A lithium battery gasket cleaning station

A cleaning station and lithium battery technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of difficult to guarantee cleaning quality, low, time-consuming and labor-intensive efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

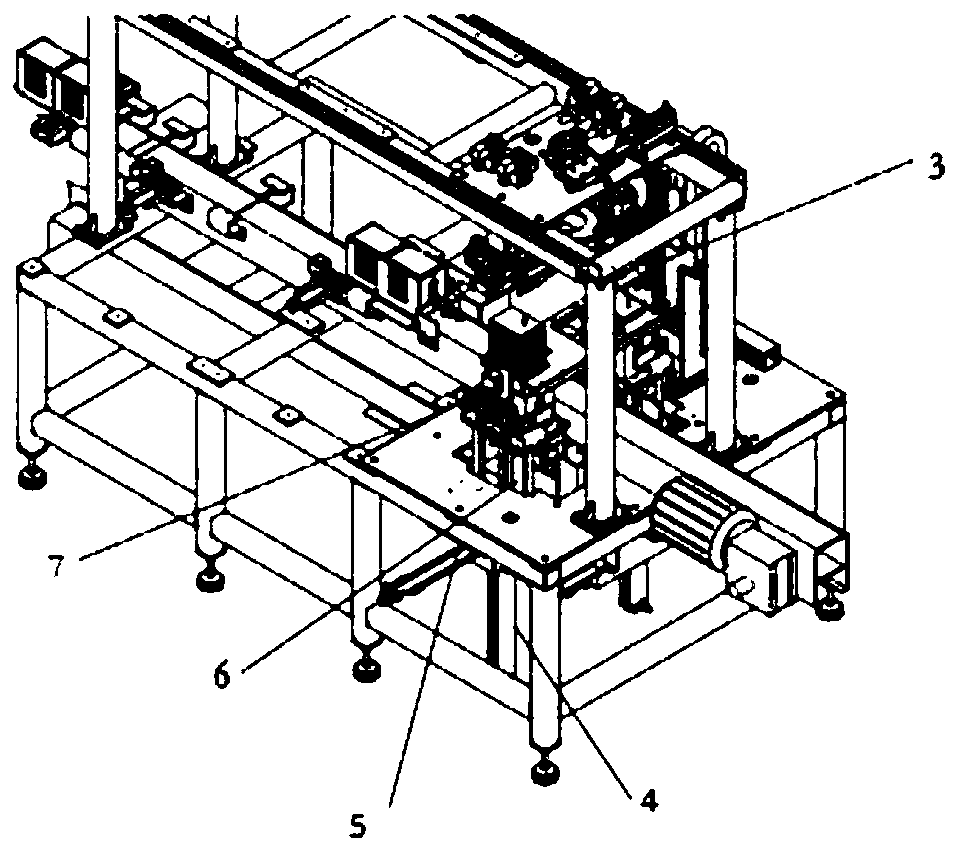

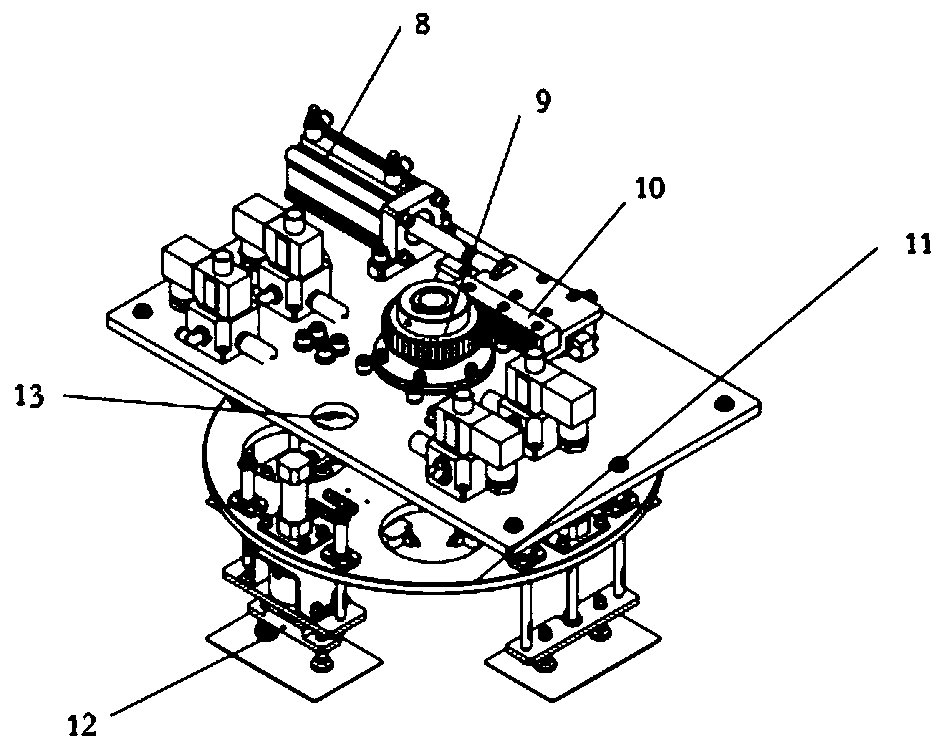

[0018] The lithium battery gasket cleaning station of the present invention includes a gasket automatic loading module, a gasket cleaning and air shower module, a gasket drying module, a gasket automatic unloading module and an empty magazine cleaning module.

[0019] In the present invention, the gaskets to be cleaned are placed in the magazines, for example, each magazine can store 300 gaskets.

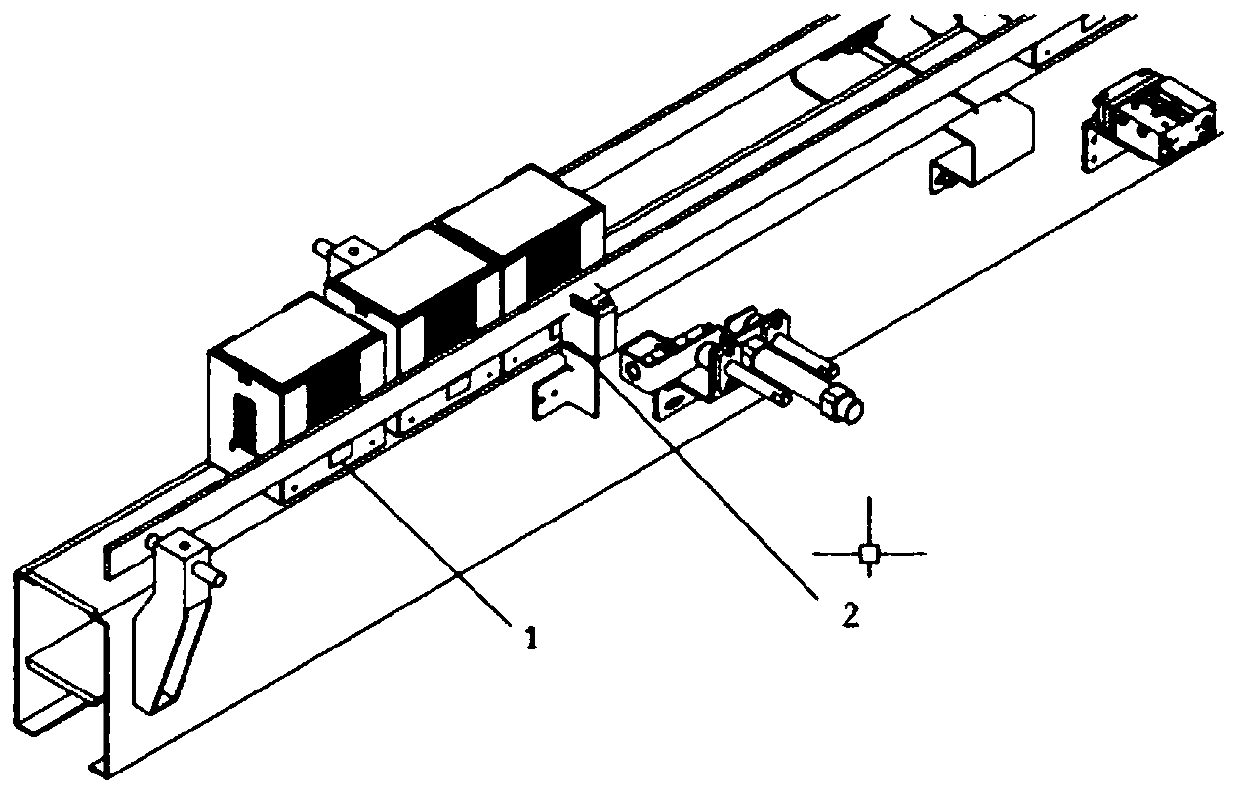

[0020] figure 1 A partial view of the gasket automatic loading module of the present invention is shown. The gasket automatic feeding module may include a first linear transmission line, a steering unit, a second linear transmission line, a baffle unit, and a feeding unit.

[0021] During operation, the clips are manually placed on the first linear transfer line for the forward transfer of the clips. The first linear transmission line is provided with a clip positive and negative detection sensor (such as a color sensor), which is used to detect the color label (such as blue) on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com