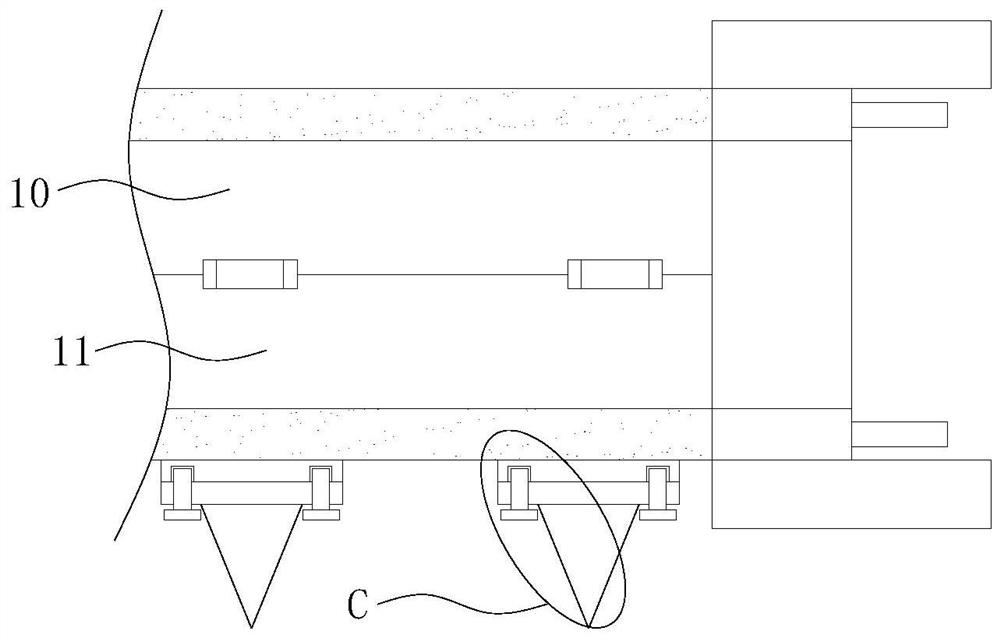

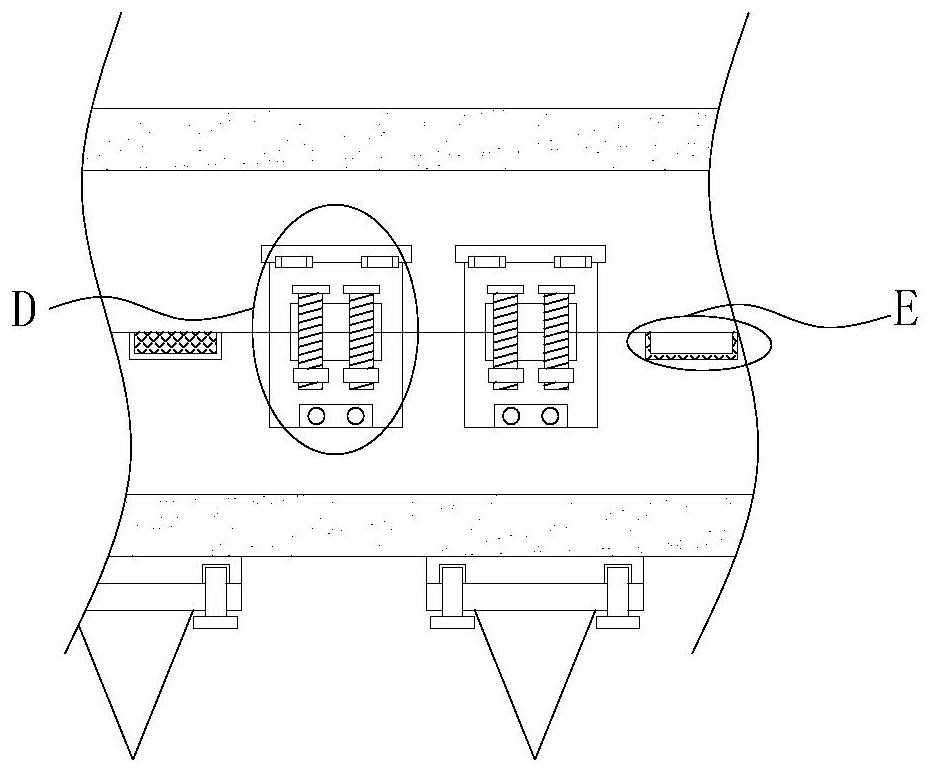

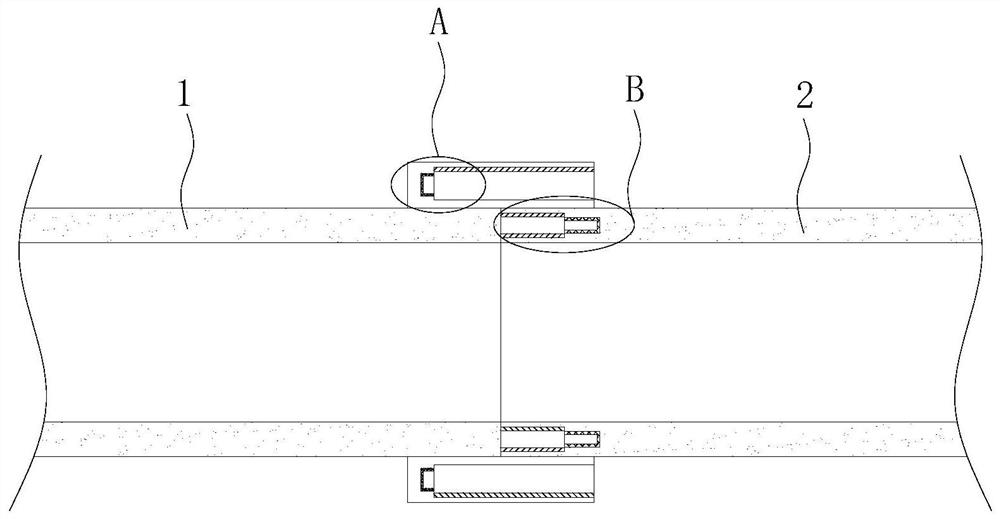

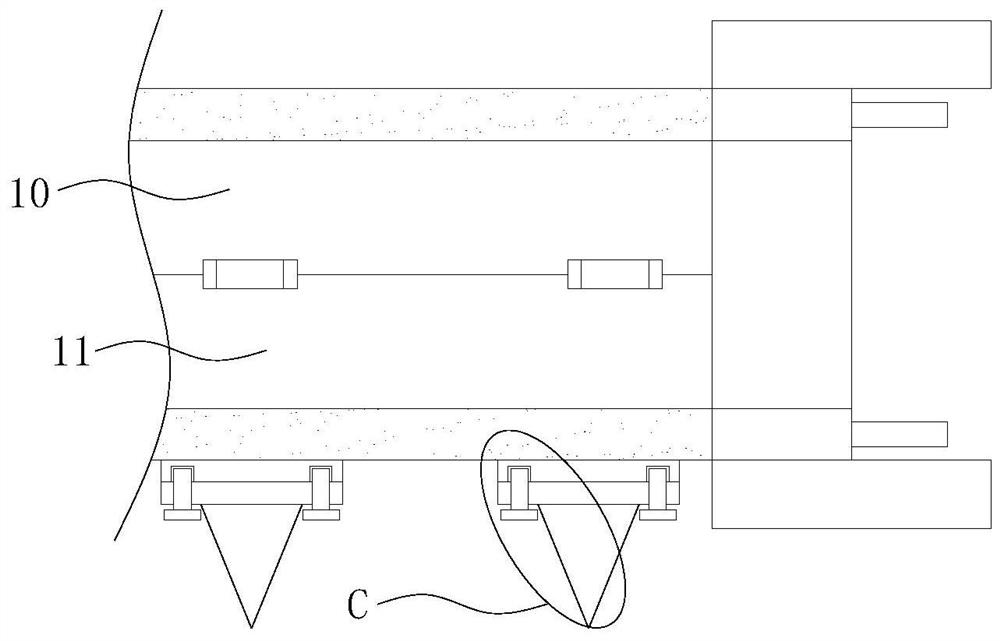

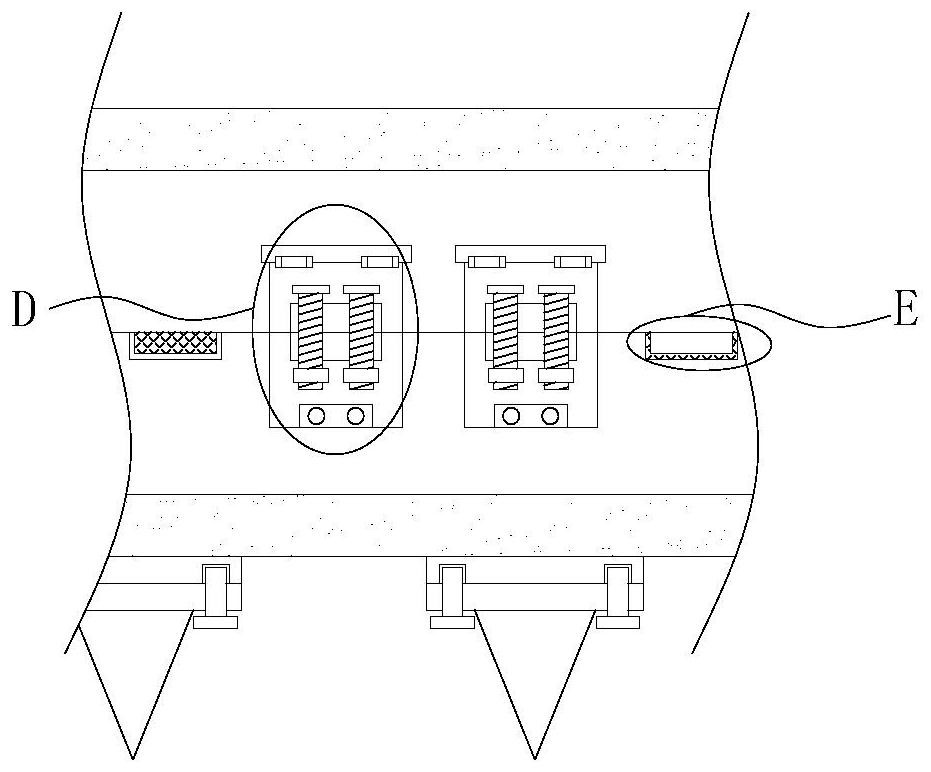

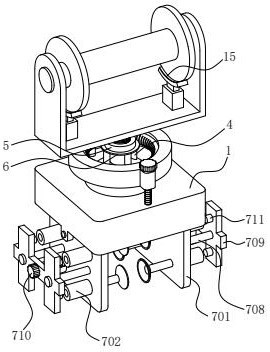

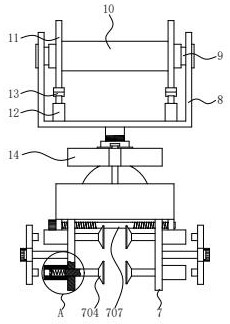

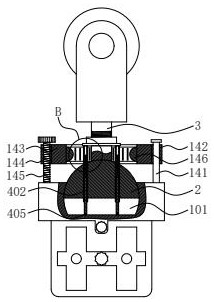

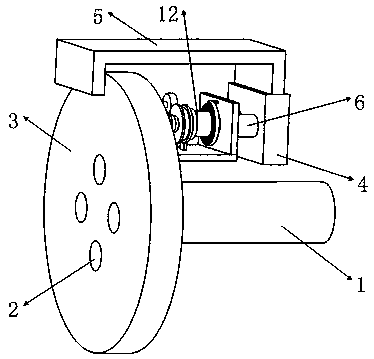

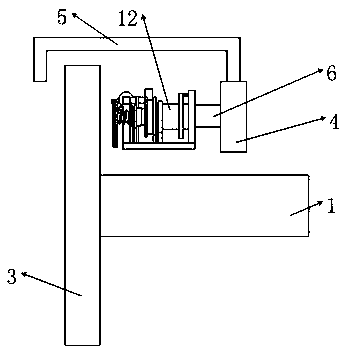

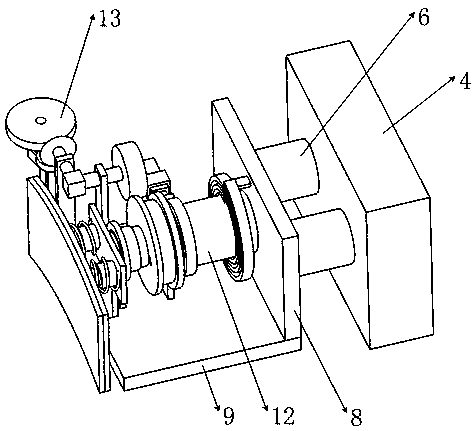

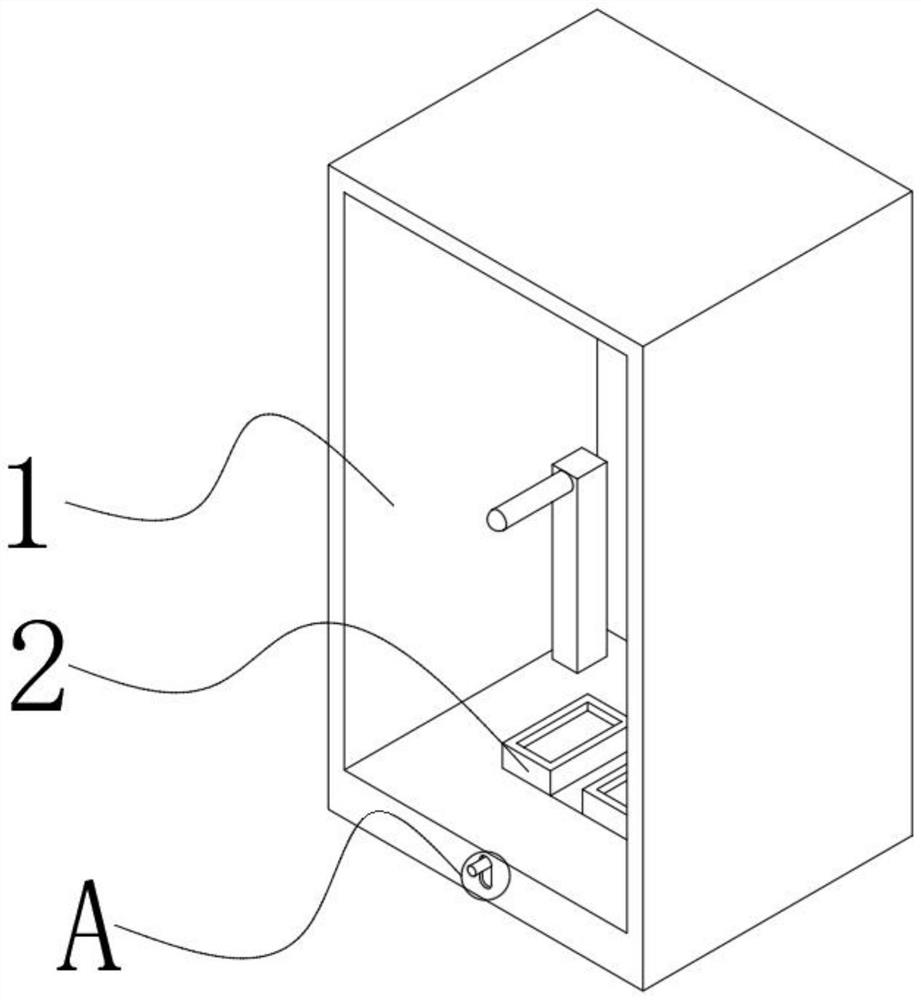

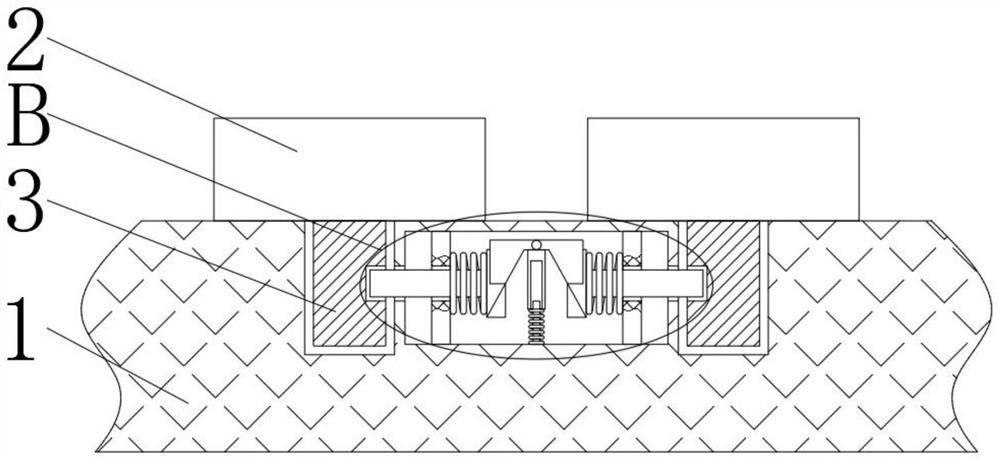

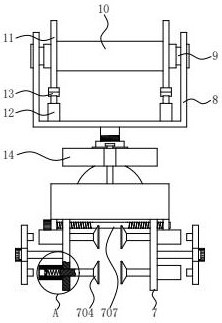

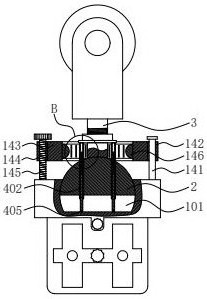

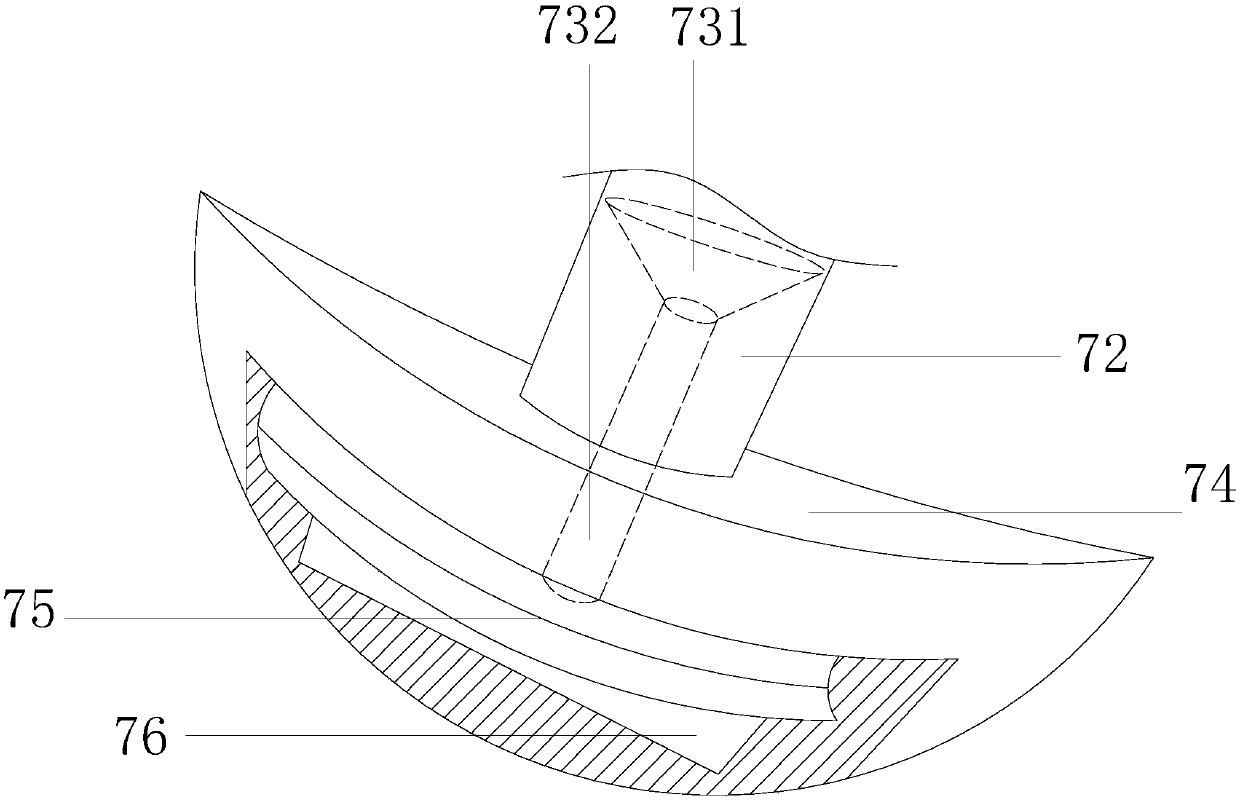

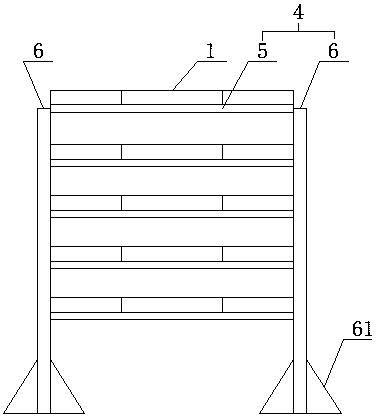

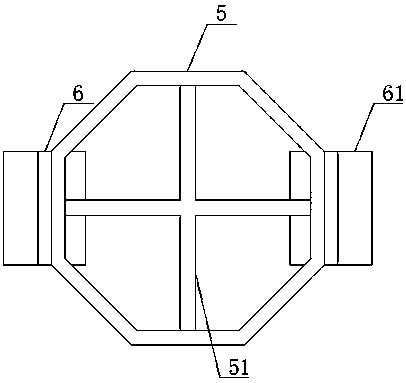

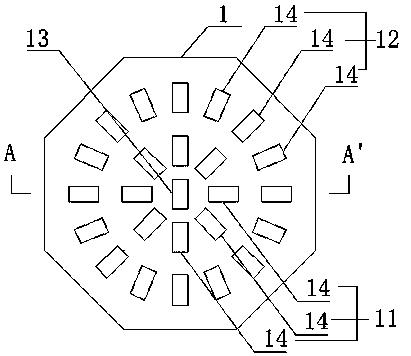

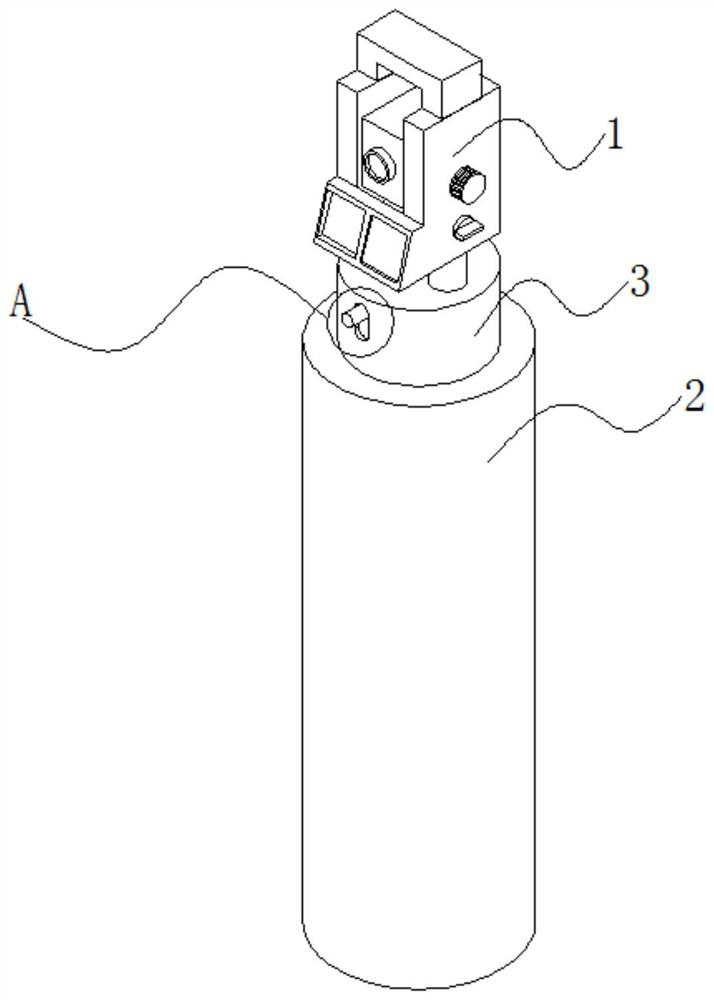

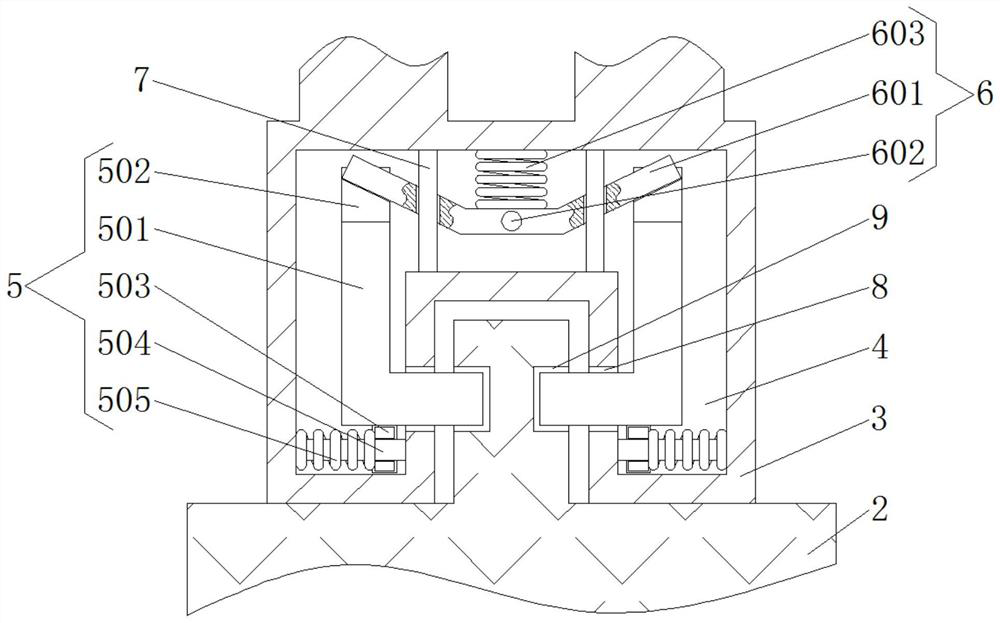

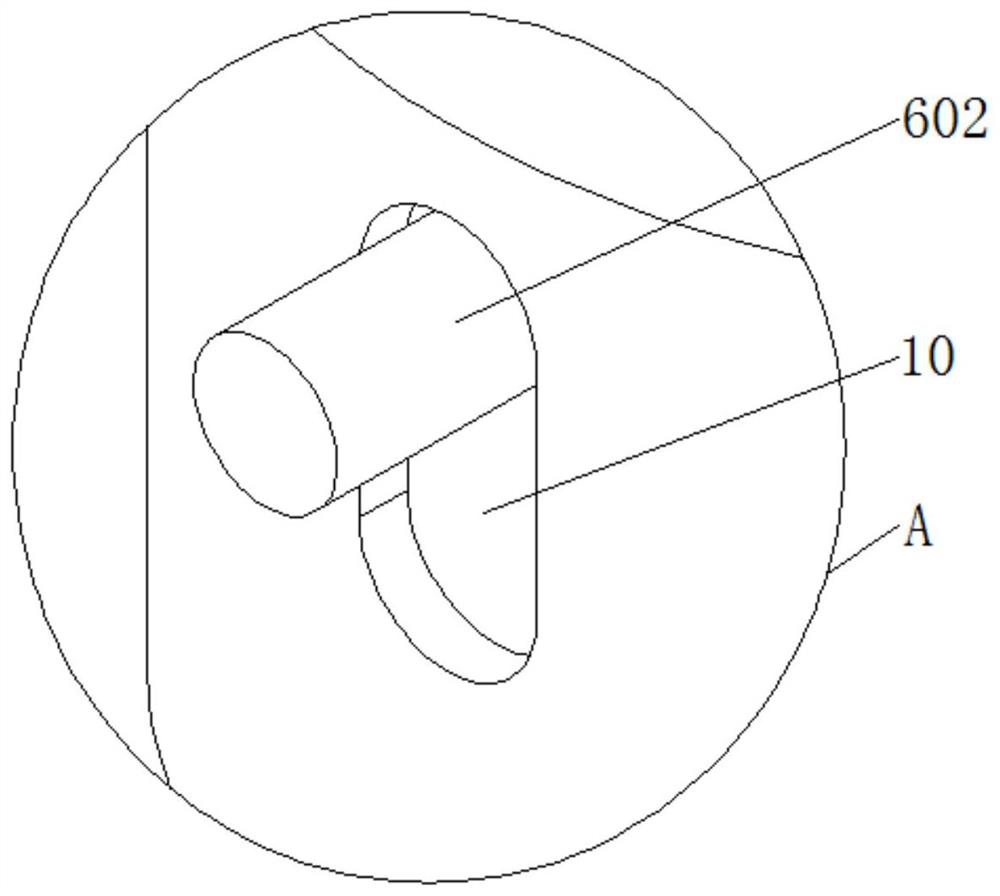

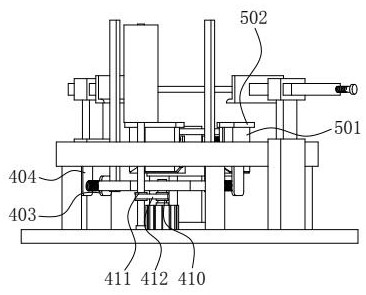

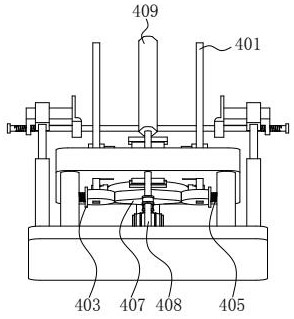

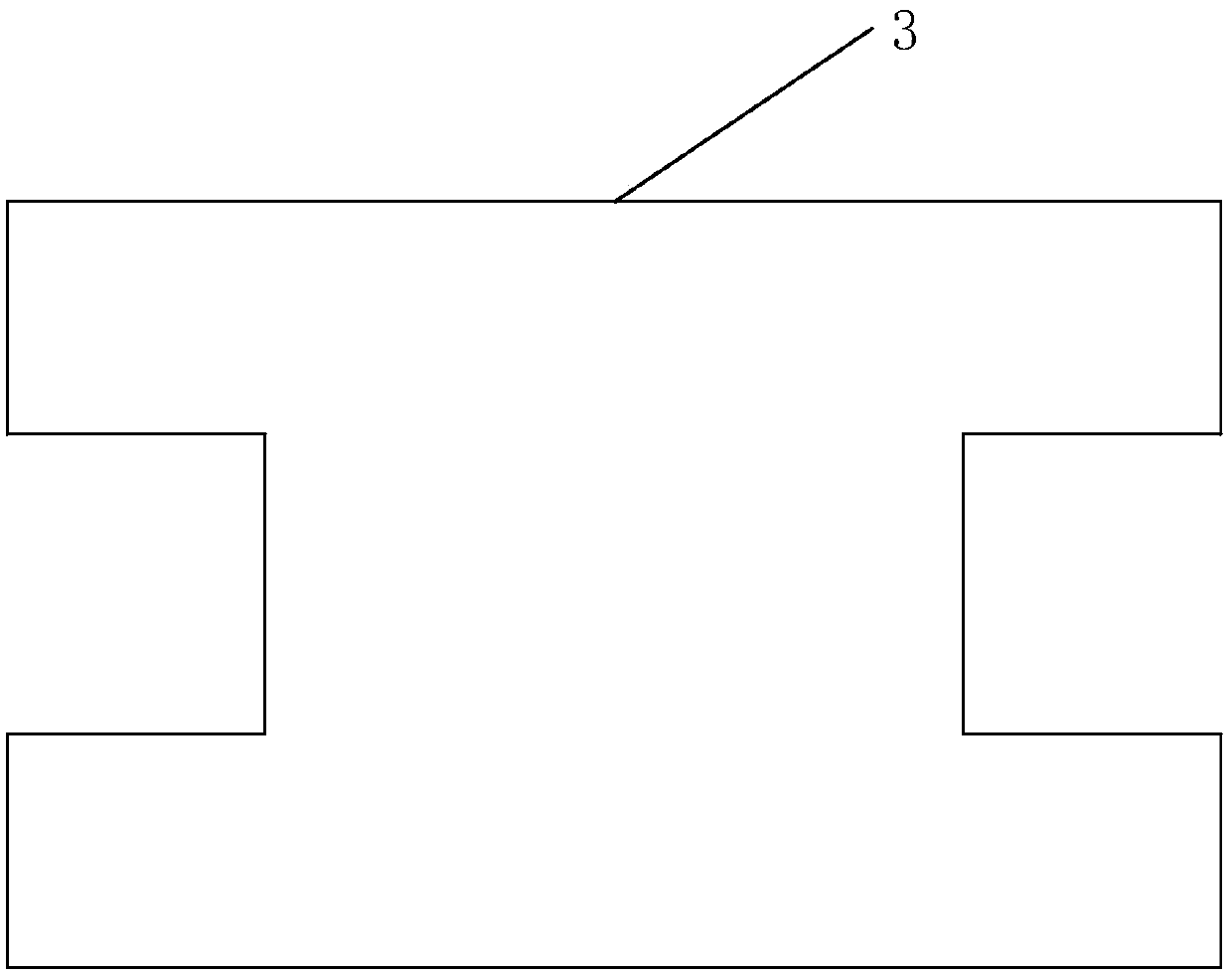

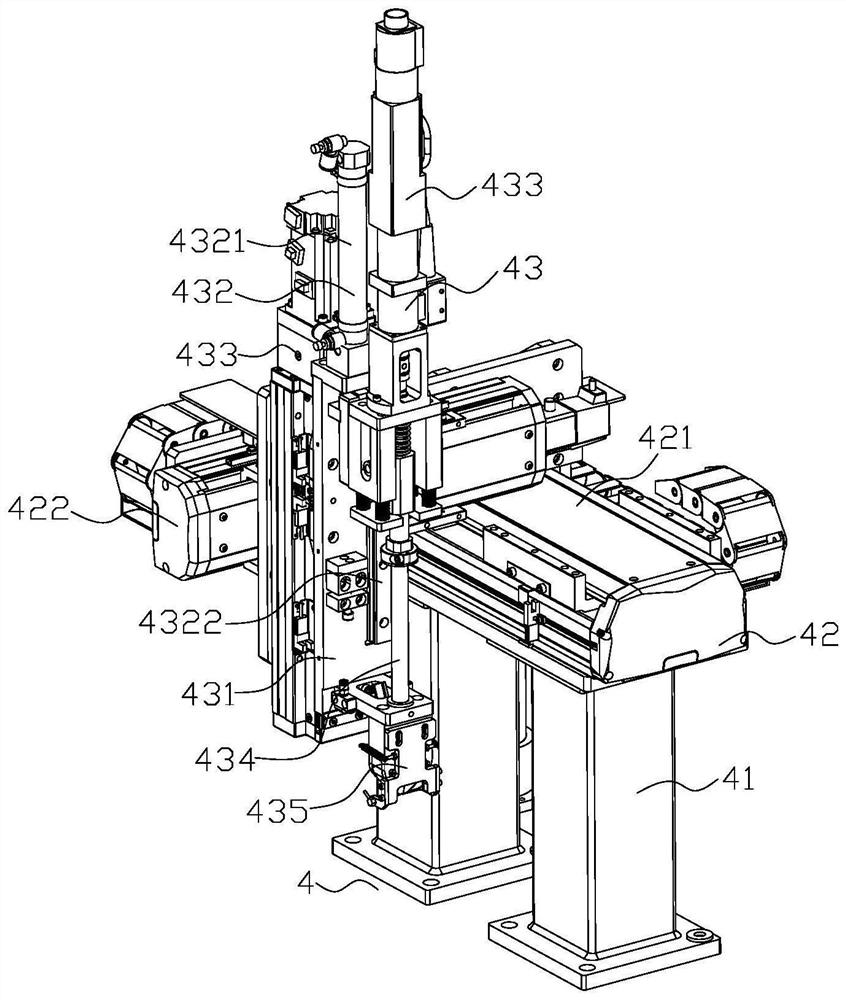

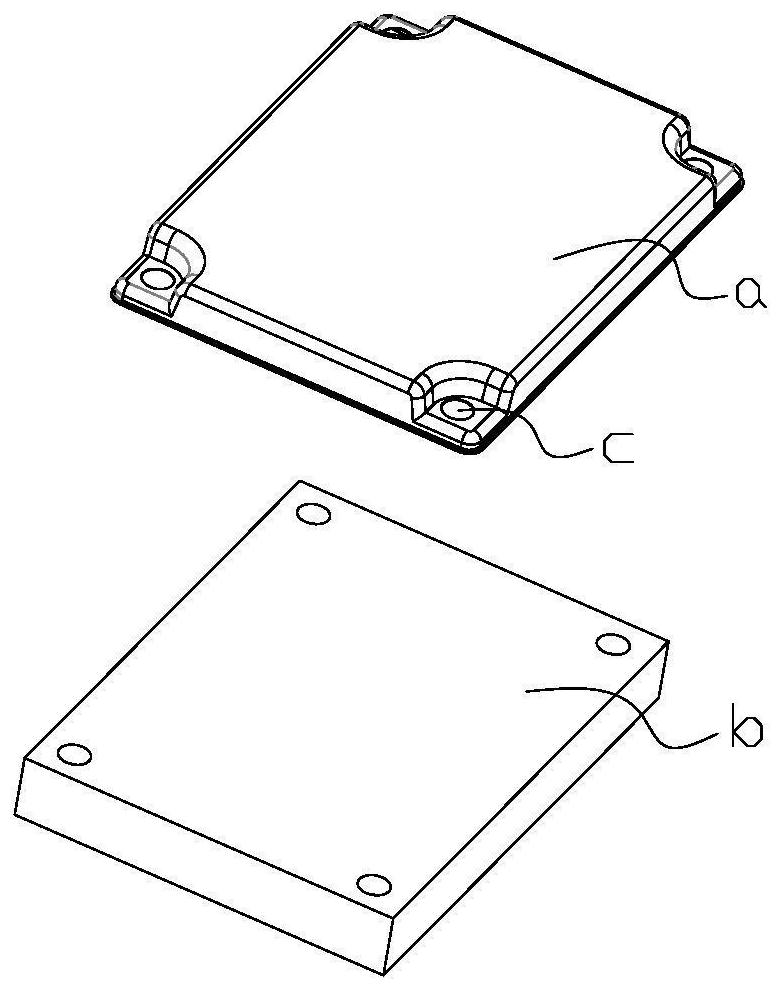

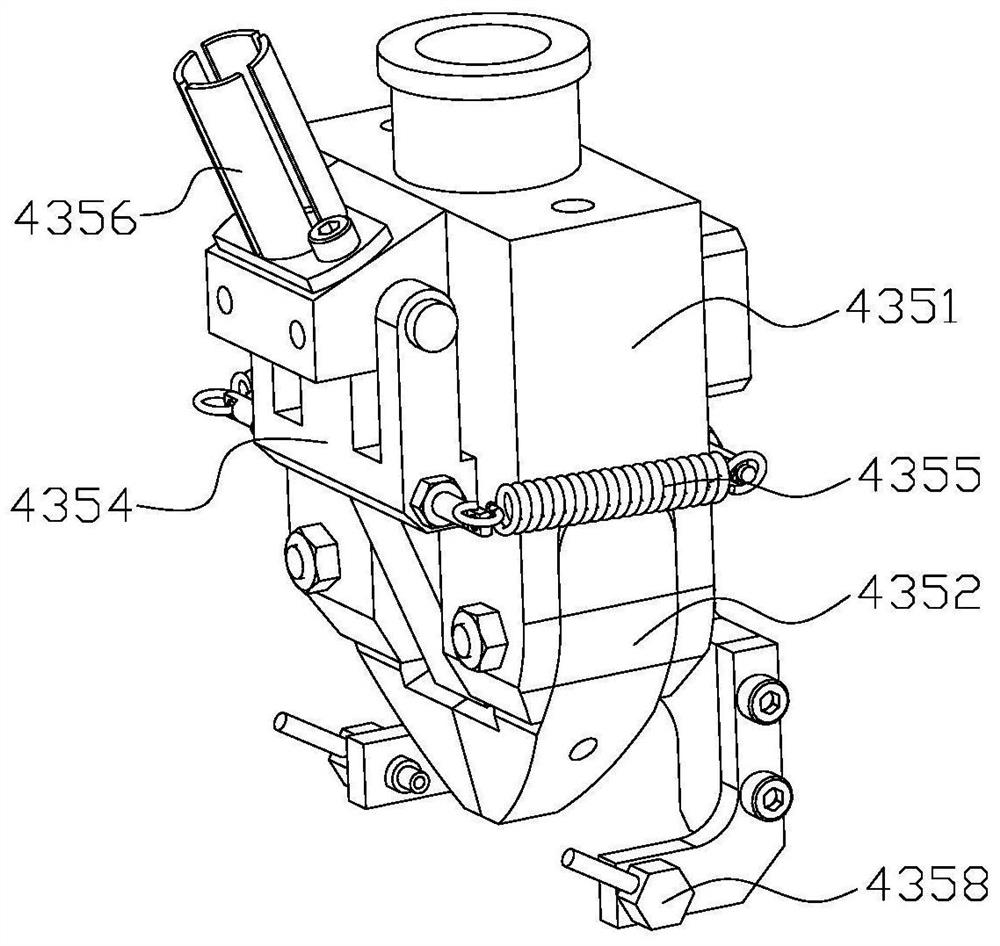

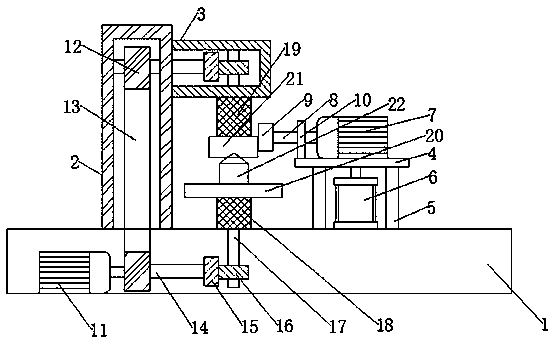

Transformer iron core automatic lamination device

ActiveCN113470965APlay a positioning roleAvoid frictional situationsTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

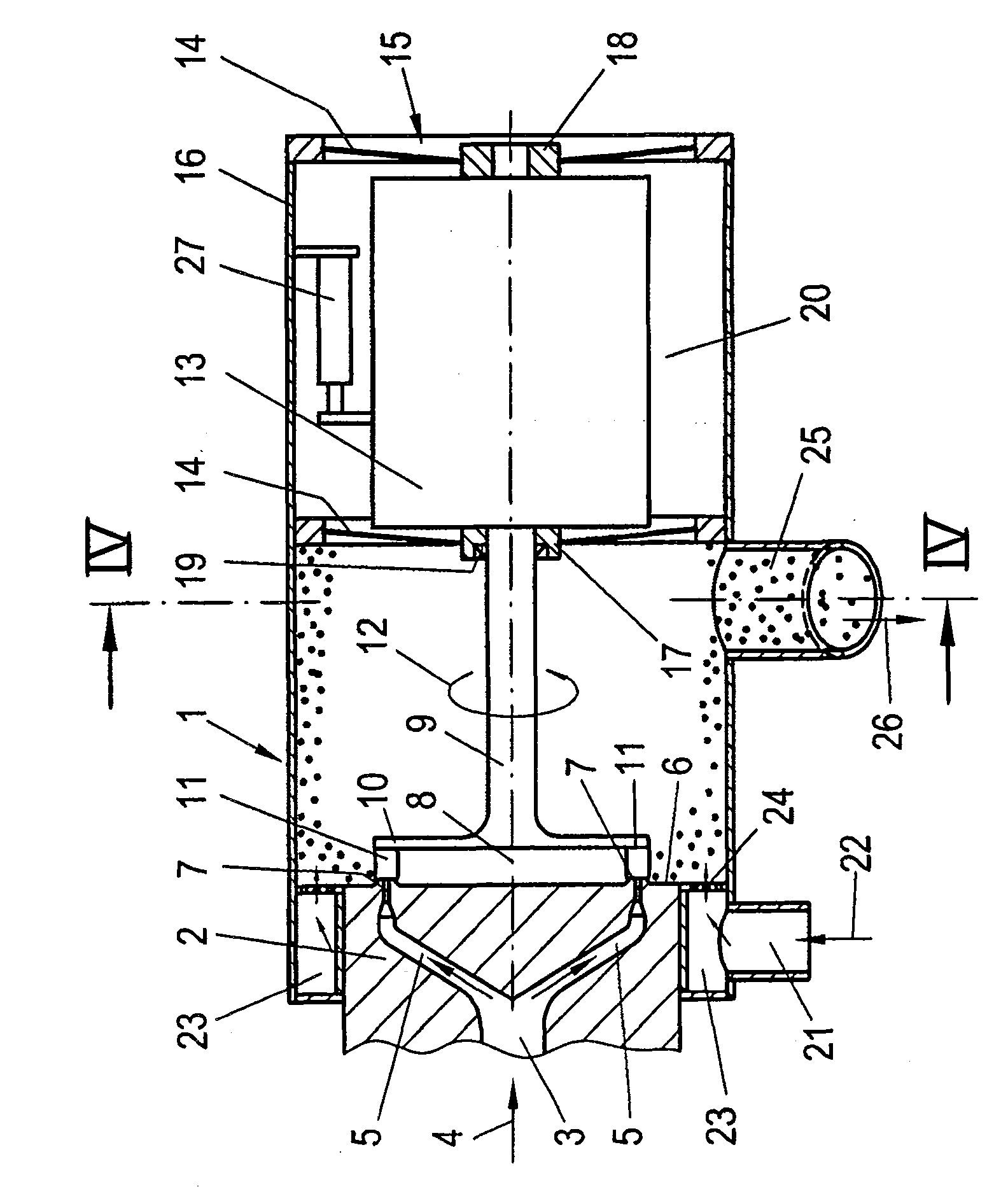

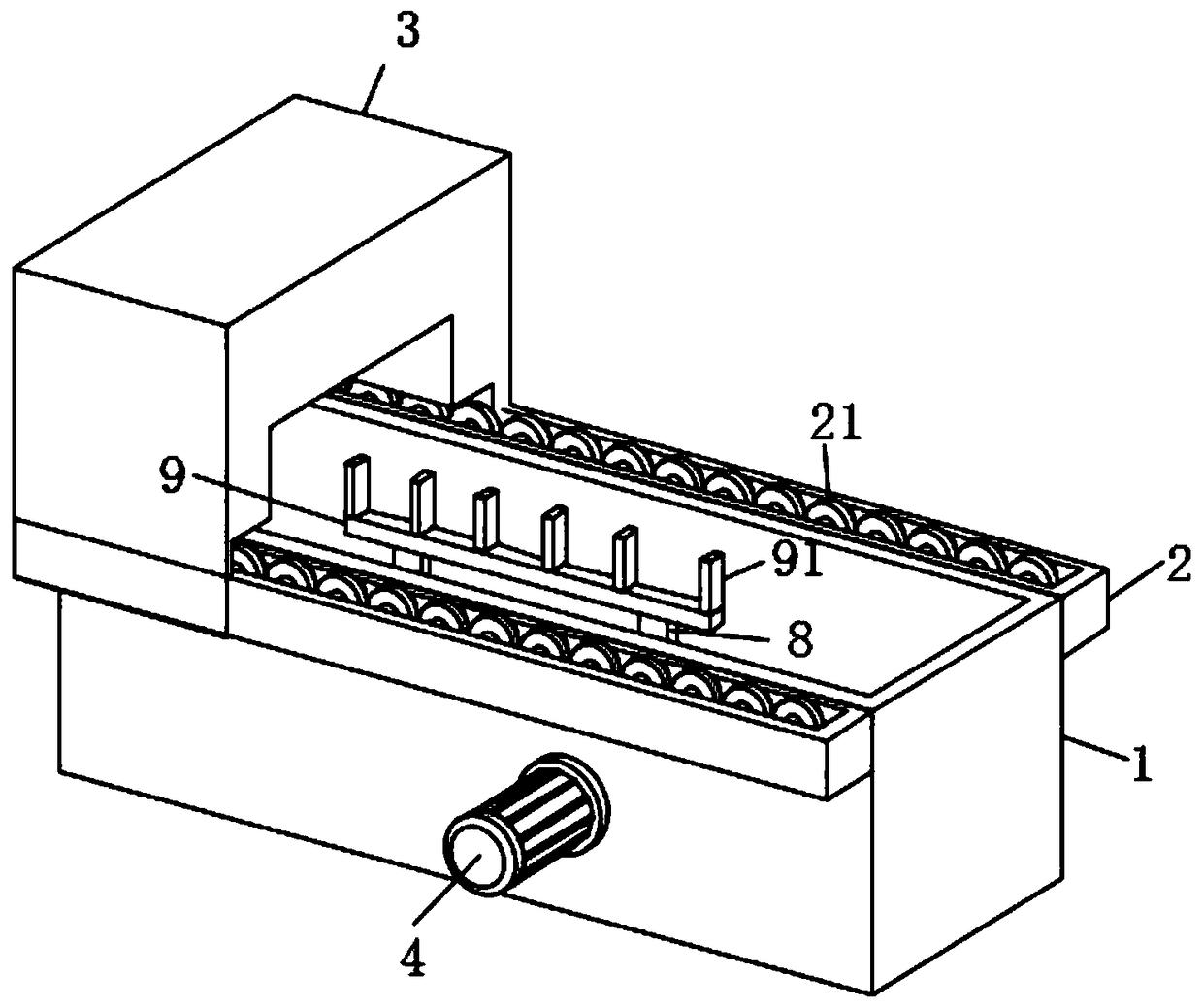

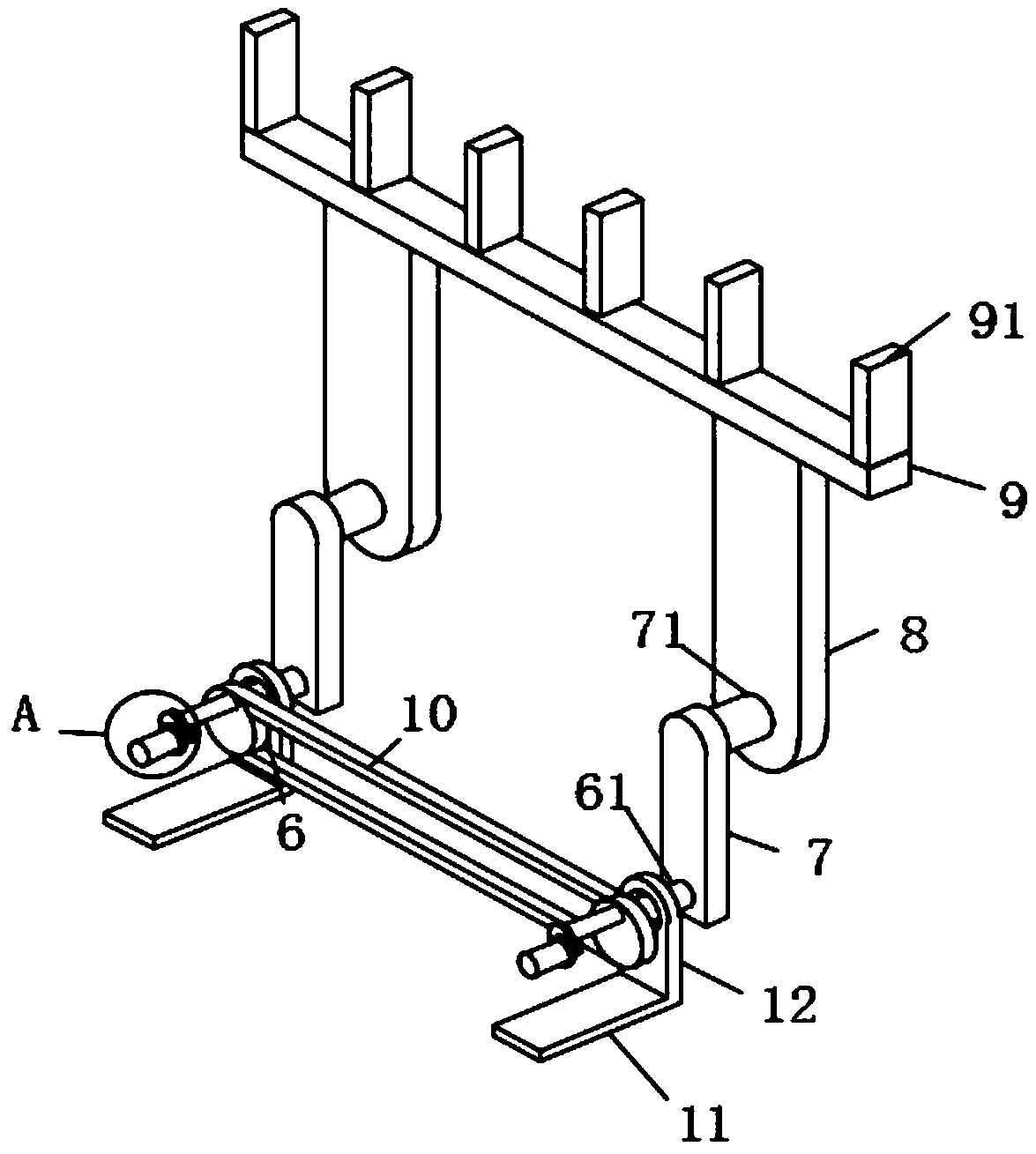

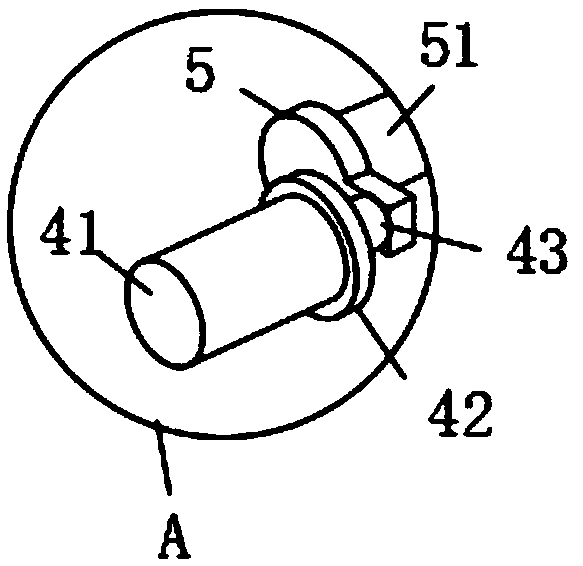

The invention belongs to the technical field of transformer accessory manufacturing, and particularly relates to a transformer iron core automatic lamination device which comprises a horizontal bottom plate, a platform is fixedly installed above the bottom plate through supporting columns, a positioning mechanism and a bearing mechanism are installed above the bottom plate, and a stacking mechanism is installed on the bottom plate; in the process of stacking upper-layer silicon steel sheets on lower-layer silicon steel sheets, the silicon steel sheets do not make contact with vertical rods, and the situation that friction is generated between the edges of the silicon steel sheets and the vertical rods is avoided; in the process of mounting a clamping plate after the silicon steel sheets are stacked into an iron core, the limiting effect on a single wedge-shaped block is sequentially relieved, so that a lifting block and a bearing plate move downwards under the action of self gravity, the bearing plate is separated from the bottom surface of the silicon steel sheet on the lowest layer, and the effect of mounting the clamping plate under the condition that the silicon steel sheets are not lifted is achieved; and the condition that extrusion force and friction force are generated between the silicon steel sheets and the vertical rods is avoided.

Owner:昌航电气有限公司

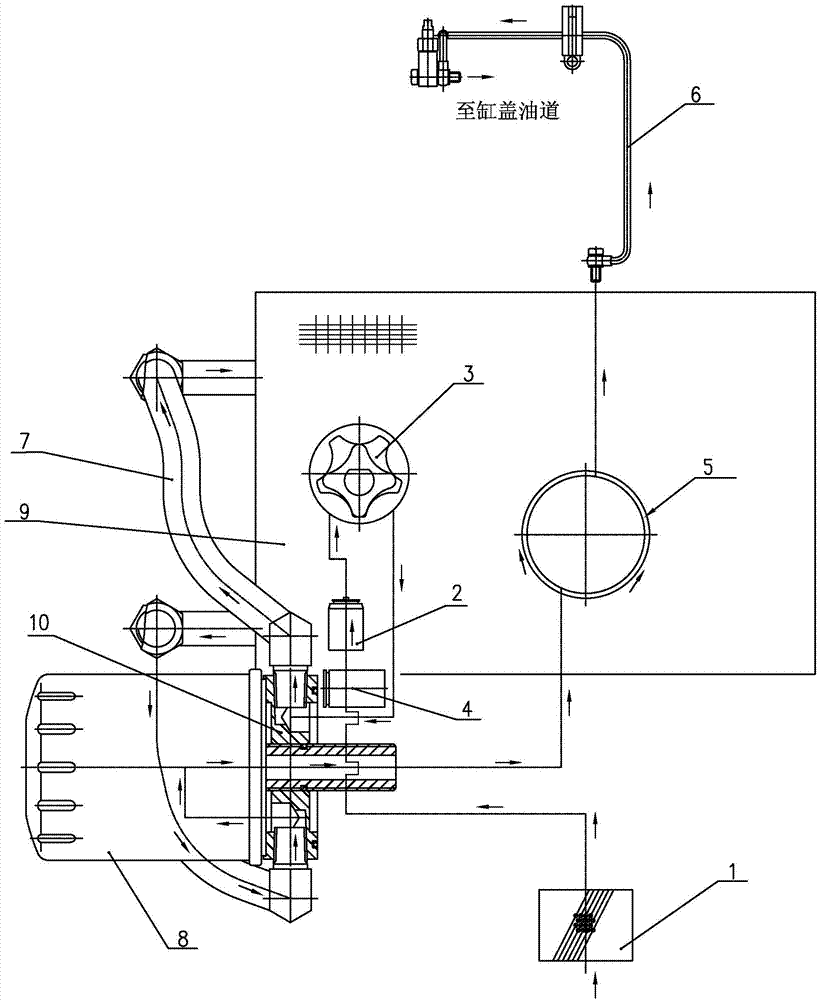

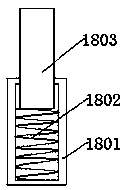

Lubricating oil way which fast pumps oil into lubricating oil channel and is used for diesel engine

ActiveCN104727888AAvoid frictional situationsOpen smoothlyPressure lubrication with lubrication pumpLubricant mounting/connectionInlet channelDiesel engine

The invention relates to a lubricating oil way which fast pumps oil into a lubricating oil channel and is used for a diesel engine. The lubricating oil way comprises an oil pond, a vertical oil inlet channel which is arranged in the engine body of the diesel engine and connected with the oil pond, a one-way valve which is arranged at the bottom of the vertical oil inlet channel and prevents oil in the vertical oil inlet channel from flowing back to the oil pond, and an oil pump communicated with the top of the vertical oil inlet channel; after the oil pump is shut down, the oil is sealed in the vertical oil inlet channel through the one-way valve, and when the oil pump is started again, the oil pump can fast pump the oil to the lubricating oil channel. The difficult problem that oil is fed slowly when an engine is started is solved, and the problems about bearing score, cylinder score and the like are effectively solved.

Owner:CHANGZHOU KOOP POWER MACHINERY

Modern tramcar contact network small tension setting-out method

InactiveCN106882083AAvoid frictional situationsReduce rework rateTrolley linesApparatus for overhead lines/cablesContact networkEngineering

The invention discloses a modern tramcar contact network small tension setting-out method. The method comprises the steps of S1, firstly based on design drawings making work preparation, S2, arranging a tension compensation device A at an anchor section beginning end, S3, using a contact network erection car to weigh anchor at an anchor pillar, and connecting the contact line and the tension compensation device A, S4, in weighing anchor, based on a start tension calculation value, presetting a control tension to set out, S5, during setting-out, making the contact network erection car move slowly to increase the control tension in an average speed, S6, moving the contact network erection car to an anchor falling pillar for anchorage, S7, arranging a tension compensation device B on the anchor falling pillar, S8, connecting the contact network line anchor falling end and the tension compensation device B and setting the tension, and S9, testing the line erection work quality and completing the work. The modern tramcar contact network small tension setting-out method guarantees the tramcar contact network erection quality and duration, and therefore the method is not only suitable for the special lines of tramcars, but also can satisfy the setting-out erection tension of contact network lines.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG

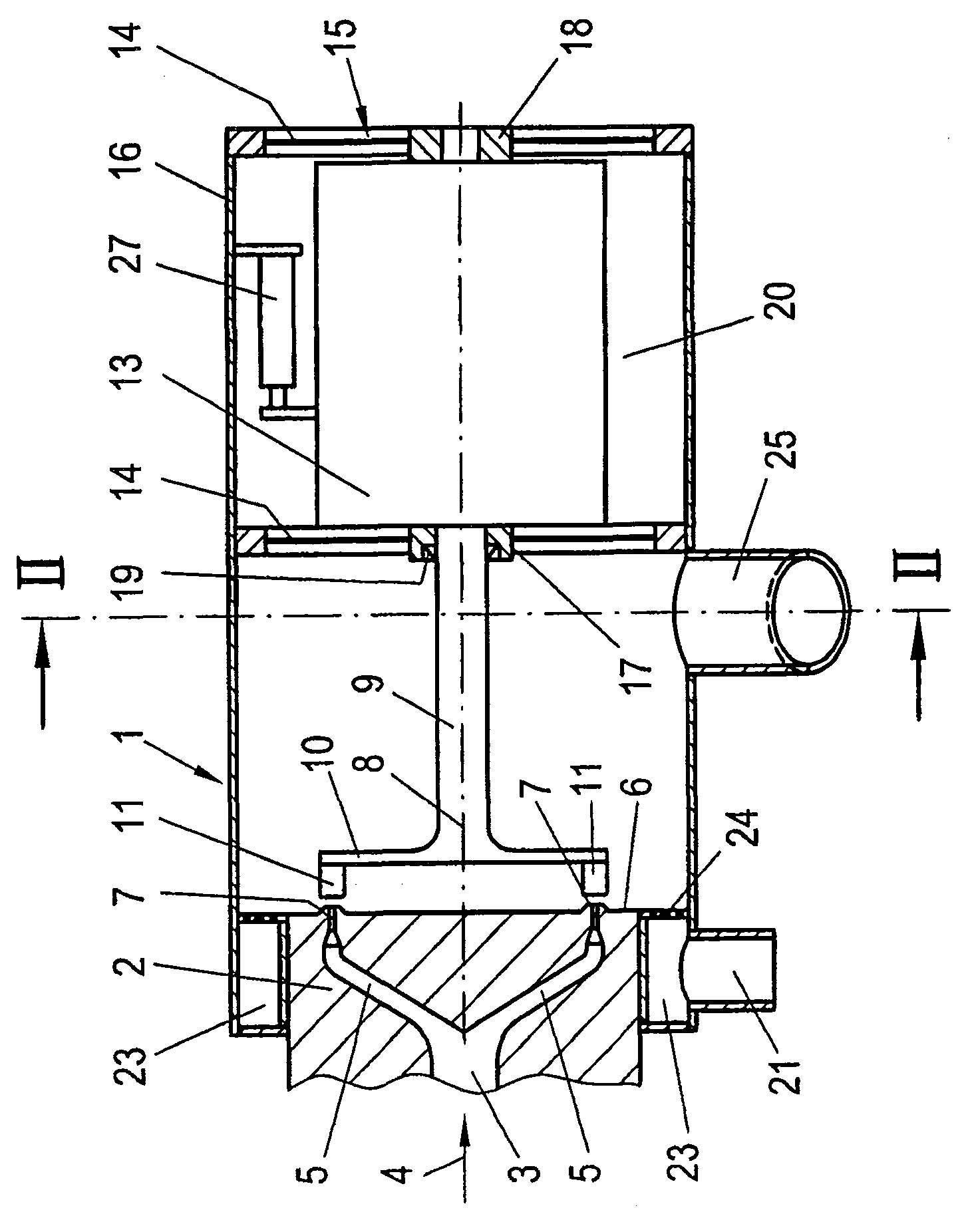

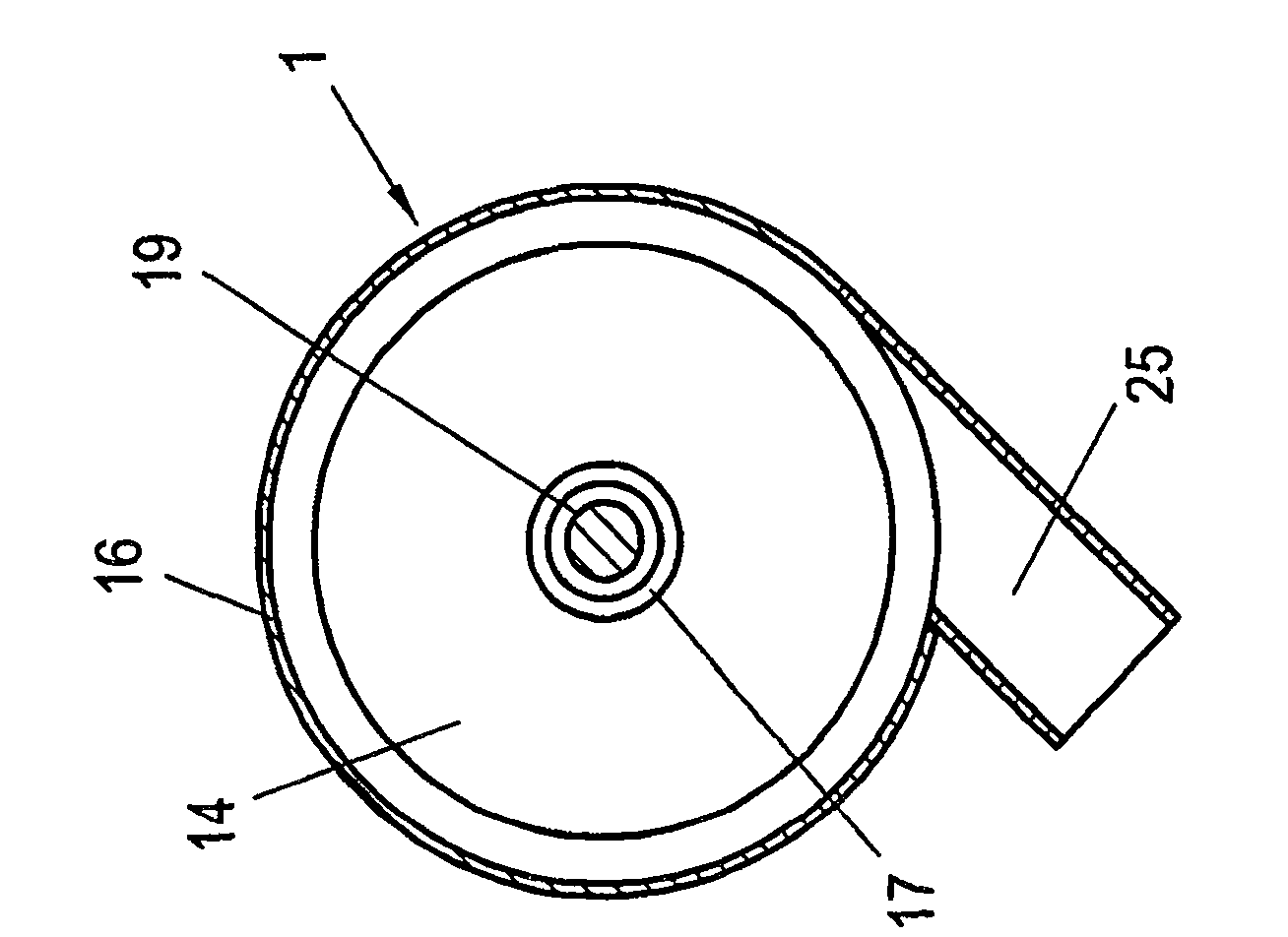

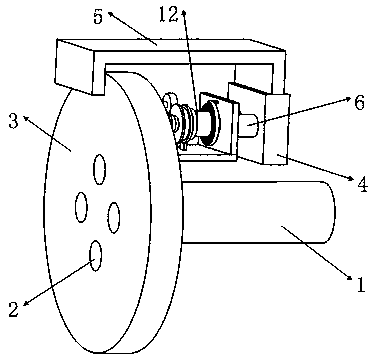

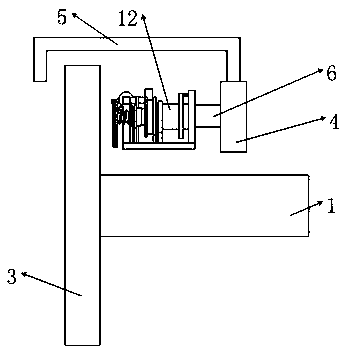

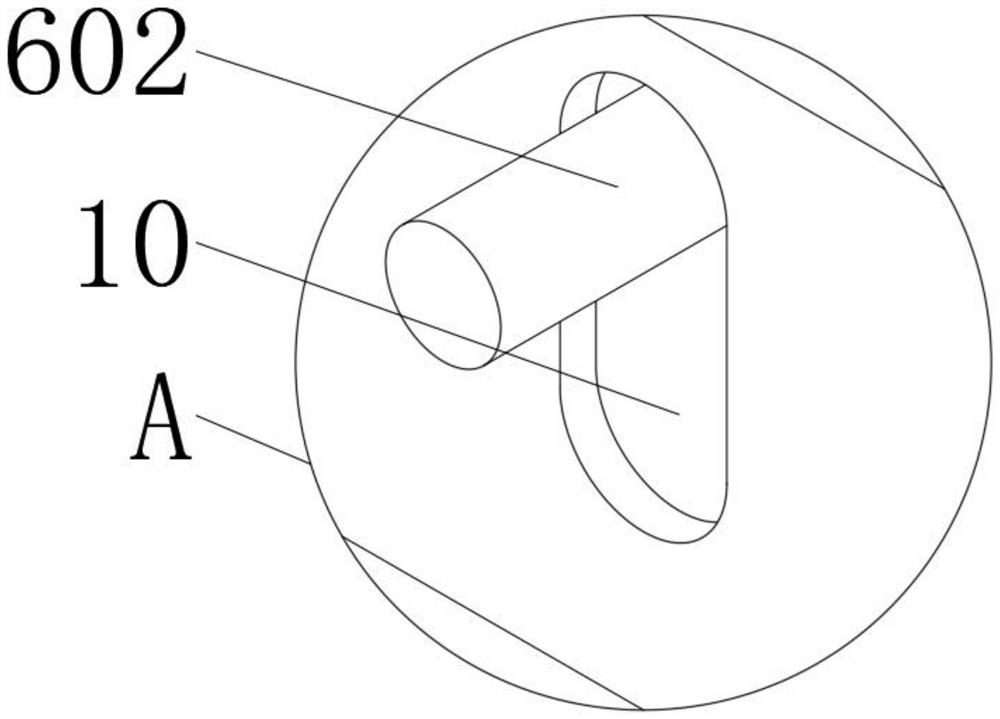

Granulating device

ActiveCN100563975CKnockdown effect is not affectedAvoid frictional situationsGranulation by material expressionMechanical energy handlingThermoplasticEngineering

The invention relates to a device for granulation of an ejected material from at least one nozzle (7), in particular a thermoplastic plastic, with a perforated plate (2) comprising the nozzles (7). A blade head (10) supporting several blades (11) lies opposite the same, fixed to a shaft (9) which is rotatably driven by a motor (13). The motor (13) is suspended such as to be displaced relative to the housing (1) by means of a suspension (15), however the above is suspended in such a manner that displacement is only possible in the direction of the axis (8) of the shaft (9) and not in a radial direction. The suspension (15) comprises at least one membrane (14) which suspends the motor (13) on the granulator housing (1). The motor (13) can be adjusted relative to the perforated plate (2) by means of an adjuster device (27), such that the desired pressure of the blade on the perforated plate (2) is maintained. The excised granulate particles are drawn out of the housing (1) by means of coolant.

Owner:EREMA ENG RECYCLING MASCH & ANLAGEN GMBH

Plate surface paint drying device

InactiveCN109225777AEasy to moveAvoid frictional situationsPretreated surfacesCharge manipulationFixed frameEngineering

The invention discloses a plate surface paint drying device. The device comprises a conveying frame, a drying fan and fixing plates, the drying fan is fixedly arranged on one side of the upper end ofthe conveying frame, and fixing frames are symmetrically welded at the upper end of the conveying frame; an inner groove is formed in each fixing frame, and plates are sequentially arranged on the upper surface of a conveying wheel at equal intervals so that the plates can move forwards stably, and friction caused when the plates are attached to the surface of the conveying frame is avoided; an inserting rod performs circular motion in an inserting groove of a limiting plate so as to drive a rotating plate to rotate, and finally the fixing plates are driven to move up and down, so that the plates are clamped by adjacent partition plates and conveyed forwards; a driving motor drives one second rotating disc to rotate, and the second rotating disc can drive the other second rotating disc torotate through a belt so that the adjacent fixing plates can move up and down to drive a lifting rod to move.

Owner:合肥市瑞丽宜家家居有限公司

Hot air non-woven setting machine with paired held net curtain automatic correction function

ActiveCN106012301AAvoid frictional situationsHeating/cooling textile fabricsNon-woven fabricsPulp and paper industry

A hot air non-woven setting machine with a paired held net curtain automatic correction function comprises a machine frame, an upper held net curtain driving mechanism, a lower held net curtain driving mechanism, upper hot air boxes, lower hot air boxes, an upper hot air box lifting adjusting mechanism, an upper held net curtain and a lower held net curtain, wherein the upper held net curtain driving mechanism and the lower held net curtain driving mechanism correspond to the right side of the machine frame and are connected with the machine frame; the upper hot air boxes and the lower hot air boxes are arranged along the upper portion and the lower portion of the length direction of the machine frame from left to right; the upper hot air box lifting adjusting mechanism is arranged on the upper portion of the machine frame and connected with the upper hot air boxes. The setting machine is characterized by further comprising an upper held net curtain correction mechanism and a lower held net curtain correction mechanism, the upper held net curtain correction mechanism corresponds to the left side of the machine frame and is connected with the machine frame, the lower held net curtain correction mechanism corresponds to the lower portion of the upper held net curtain correction mechanism and is connected with the left side of the machine frame, one end of the upper held net curtain is arranged on the upper held net curtain correction mechanism in a sleeving mode, the other end of the upper held net curtain is arranged on the upper held net curtain driving mechanism in a sleeving mode, one end of the lower held net curtain is arranged on the lower held net curtain correction mechanism in a sleeving mode, and the other end of the lower held net curtain is arranged on the lower held net curtain driving mechanism in a sleeving mode. Friction, caused by deflection of the upper held net curtain and the lower held net curtain, of the setting machine and a wallboard is avoided.

Owner:苏州圣菲尔新材料科技有限公司

Scroll compressor and air conditioner with same

PendingCN108050068AImprove stability and reliabilityAvoid frictional situationsRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention provides a scroll compressor and an air conditioner with the same. The scroll compressor comprises a movable disc and a static disc; the movable disc is engaged with the static disc to form compression cavities; multiple compression cavities are provided, and comprise first compression cavities and second compression cavities; the static disc is provided with a first preset area anda second preset area; the first preset area and the second preset area are relatively arranged about a geometric center of the static disc; the first preset area is used for forming the first compression cavities; the second preset area is used for forming the second compression cavities; the static disc is provided with a conducting structure; and when the first compression cavities compress to reach a preset angle, and the second compression cavities are located within a preset time after air suction is finished, the first compression cavities and the second compression cavities communicatethrough the conducting structure, so that the pressure of the first compression cavities and the pressure of the second compression cavities are balanced. The compressor with the structure can effectively balance the pressure in the relative compression cavities, and improves the stability and the reliability.

Owner:ZHUHAI LANDA COMPRESSOR +1

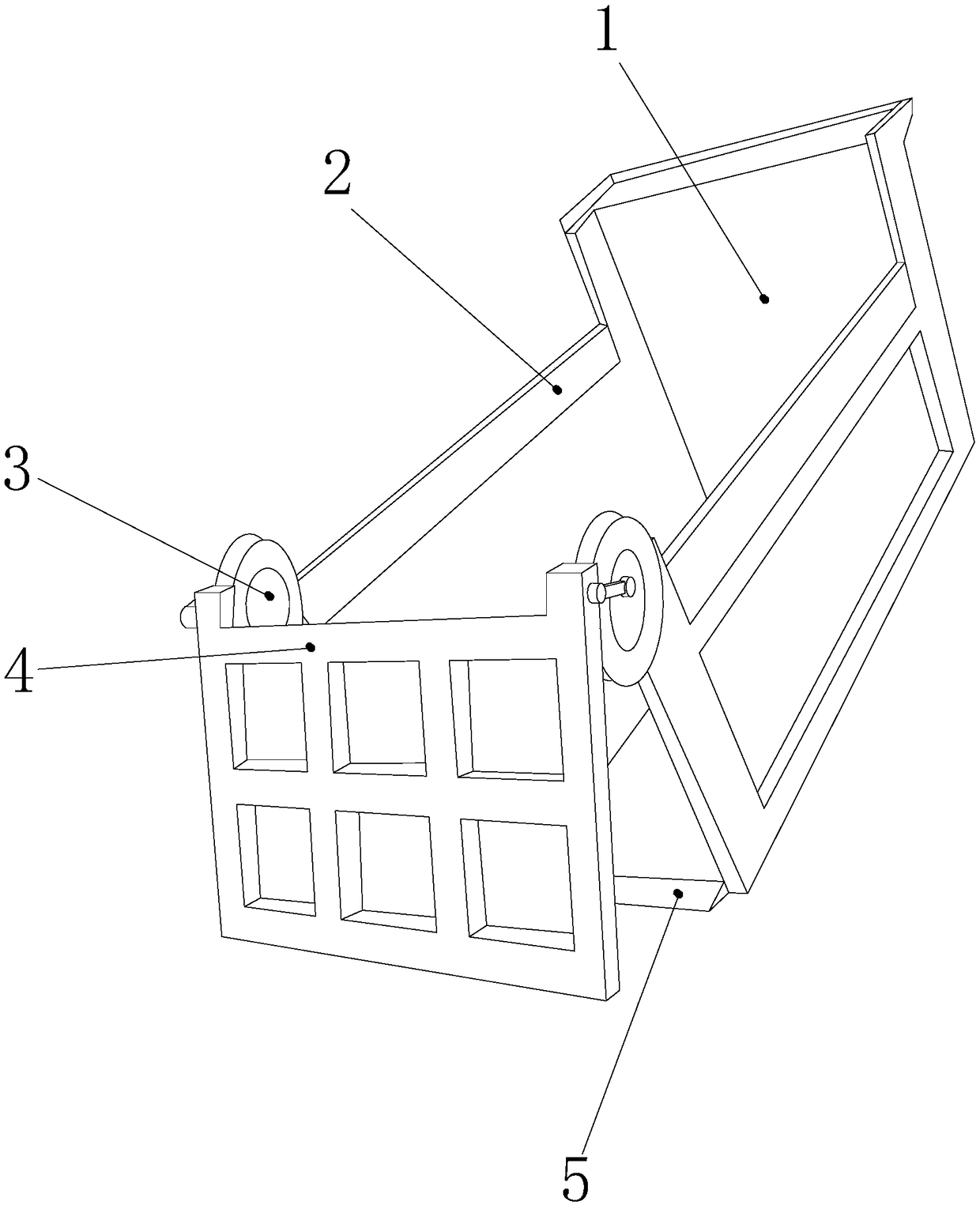

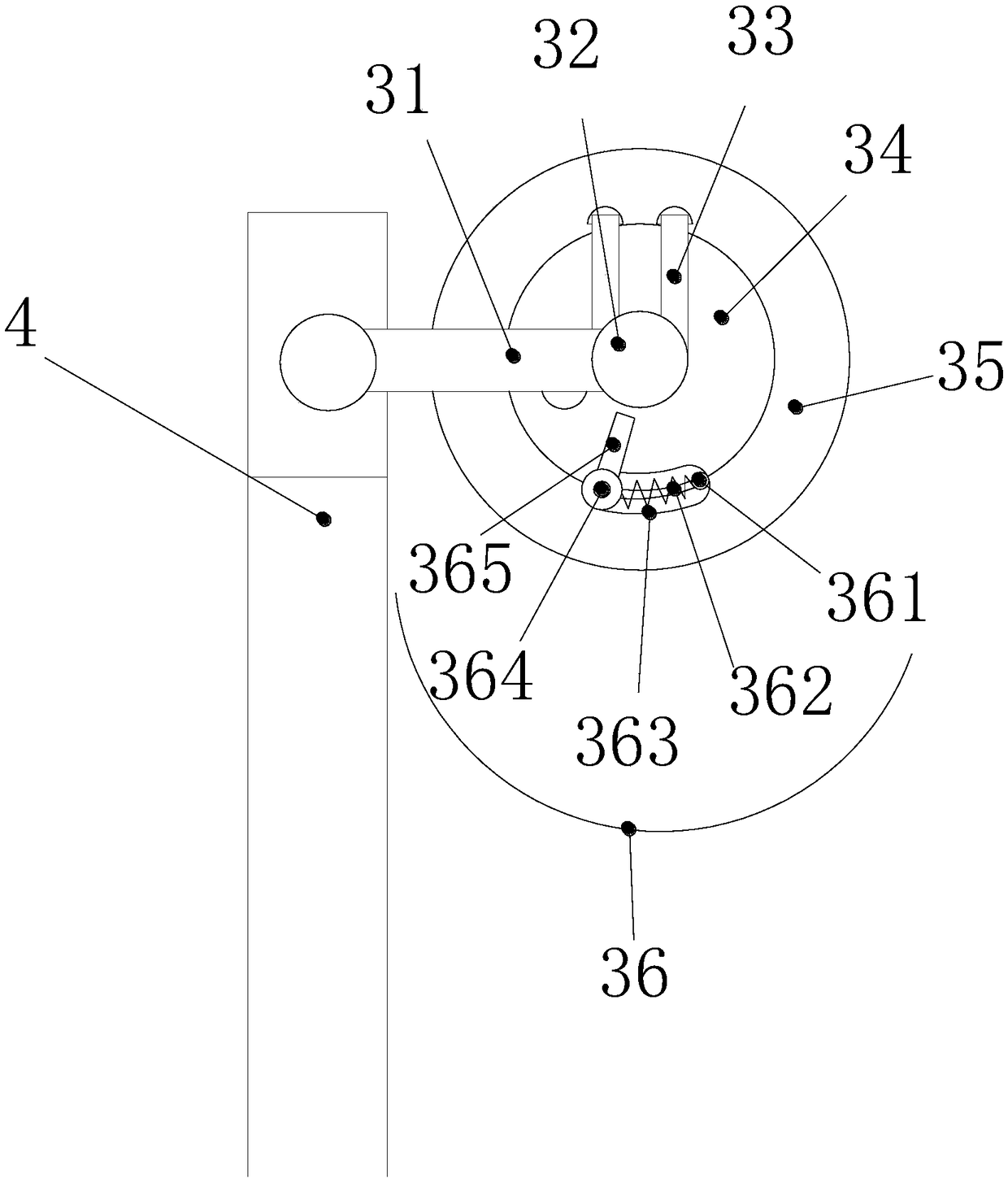

A safety protection device for the angular torque protection a material groove edge of a material unloading door of a sand transport truck

InactiveCN109050374AEasy resetAchieve the effect of protecting the sealing edgeVehicle with tipping movementTruckPulley

The invention discloses a safety protection device for the angular torque protection groove edge of a material unloading door of a sand transport truck, Its structure includes: loading and unloading groove, Edge-sealing baffle, hanger spindle disk, door panel, A load and unloading groove is mechanically connected with that door panel through a hanger rotate shaft plate, two edge sealing baffles are respectively inserted and fitted on the top of the left and right sides of the loading and unloading grooves, the inclined panel is horizontally welded at the bottom of the front side of the loadingand unloading groove, the hanger rotating shaft plate is provided with two and is respectively arranged at the upper left corner and the upper right corner of the front side of the loading and unloading groove, A suspension frame rotate shaft plate is matched with a door plate, the loading and unloading groove lifts and opens the door panel to unload the sand grains, The self-weight of the door plate flips and fits on the left side of the loading and unloading groove along the truss rod and the sleeve cap, and the truss rod rotates and pushes the sliding mechanism to limit the sliding angle between the pulley and the spring elbow pipe, thus avoiding the friction with the chamfer of the loading and unloading groove when the door plate is reset, and achieving the effect of angular torque protection and sealing edge.

Owner:张涛

High-security-performance ultraviolet curing machine for flexible manufacturing production line of receivers

PendingCN107809727AImprove efficiencyImprove the use effectElectrical transducersMotor shaftWork in process

The invention relates to a high-security-performance ultraviolet curing machine for a flexible manufacturing production line of receivers. The high-security-performance ultraviolet curing machine comprises a curing machine shell, a lamp bracket, a rotary loading mechanism, a motor, a motor shaft and a control monitoring system; the lamp bracket comprises a central column, edge brackets and a central plate; the edge brackets each comprise a transverse rod and a vertical rod; an inclined rod is arranged at the bottom of the vertical rod; the bottom of the inclined rod is connected to an ultraviolet lamp; fixed columns are arranged at the bottom of the central plate; the bottoms of the fixed columns are connected to ultraviolet lamps; the rotary loading mechanism comprises a chassis and a fixed block; a first placement base is arranged in the centre on the top of the fixed block; a first placement plate is arranged in the first placement base; the centres of the inclined surfaces on the top of the fixed block are each provided with a second placement base; a second placement plate is arranged in the second placement base; and the control system comprises a controller and a temperaturesensor. Due to the special edge brackets, omnidirectional illumination on semi-finished products in the curing machine is carried out in multiple angles; and, by means of the unique design of a 135-DEG inclination angle, the curing effect is good with the inclined second placement base on the rotary loading mechanism.

Owner:奥音精密机械(镇江)有限公司

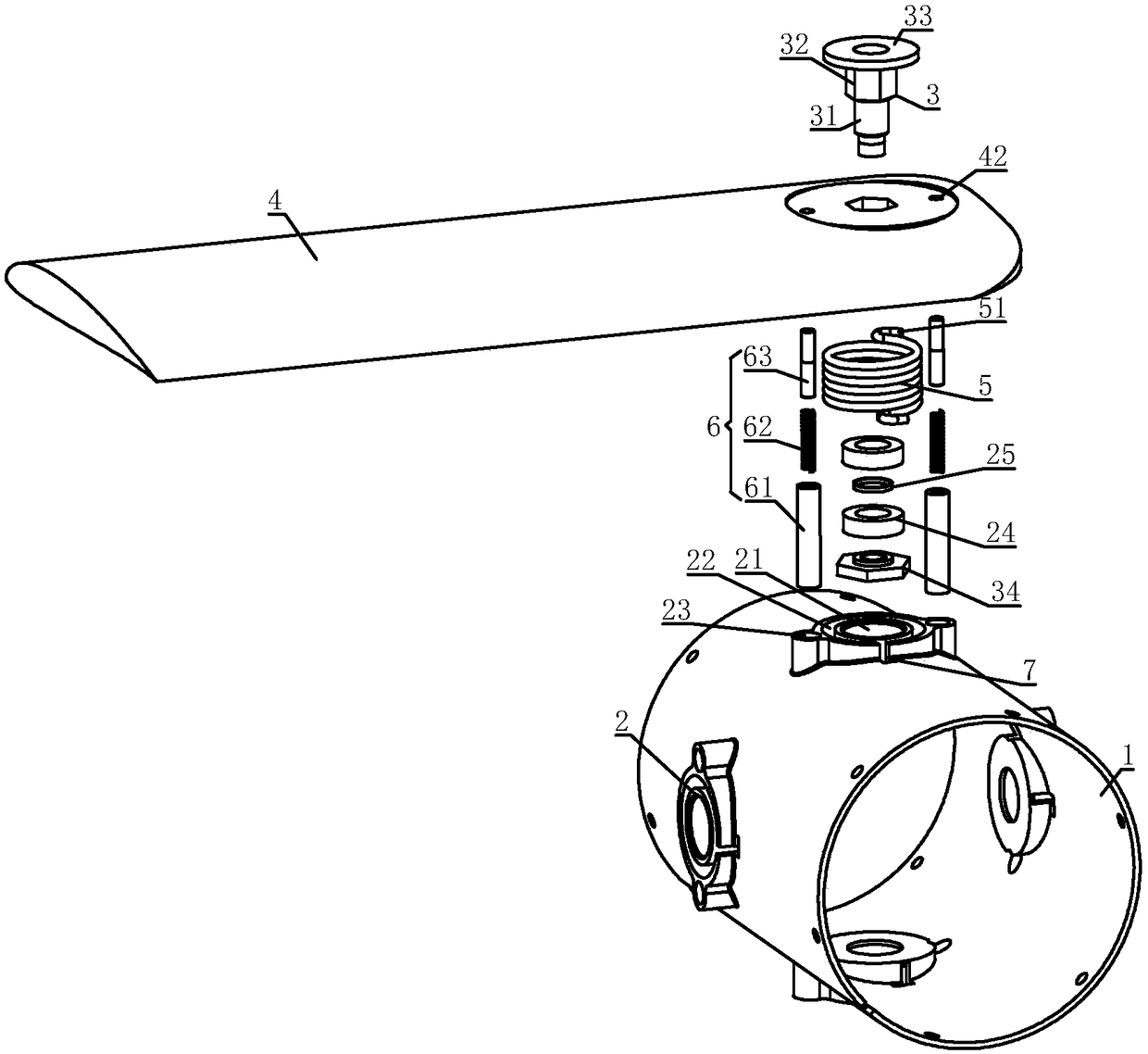

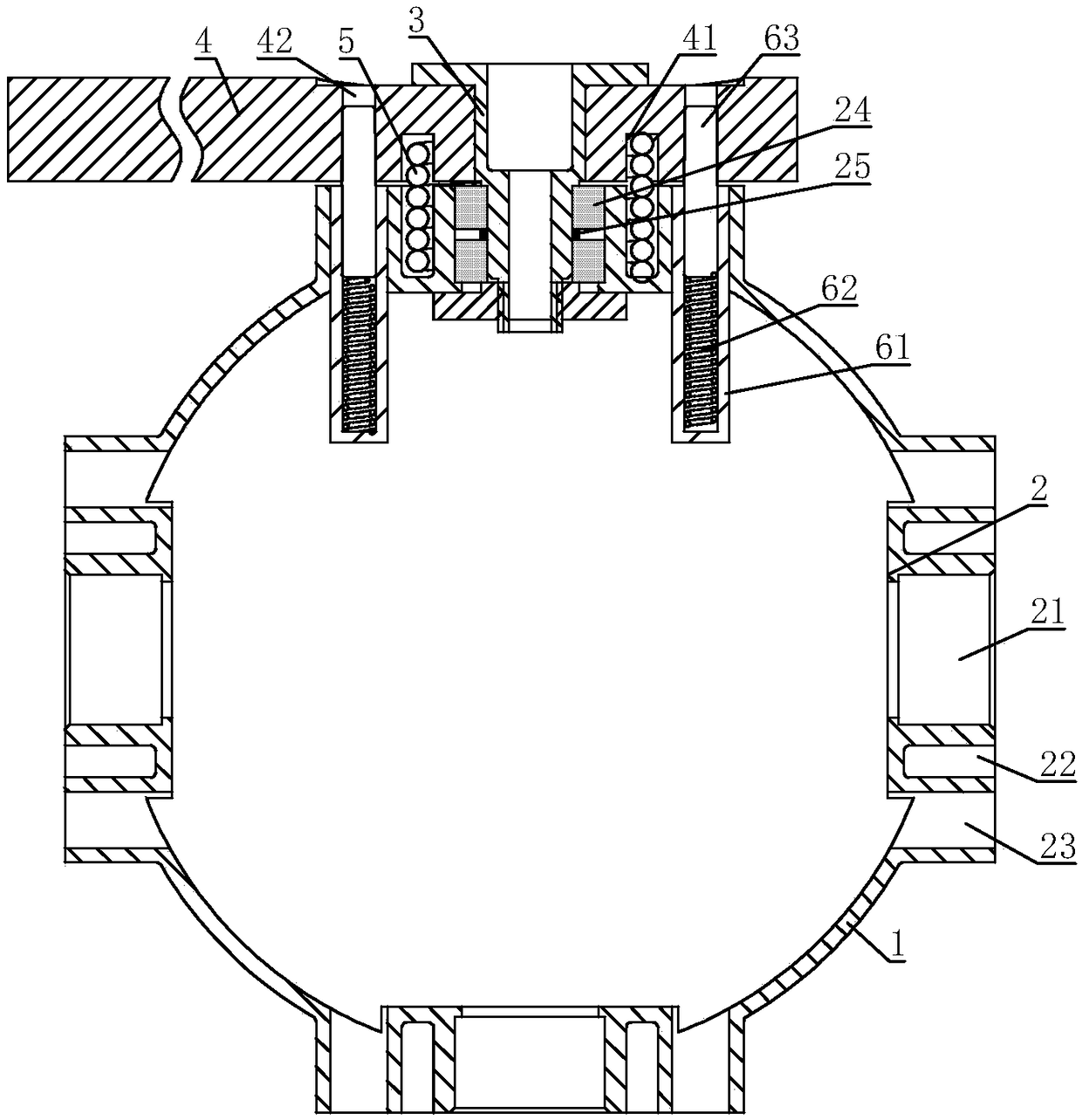

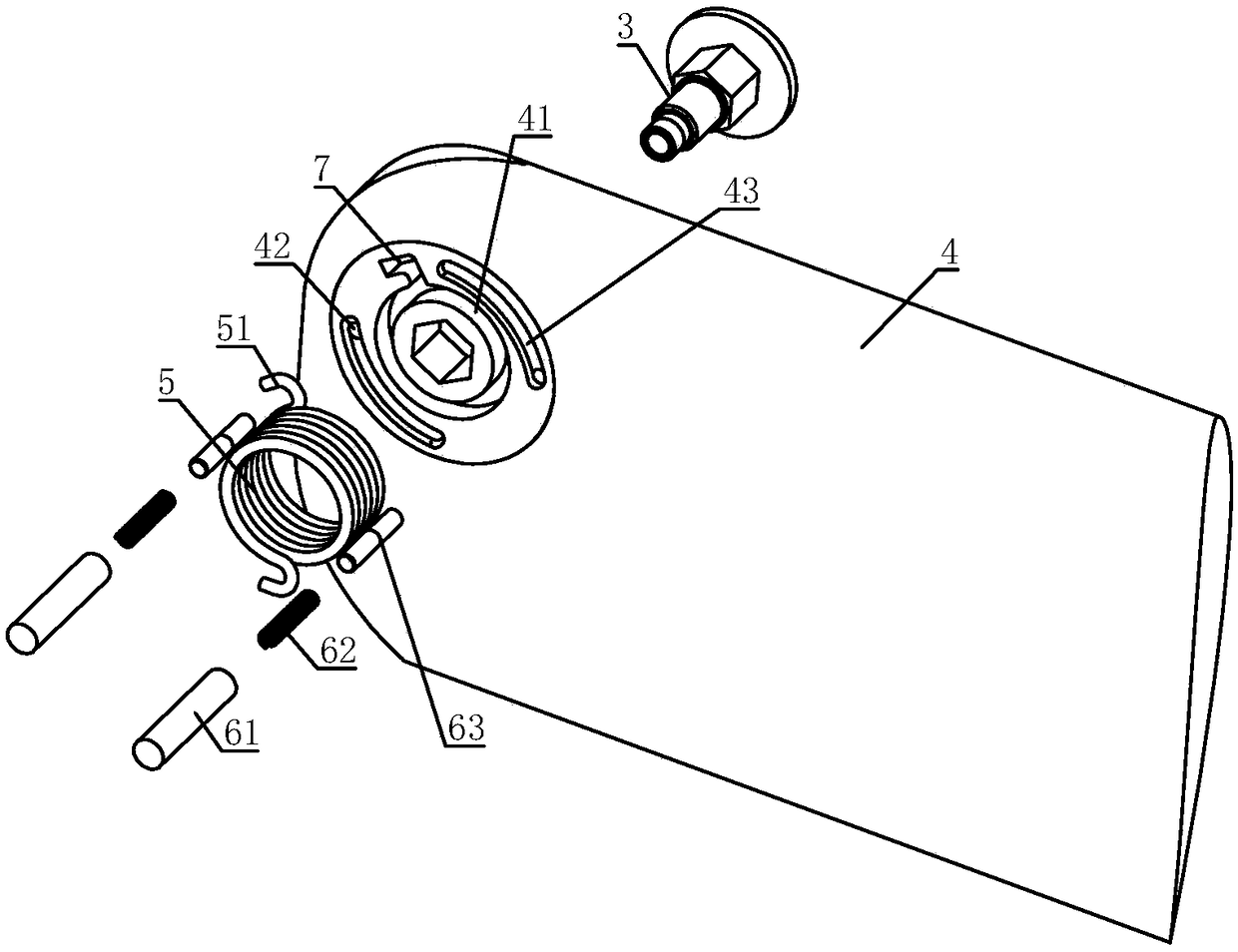

A self-locking folding unmanned aerial vehicle with stably rotating wings

PendingCN109204815ATorsional stabilizationSmooth rotationWing adjustmentsFuselagesLocking mechanismSelf locking

The invention relates to the field of unmanned aerial vehicles (UAVs), in particular to a self-locking folding UAV with stably rotating wings. The UAV comprises a bulkhead, wherein a plurality of mounting seats are arranged on the bulkhead, a mounting hole is arranged in the middle of the mounting seats, an airfoil rotating shaft is sleeved in the mounting hole, and one end of the airfoil rotatingshaft is connected with the airfoil. The mounting seats are also provided with a bulkhead annular groove, the bulkhead annular groove is concentric with the mounting hole, the wing is provided with awing annular groove, a torsion spring is sleeved in the bulkhead annular groove, the other end of the torsion spring is sleeved in the wing annular groove, one end of the torsion spring is engaged with the bulkhead, and the other end of the torsion spring is engaged with the wing. A locating mounting hole is arranged on that mounting base, a locking mechanism is arranged in the positioning mounting hole, a locking hole is arranged on the wing, and the locking mechanism is engaged with the wing when the wing is deployed. The invention provides a folding type unmanned aerial vehicle whose wingcan stably rotate and can achieve automatic positioning and locking.

Owner:成都云鼎智控科技有限公司

Hot air non-woven fabric setting machine with automatic deviation correction function for net curtain

ActiveCN106012301BAvoid frictional situationsHeating/cooling textile fabricsNon-woven fabricsPulp and paper industry

A hot air non-woven setting machine with a paired held net curtain automatic correction function comprises a machine frame, an upper held net curtain driving mechanism, a lower held net curtain driving mechanism, upper hot air boxes, lower hot air boxes, an upper hot air box lifting adjusting mechanism, an upper held net curtain and a lower held net curtain, wherein the upper held net curtain driving mechanism and the lower held net curtain driving mechanism correspond to the right side of the machine frame and are connected with the machine frame; the upper hot air boxes and the lower hot air boxes are arranged along the upper portion and the lower portion of the length direction of the machine frame from left to right; the upper hot air box lifting adjusting mechanism is arranged on the upper portion of the machine frame and connected with the upper hot air boxes. The setting machine is characterized by further comprising an upper held net curtain correction mechanism and a lower held net curtain correction mechanism, the upper held net curtain correction mechanism corresponds to the left side of the machine frame and is connected with the machine frame, the lower held net curtain correction mechanism corresponds to the lower portion of the upper held net curtain correction mechanism and is connected with the left side of the machine frame, one end of the upper held net curtain is arranged on the upper held net curtain correction mechanism in a sleeving mode, the other end of the upper held net curtain is arranged on the upper held net curtain driving mechanism in a sleeving mode, one end of the lower held net curtain is arranged on the lower held net curtain correction mechanism in a sleeving mode, and the other end of the lower held net curtain is arranged on the lower held net curtain driving mechanism in a sleeving mode. Friction, caused by deflection of the upper held net curtain and the lower held net curtain, of the setting machine and a wallboard is avoided.

Owner:苏州圣菲尔新材料科技有限公司

Quick braking mechanism for automobile

ActiveCN109058325AIncrease frictionReduce distanceAxially engaging brakesBraking discsEngineeringBrake pad

The invention belongs to the technical field of braking and in particular relates to a quick braking mechanism for an automobile. The quick braking mechanism for the automobile comprises a brake disc,a hydraulic shell, a hydraulic column, a pressure applying mechanism, a power mechanism and the like, wherein when the quick braking mechanism for the automobile is in braking, a friction wheel in the power mechanism is in friction fit with the brake disc so that the power mechanism can provide power for the pressure applying mechanism to reduce a distance between a third fixing plate and a fourth fixing plate and increase the pressure applied to brake pad by the fourth fixing plate; and therefore, a purpose of improving a braking effect is achieved. During emergency braking, the quick braking mechanism for the automobile has the advantages that the emergency braking time of a traditional braking mechanism can be shortened and the automobile can more quickly stop after suffering an emergency situation. The possibility that the automobile suffers an accident after a driver slams on a brake in the case of an emergency is reduced, and the safety of the driver is preferably protected. The quick braking mechanism for the automobile has the advantages of simple structure and better use effect.

Owner:威海高新园区运营管理有限公司

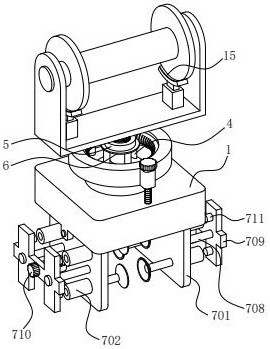

Fettling device for ceramic processing

The invention discloses a fettling device for ceramic processing. The fettling device comprises a driving motor. A top operation plate is arranged on one side of the output end of the driving motor. Apressing block is arranged on the side, away from the driving motor, of the top operation plate. A bottom cushion plate is rotationally connected to the side edge of the driving motor through a bottom connecting bearing. The bottom cushion plate and the top operation plate are connected in a clamped mode. The end, away from the output end, of the driving motor is arranged on a motor bottom clamping plate. A bolt set connecting flange is connected to the side of the motor bottom clamping plate through a plurality of motor fixing bolt sets and is welded to one end opening of a motor top fixed frame. The motor top fixed frame is clamped to the output end of the driving motor. A plurality of bottom connecting frames are welded to the outer side of the motor top fixed frame. The fettling device for ceramic processing has the beneficial effects of being novel in structure, convenient to use, novel and practical.

Owner:湖南醴陵复民瓷业机械制造有限公司

Production system and production method of ternary precursor

InactiveCN113277571AReduce contentAvoid frictional situationsDrying chambers/containersMagnetic separationForeign matterProcess engineering

The invention discloses a production system and a production method of a ternary precursor, and belongs to the technical field of ternary precursors. The production system comprises reaction equipment, solid-liquid separation equipment, drying equipment and material mixing equipment which are connected in sequence, wherein a first wear-resistant coating is arranged on the inner wall of the reaction equipment; the drying equipment comprises a drying oven body, a carrier and a drying pan used for being contained on the carrier, the drying oven body is provided with a drying cavity, the carrier is detachably arranged in the drying cavity, and a second wear-resistant coating is arranged at the joint, used for being connected with the drying pan, of the carrier; a third wear-resistant coating is arranged on the inner wall of the mixing equipment; and the solid-liquid separation equipment is provided with a rotary drum, and a fourth wear-resistant coating is arranged on the inner wall of the rotary drum. Compared with existing equipment, the production system has the advantage that pollution caused by friction of metal parts is reduced by arranging the wear-resistant coating. By adopting the production system to produce the ternary precursor, the content of magnetic foreign matter in the ternary precursor product can be reduced.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

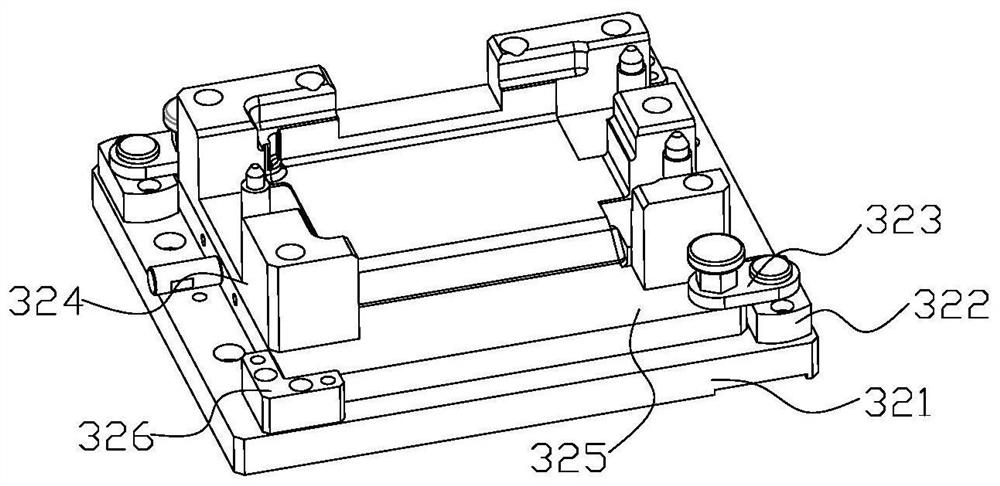

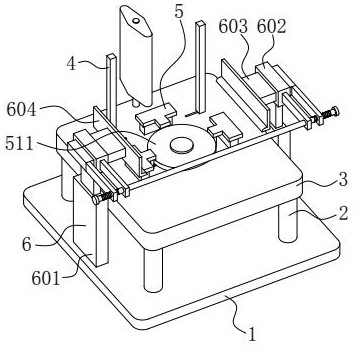

Display screen assembling, locking and carrying device and method

InactiveCN112427903AImprove replacement efficiencyLarge coverage areaMetal working apparatusEngineeringMechanical engineering

Owner:田丽玖

A graphene modified polymer injection pipeline

ActiveCN112531613BEasy and tight connectionImprove sealingCable installations in underground tubesGrapheneMaterials science

Owner:胜利油田金岛工程安装有限责任公司

Graphene modified polymer injection pipeline

ActiveCN112531613AEasy and tight connectionImprove sealingCable installations in underground tubesStructural engineeringGraphene

The invention discloses a graphene modified polymer injection pipeline, and relates to the technical field of pipelines. The graphene modified polymer injection pipeline comprises a first polymer pipeline, a second polymer pipeline is arranged on the outer wall of one end of the first polymer pipeline, and a threaded sleeve is fixedly installed on the outer wall of the first polymer pipeline. According to the technical scheme, the first gathering pipeline can be detached, part of damaged cables can be detached, troubleshot and overhauled, the situation that the first gathering pipeline needs to be damaged to be troubleshot and overhauled due to the fact that the first gathering pipeline cannot be detached is avoided, the overhauling cost is effectively reduced, accidental losses are avoided, and the practicability is enhanced; and through arrangement of a connecting block, a sealing cover, a protection sheet, a protection rod and a third sealing block, the overhaul screw can be isolated and protected, the situation that the overhaul screw is corroded by soil when deeply buried underground, and consequently a first polymer pipeline cannot be disassembled due to the fact that the overhaul screw is rusted due to corrosion during troubleshooting and overhauling is avoided, and the practicability is effectively improved.

Owner:胜利油田金岛工程安装有限责任公司

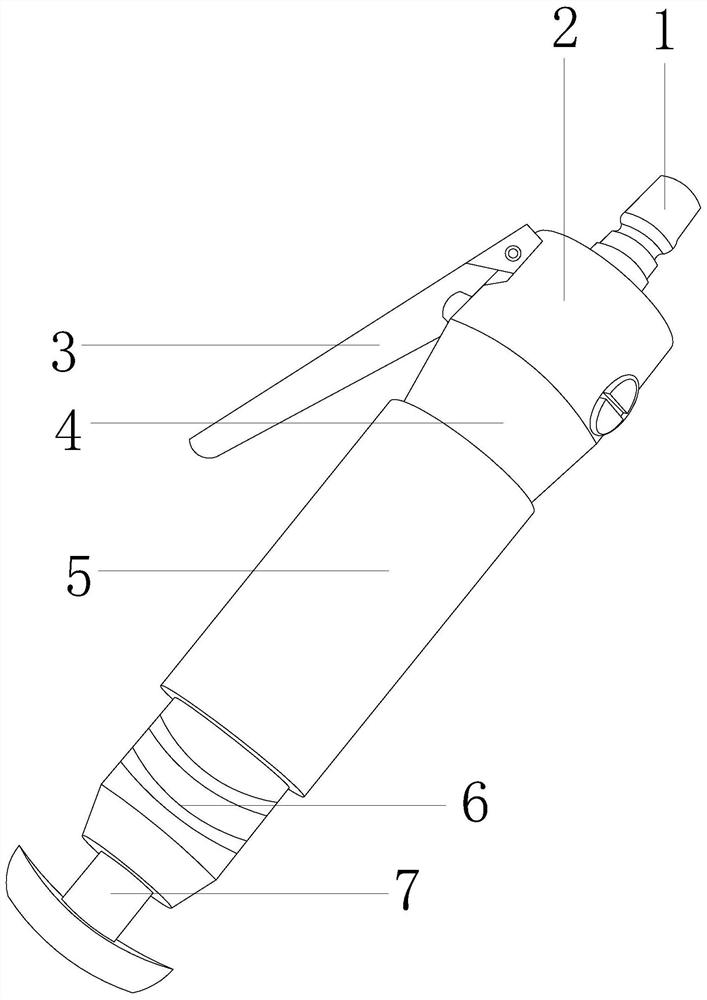

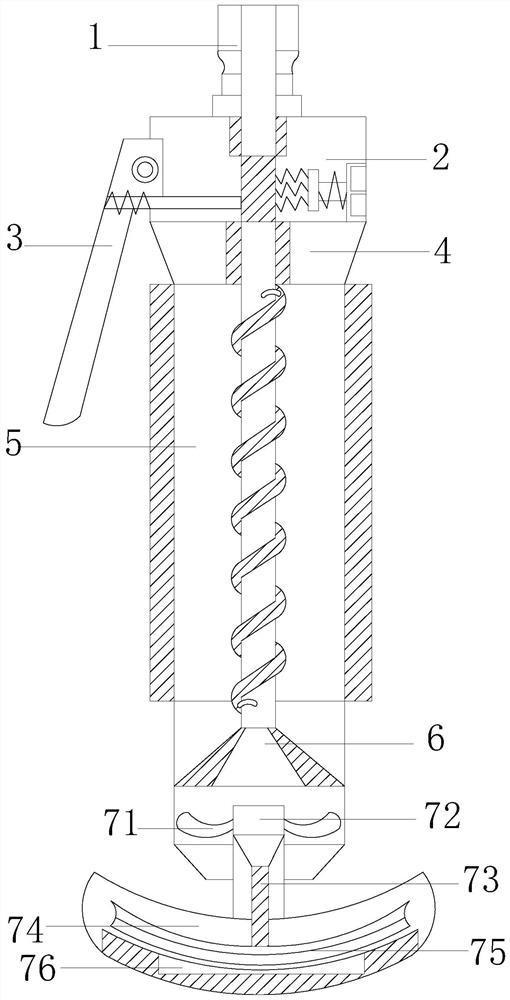

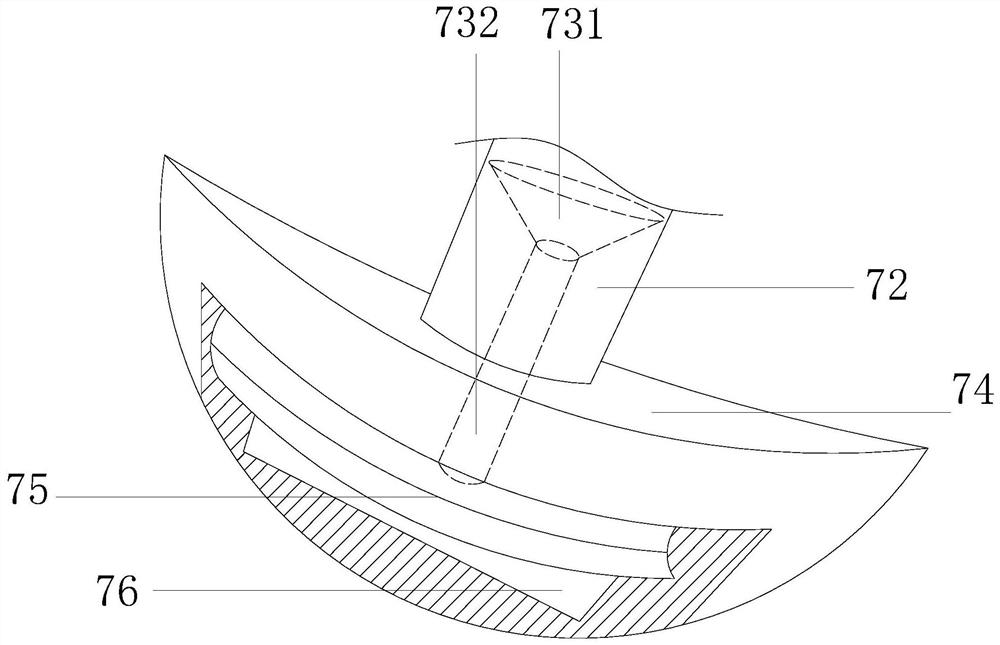

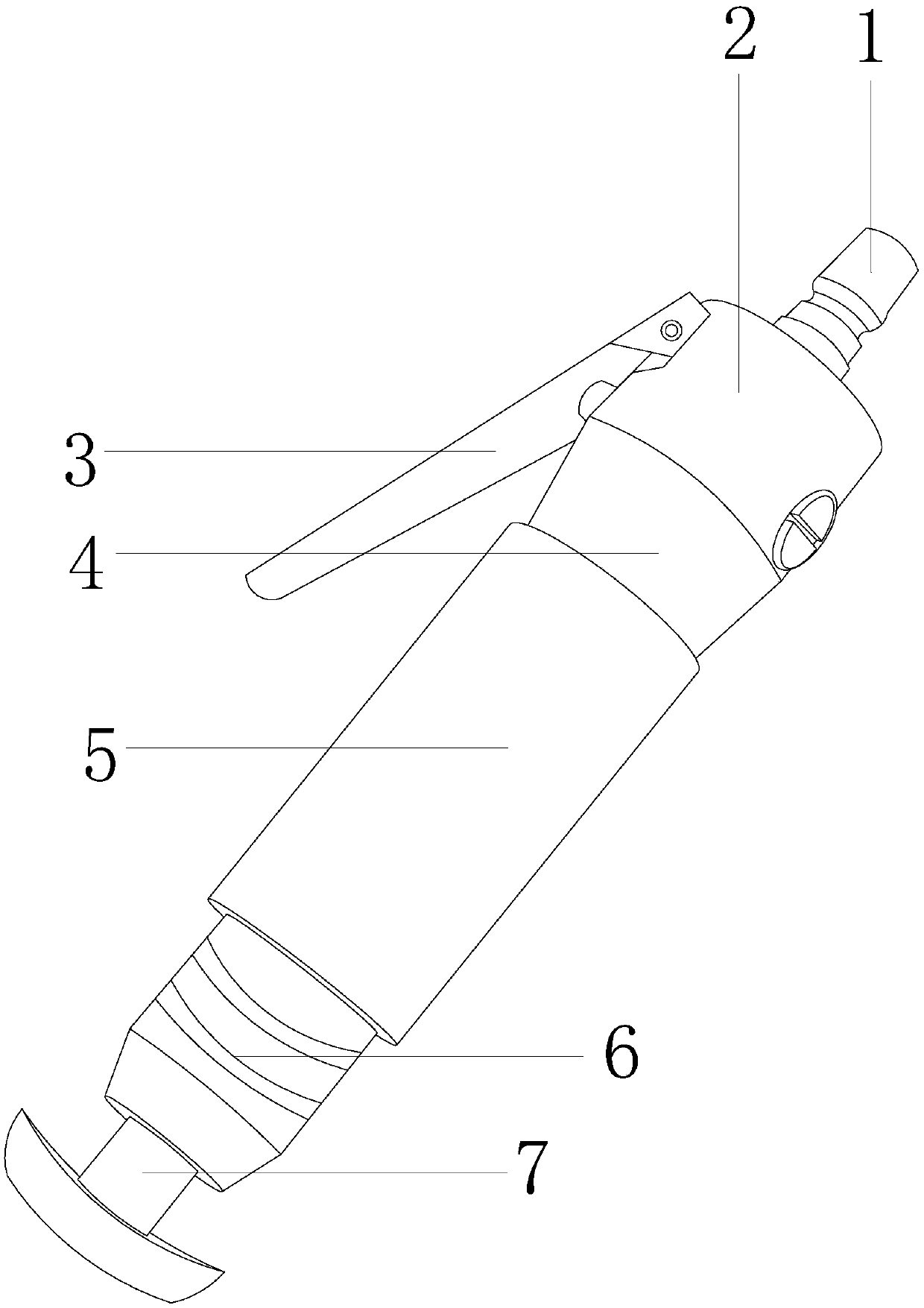

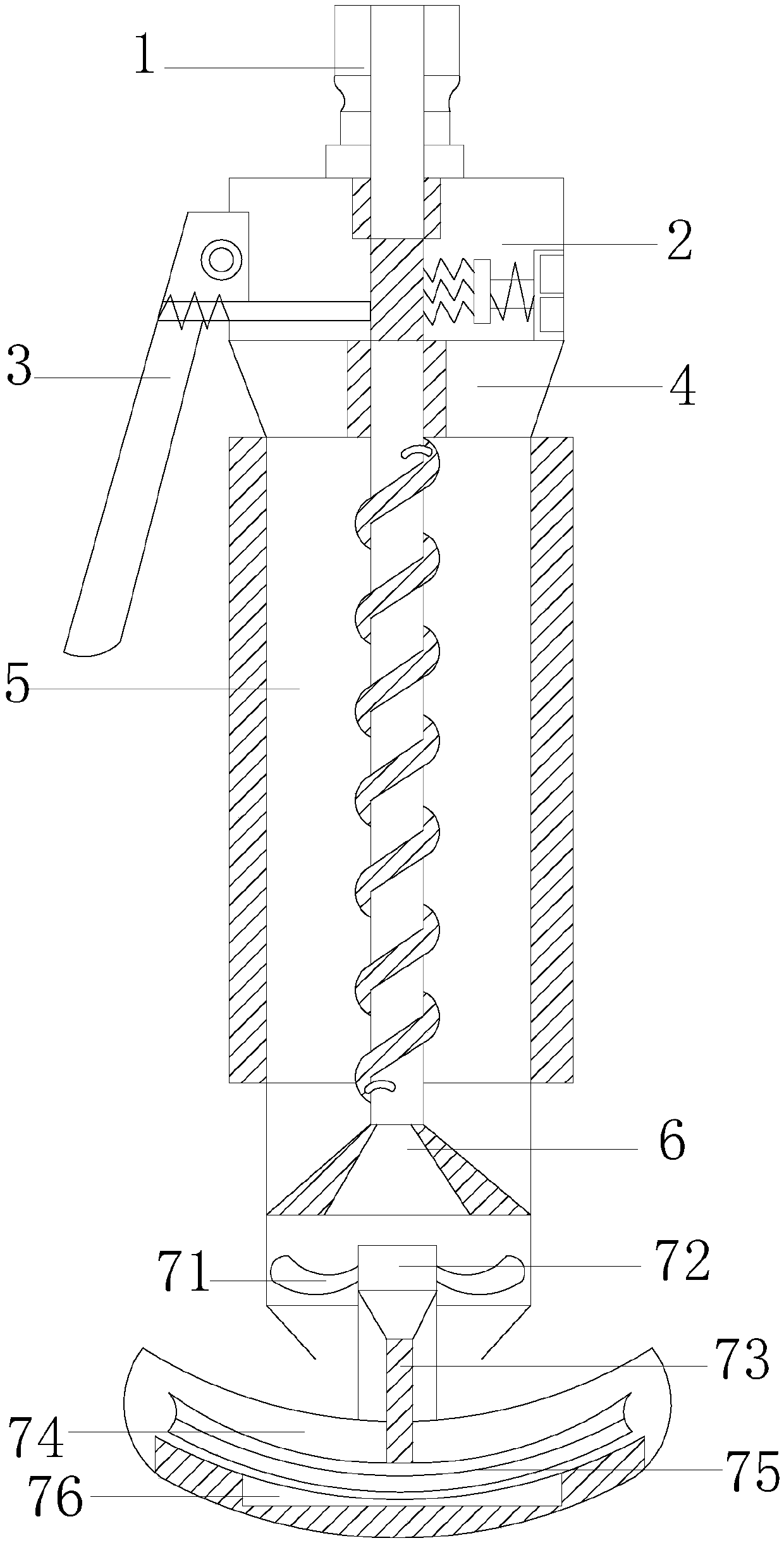

A beating device for polishing heel fabric with pull-twist buckle for making shoes

ActiveCN109645625BAvoid frictional situationsImprove smoothnessPoundingShoe trimmingHeel strikeStructural engineering

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

Consumable fixing device for 3D printing equipment

ActiveCN113352613AFirmly connectedAvoid frictional situationsAdditive manufacturing apparatus3D object support structuresEngineeringConsumables

The invention belongs to the technical field of 3D printing, and particularly relates to a consumable fixing device for 3D printing equipment. The device comprises a mounting seat, a containing groove is formed in the top surface of the mounting seat, a hemispherical block is mounted in the containing groove, and a connecting column is mounted on the surface of the hemispherical block; and a plurality of supporting mechanisms are installed on the hemispherical block around the connecting column, a threaded sleeve is installed on the connecting column, and a sealing piece is installed on the bottom face of the threaded sleeve. A fixing mechanism is mounted on the bottom surface of the mounting seat, a [-shaped frame is mounted on the top surface of the connecting column, a fixing shaft is mounted between two vertical sections of the [-shaped frame, a winding drum is mounted on the fixing shaft, and an annular end plate is mounted at the end of the winding drum; an elastic telescopic block is mounted on the horizontal section of the [-shaped frame, and an arc-shaped block is mounted at the end part of the elastic telescopic block; the device can be stably connected to 3D printing equipment in different shapes, and stable supply of consumables is guaranteed; and the condition that the consumables rub with other parts in the printing equipment before entering a printing head can be avoided, so that the loss of the consumables is reduced.

Owner:徐州齐创制造有限公司

A kind of fast brake mechanism used in automobile

ActiveCN109058325BIncrease frictionReduce distanceAxially engaging brakesBraking discsEngineeringBrake pad

Owner:威海高新园区运营管理有限公司

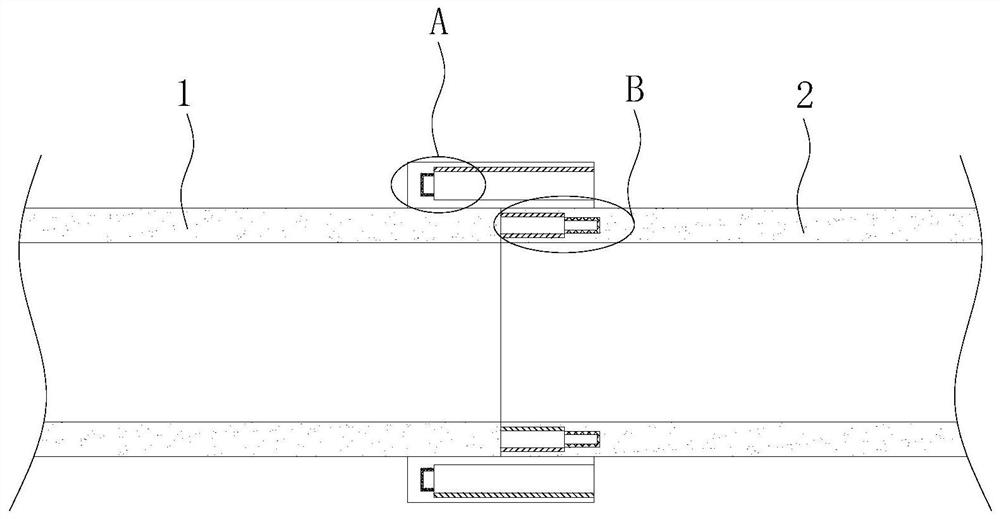

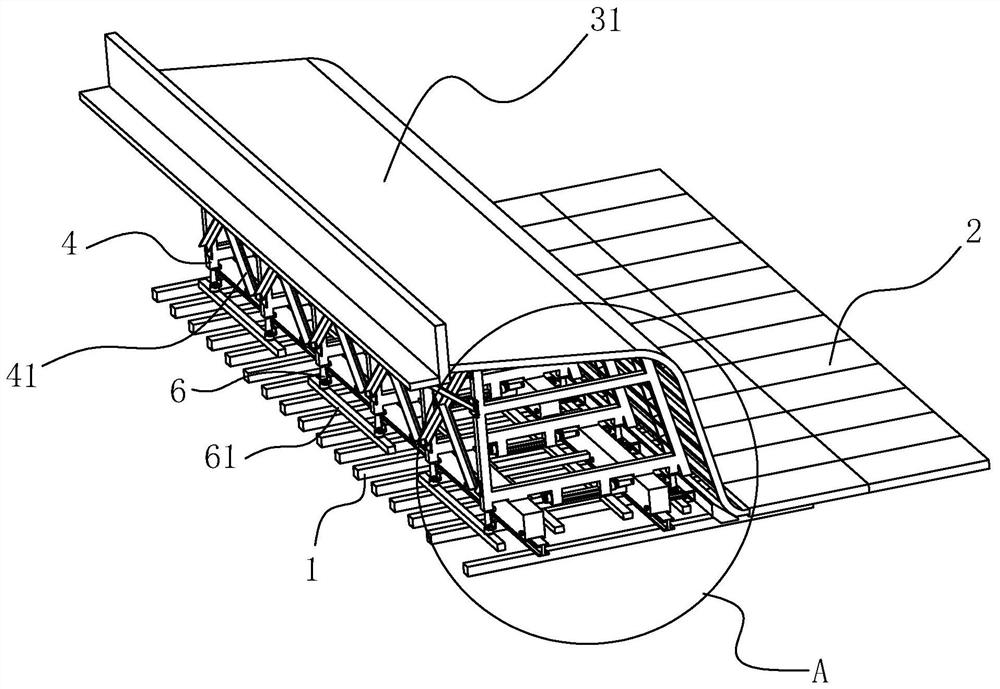

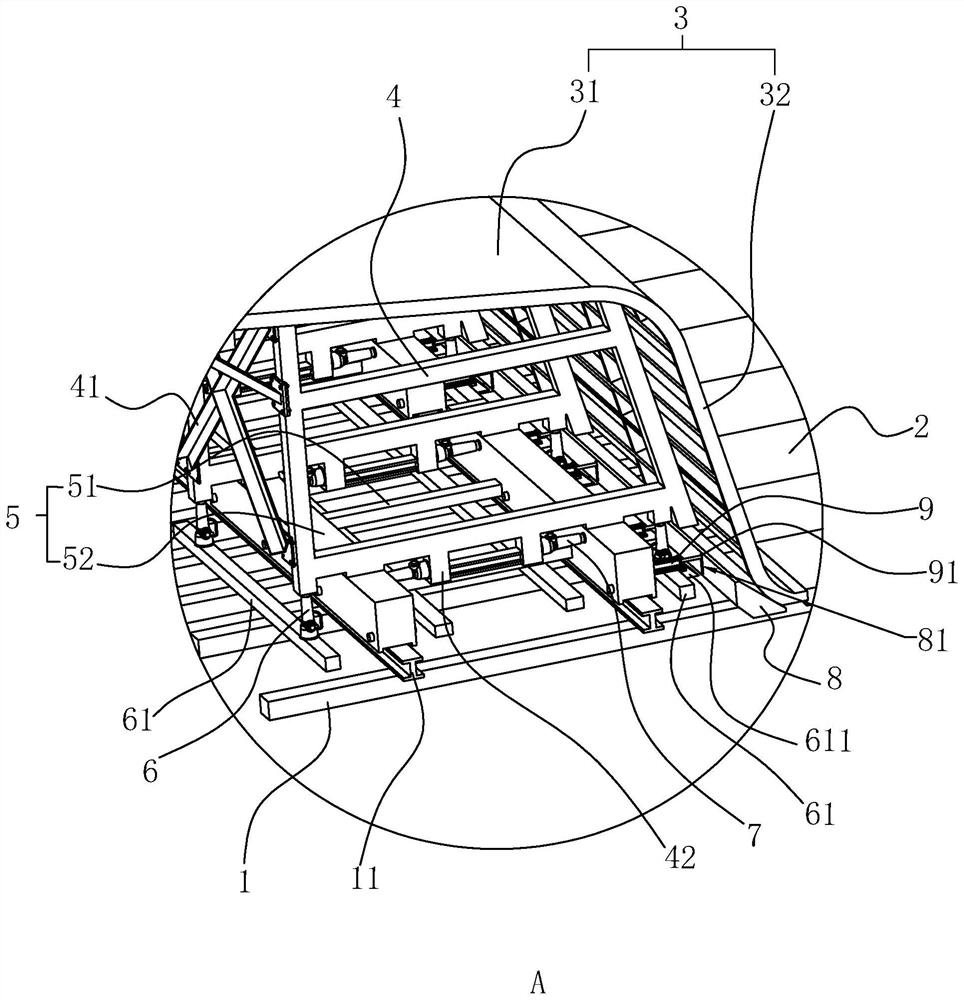

Multidirectional adjustable cast-in-place box girder integral sliding type side mold

ActiveCN113585736AAvoid frictional situationsForms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a multidirectional adjustable cast-in-place box girder integral sliding type side mold. The multidirectional adjustable cast-in-place box girder integral sliding type side mold comprises a guide rail longitudinally arranged on one side of the side mold, a mold plate trolley connected with the guide rail in a sliding and clamping mode, a mold plate support erected on the upper end face of the mold plate trolley and a side mold plate fixed to the mold plate support; and the lower end of the side mold plate is connected with one side of a bottom mold, and the mold plate trolley supports the mold plate support and the side mold plate and slides in the extending direction of the guide rail. The side mold has the effects of reducing risks and shortening the box girder construction progress.

Owner:中铁一局集团(广州)建设工程有限公司 +1

Foot pressure health detection bin

PendingCN114176570AAvoid shaking situationsSituations where it is impossible to escape from immobilizationDiagnostic recording/measuringSensorsEngineeringPhysical therapy

A foot pressure health detection bin belongs to the technical field of foot pressure detection and comprises a detection bin, two sensors and two connectors. Through cooperative use of the sensor, the connecting rod, the positioning mechanism and the transmission mechanism, after the transmission mechanism drives the positioning mechanism to move to a proper position, the sensor is taken out and replaced, then a new sensor is in butt joint with the detection bin, the transmission mechanism is loosened, the positioning mechanism can fix the sensor while resetting, and the detection efficiency is improved. The problems that in the prior art, during use, two feet need to step on two sensors, the sensors are fixed in an inner cavity of a detection bin, the sizes of the sensors are fixed, but the lengths of the two feet of a detector are different, and the detection efficiency is high are solved. The problems that the sensor needs to be dismounted and replaced due to the fact that the sensor is not long enough, and the sensor is inconvenient to dismount and replace quickly due to the fact that the whole detection cannot be carried out on the two feet of a detector easily occur in the prior art are solved.

Owner:杭州读脚兽科技有限公司

A consumable fixing device for 3D printing equipment

ActiveCN113352613BFirmly connectedAvoid frictional situationsAdditive manufacturing apparatus3D object support structuresEngineeringScrew thread

The invention belongs to the technical field of 3D printing, and specifically relates to a consumable fixing device used in 3D printing equipment, including a mounting seat, a receiving groove is opened on the top surface of the mounting seat, a hemispherical block is installed in the accommodating groove, and a connecting column is installed on the surface of the hemispherical block; Several support mechanisms are installed around the connecting column on the block, threaded sleeves are installed on the connecting column, and sealing plates are installed on the bottom surface of the threaded sleeves; A fixed shaft is installed between the two vertical sections, a winding drum is installed on the fixed shaft, and an annular end plate is installed at the end of the winding drum; an elastic telescopic block is installed on the horizontal section of the U-shaped frame, and a Arc-shaped block; the invention can be firmly connected to 3D printing equipment of different shapes, ensuring a stable supply of consumables; the invention can avoid friction between consumables and other components in the printing device before entering the print head, thereby reducing the consumption of consumables loss.

Owner:徐州齐创制造有限公司

Draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking

ActiveCN109645625AAvoid frictional situationsImprove smoothnessPoundingShoe trimmingEngineeringGrinding wheel

The invention discloses a draw-turning outward-retaining shoe heel fabric polishing beating device for shoemaking. The device structurally comprises an air tube fast connecting cap, a one-way valve port seat, a pressure plate rod, a frustum column cap, a spiral through pipe barrel, a flare exhausting barrel and a draw-turning retaining plate frame. The top end of the draw-turning retaining plate frame is inserted to the bottom of the flare exhausting barrel, and the frustum column cap and the flare exhausting barrel are nested at upper and lower ends of the spiral through pipe barrel and collinear axially. By matching of an arc shell and a C-shaped retaining plate, a plunger sleeve pushes the arc shell to open a welt turnup frame, then an upper arc groove plate and a lower arc plate are pneumatically pushed out to match with an arm arc outward turning to achieve an outward turning effect, and a turnup outwardly forms a convex block to avoid hurting of the heel; unsmooth sides of the fabric are polished by a sand wheel, turnup groove wax sealing and compacting are performed, outward-retaining action effects of beating are achieved, and wearing comfort is improved while beating frequency is reduced.

Owner:卓乃彬

Special efficient placing support for acoustic telephone receiver production

PendingCN107809735AEnsure stable placementSave spaceElectrical transducersEngineeringElectrical and Electronics engineering

The invention provides a special efficient placing support for acoustic telephone receiver production. The special efficient placing support comprises a support body and a plurality placing boxes placed on the support body; the support body comprises a placing support and vertical support columns; a cross support frame is arranged inside the placing support; the two sides of the bottom of each vertical support column are provided with triangular support blocks; the top of each of the placing boxes is provided with a first placing groove group, a second placing groove group and a central placing groove; and the bottom of each of the placing boxes is provided with a cross placing groove, and the size, structure and shape of the cross placing groove are corresponding to the cross support frame. According to the special efficient placing support for the acoustic telephone receiver production provided by the invention, a multi-layer placing support is matched with a plurality of placing boxes, so that the space is saved; the cross support frame is embedded with the cross placing groove, so that the placement is firm and the stability is high; and besides, the vertical support columns are adopted, and the triangular support blocks are uniquely designed, thus the center of gravity of the support is reduced, and the stability is high.

Owner:奥音精密机械(镇江)有限公司

Dynamic horizontal resistance displacement monitoring equipment and method based on deep foundation pit excavation soil layer

PendingCN114198613ASolve the problem of unstable fixation and shaking that affects the monitoring resultsAvoid shaking situationsMachine framesStands/trestlesEngineeringMechanical engineering

The invention belongs to the technical field of deep foundation pit excavated soil layer monitoring, and particularly relates to a dynamic horizontal resistance displacement monitoring device and method based on a deep foundation pit excavated soil layer, the dynamic horizontal resistance displacement monitoring device comprises a monitor, a supporting column and a fixing block, the fixing block is located at the bottom of the monitor, and an inner cavity of the bottom of the fixing block is in contact with the top of the supporting column; a storage groove is formed in an inner cavity of the fixing block, a positioning mechanism used in cooperation with the monitor is arranged in an inner cavity of the storage groove, and a transmission mechanism used in cooperation with the positioning mechanism is arranged in the inner cavity of the storage groove. After the transmission mechanism drives the positioning mechanism to move to a proper position, the positioning mechanism is in butt joint with the supporting column through the fixing block, the transmission mechanism is loosened, the monitoring instrument can be fixed through the supporting column while the positioning mechanism is reset, supporting of the monitoring instrument is completed, use is convenient, and the monitoring instrument can be stably connected with the supporting column.

Owner:NO 3 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY +1

An automatic lamination device for transformer iron core

ActiveCN113470965BPlay a positioning roleAvoid frictional situationsTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention belongs to the technical field of transformer accessories manufacturing, and in particular relates to an automatic lamination device for transformer iron cores, comprising a horizontal base plate, a platform is fixedly installed above the base plate through a support column, a positioning mechanism and a supporting mechanism are installed above the base plate, and a base plate is installed on the base plate. There is a stacking mechanism; in the process of stacking the upper layer silicon steel sheet on the lower layer silicon steel sheet, the silicon steel sheet does not contact the vertical rod, so as to avoid the situation of friction between the edge of the silicon steel sheet and the vertical rod; In the process of installing the splint after the sheets are stacked into an iron core, the limiting effect on a single wedge block is released in turn, so that the lifting block and the supporting plate move downward under the action of their own gravity, and the supporting plate and the bottom surface of the bottom silicon steel sheet separation, so as to achieve the effect that the splint can be installed without lifting the silicon steel sheet, and avoid the situation of squeezing force and friction between the silicon steel sheet and the vertical rod.

Owner:昌航电气有限公司

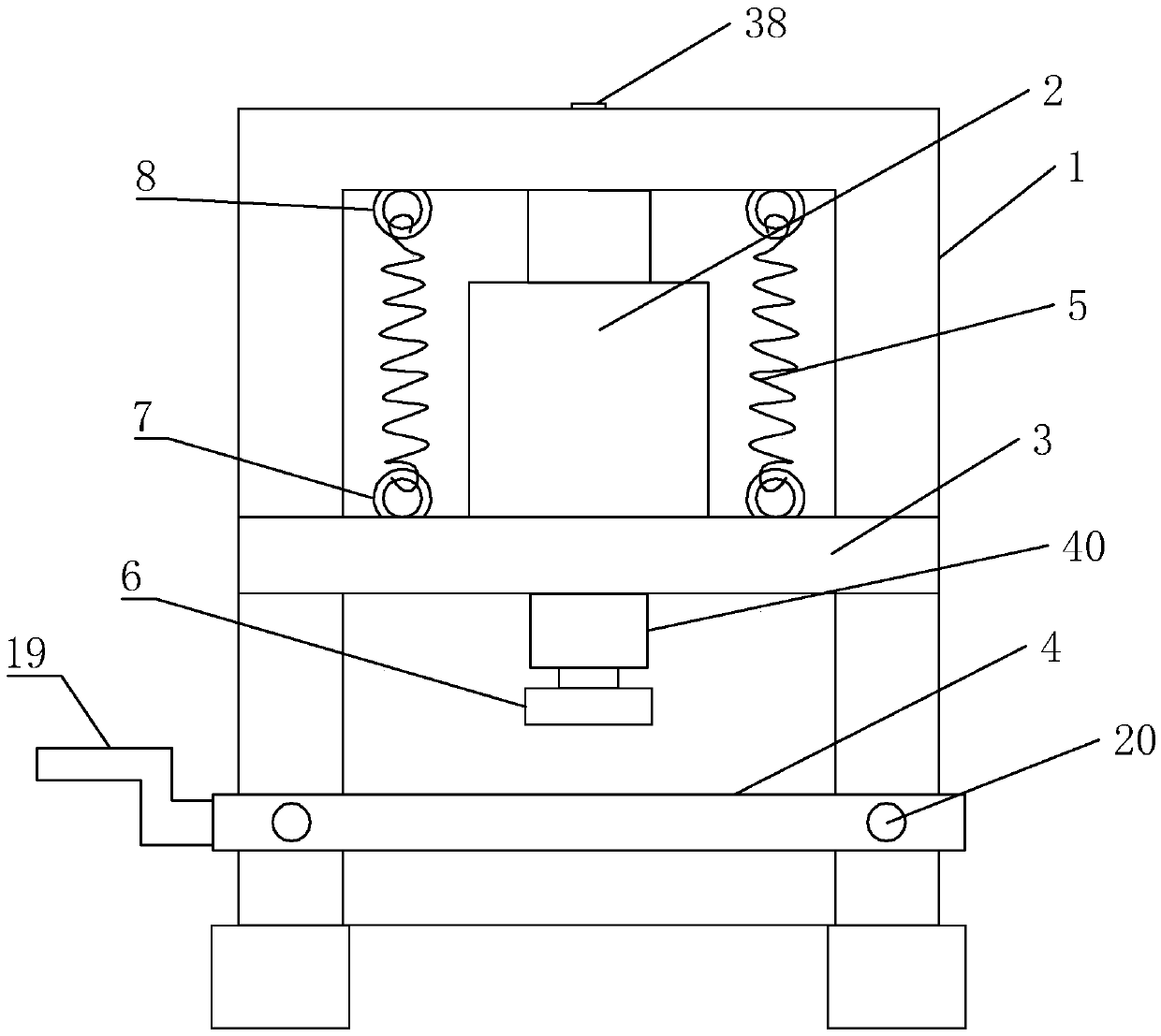

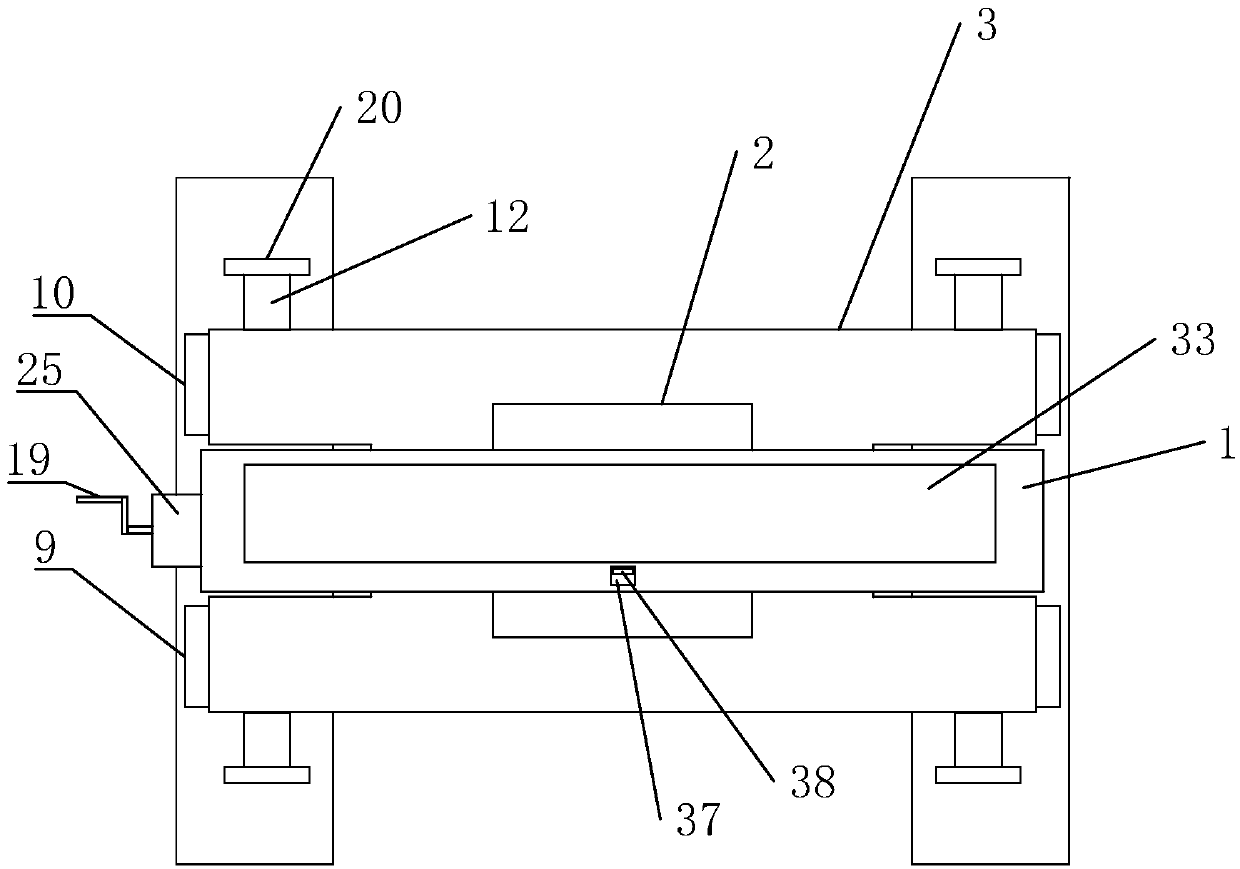

Multi-functional bearing jacking press

InactiveCN109623321AImprove up and down movement stabilityEasy to disassembleMetal working apparatusEngineeringSlide plate

Owner:衢州世邦科技有限公司

Display screen assembling screw locking mechanism and method

InactiveCN112427902APrevent malfunctionAvoid situations that cannot be dischargedMetal working apparatusComputer hardwareLocking mechanism

The invention relates to the field of display screens, in particular to a display screen assembling screw locking mechanism and method. The mechanism comprises a locking rack, a locking driving assembly and a locking head. The locking rack is fixed to a workbench, and the locking driving assembly is fixed to the locking rack. The output end of the locking driving assembly is connected with the locking head; the output end of the locking head is connected with a jig carrying mechanism, and the output end of the locking head makes contact with a display screen end cover screw hole; the locking driving assembly is used for driving the locking head to move; and the locking head is used for screwing a screw into the display screen end cover screw hole. According to the mechanism, by arranging the locking head, abrasion of a screw bit rod is reduced, and the service life of the screw bit rod is prolonged.

Owner:田丽玖

Machining device for 5G communication antenna production

PendingCN111112412ANo wear and tearAvoid frictional situationsMetal-working feeding devicesOther manufacturing equipments/toolsElectric machineryMachining

The invention discloses a machining device for 5G communication antenna production. The machining device comprises a base, wherein a fixing column is arranged at the top end of the base, a fixing rodis arranged on one side of the fixing column, a supporting plate is arranged on the side, close to the fixing rod, of the fixing column, two sets of supporting columns are symmetrically arranged at the bottom end of the supporting plate, the supporting columns are arranged at the top end of the base, an air cylinder are arranged between the supporting columns, a first motor is arranged at the topend of the supporting plate, a rotating shaft of the first motor is connected with a rotating shaft, an extrusion wheel is arranged at the end, away from the first motor, of the rotating shaft, a first connecting rod and a second connecting rod are symmetrically arranged on the side, away from the rotating shaft, of the extrusion wheel, a limiting plate is arranged at the top end of the first connecting rod, and a limiting block is arranged at the bottom end of the second connecting rod. The machining device has the beneficial effects that the first connecting rod, the second connecting rod and a limiting base are arranged to be matched, on one hand, precision machining of a radiator can be completed, and on the other hand, the limiting base cannot be abraded.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com