A preparation method of recyclable magnetic adsorption material for heavy metal treatment

A technology for magnetic adsorption materials and heavy metals, applied in the directions of alkali metal compounds, water/sewage treatment, chemical instruments and methods, etc., to achieve the effect of improving recyclability, good adsorption performance, and enhanced functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

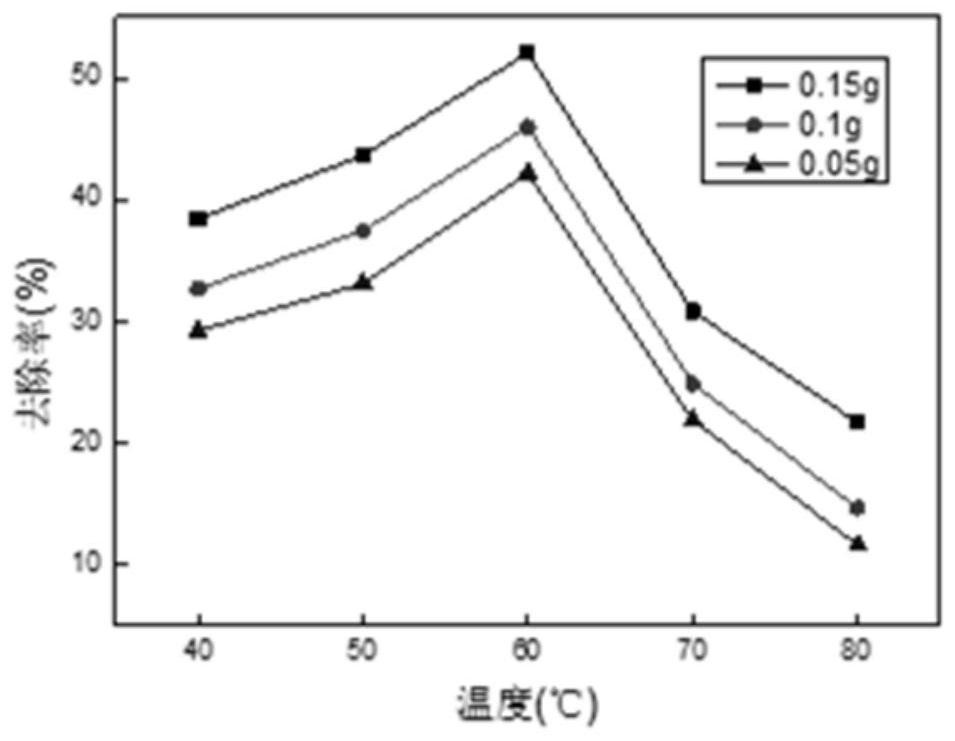

[0034] A kind of preparation method of the recyclable magnetic adsorption material that is used for heavy metal treatment, promptly is used for the preparation method of the composite material CMC of heavy metal treatment, comprises the steps:

[0035] S1: the nano-Fe 3 o 4 Ultrasonic dispersion in a three-necked flask containing deionized water to form Suspension A;

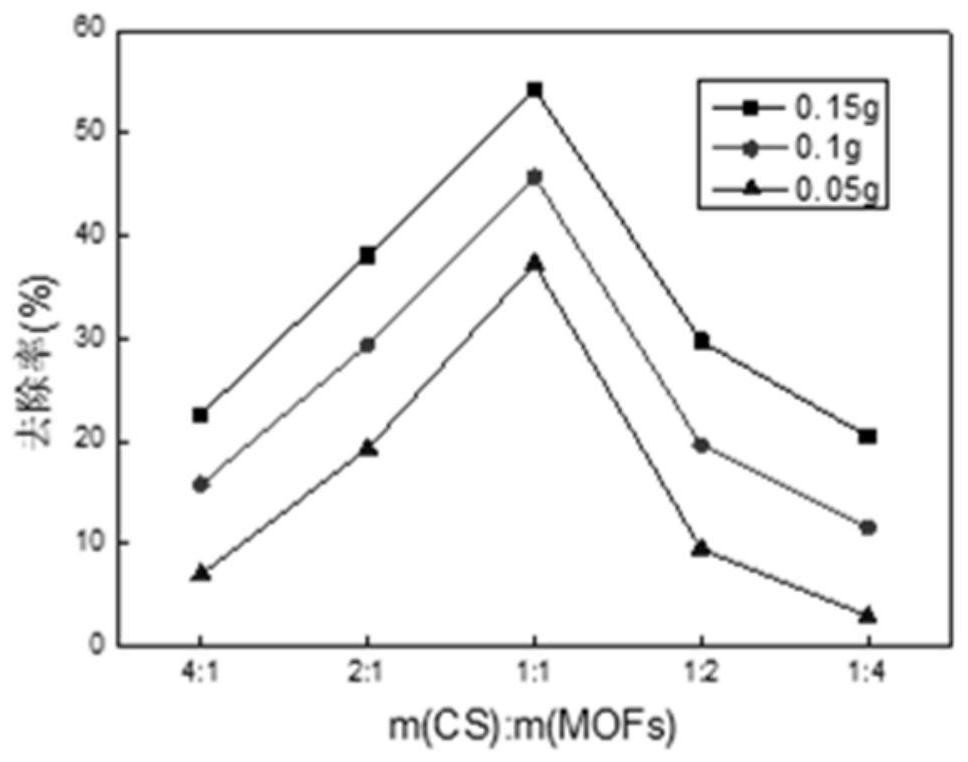

[0036]Dissolve MOFs and CS in a beaker and stir well to form a stable suspension B. The mass ratio of MOFs and CS is 1:4 to 4:1. In practice, the mass ratio of MOFs and CS can be selected as 1:4 or 1:2 , 1:1, 2:1 or 4:1;

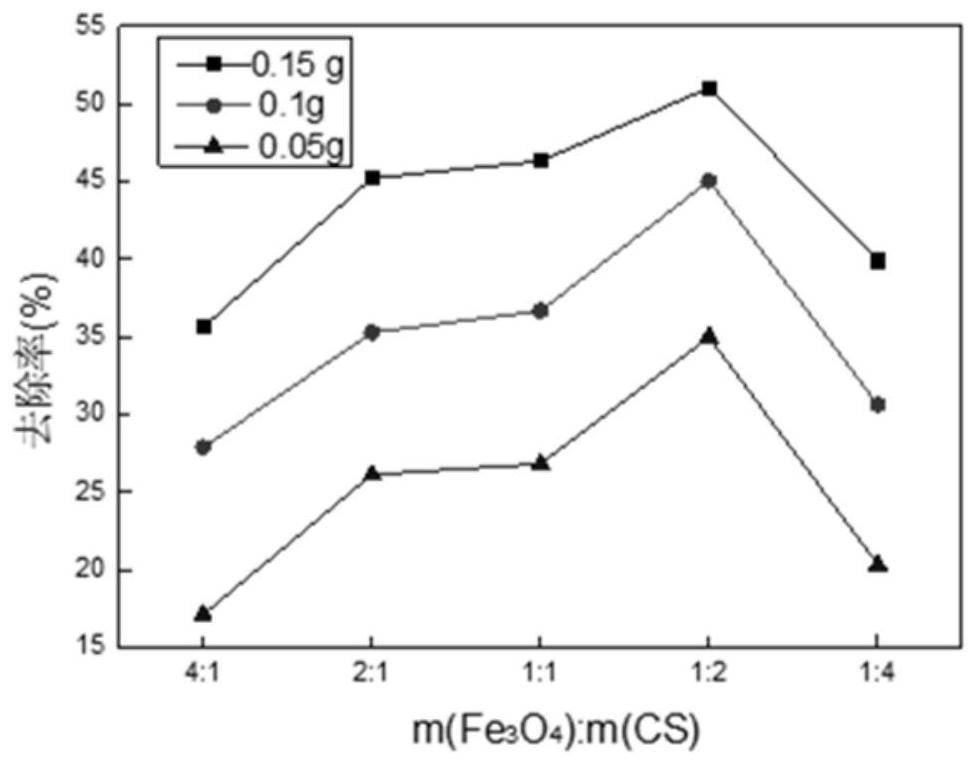

[0037] S2: According to Fe 3 o 4 The mass ratio of CS to CS is 1:4~4:1, inject the suspension B into the suspension A drop by drop, and stir rapidly to form a uniform and stable suspension, and then add pure N 2 The reaction solution is completely deoxygenated by bubbling, and during specific implementation, Fe 3 o 4 The mass ratio to CS can be selected as 1:4, 1:2, 1:1, 2:1 or 4:1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com