Steel plate recycling bending machine capable of reducing scrap accumulation of auxiliary positioning jigs

A technology for auxiliary positioning and positioning fixtures, which is applied in the direction of cleaning methods and appliances, smoke and dust removal, chemical instruments and methods, etc., can solve the problems of iron filings accumulation and cleaning, and achieve good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

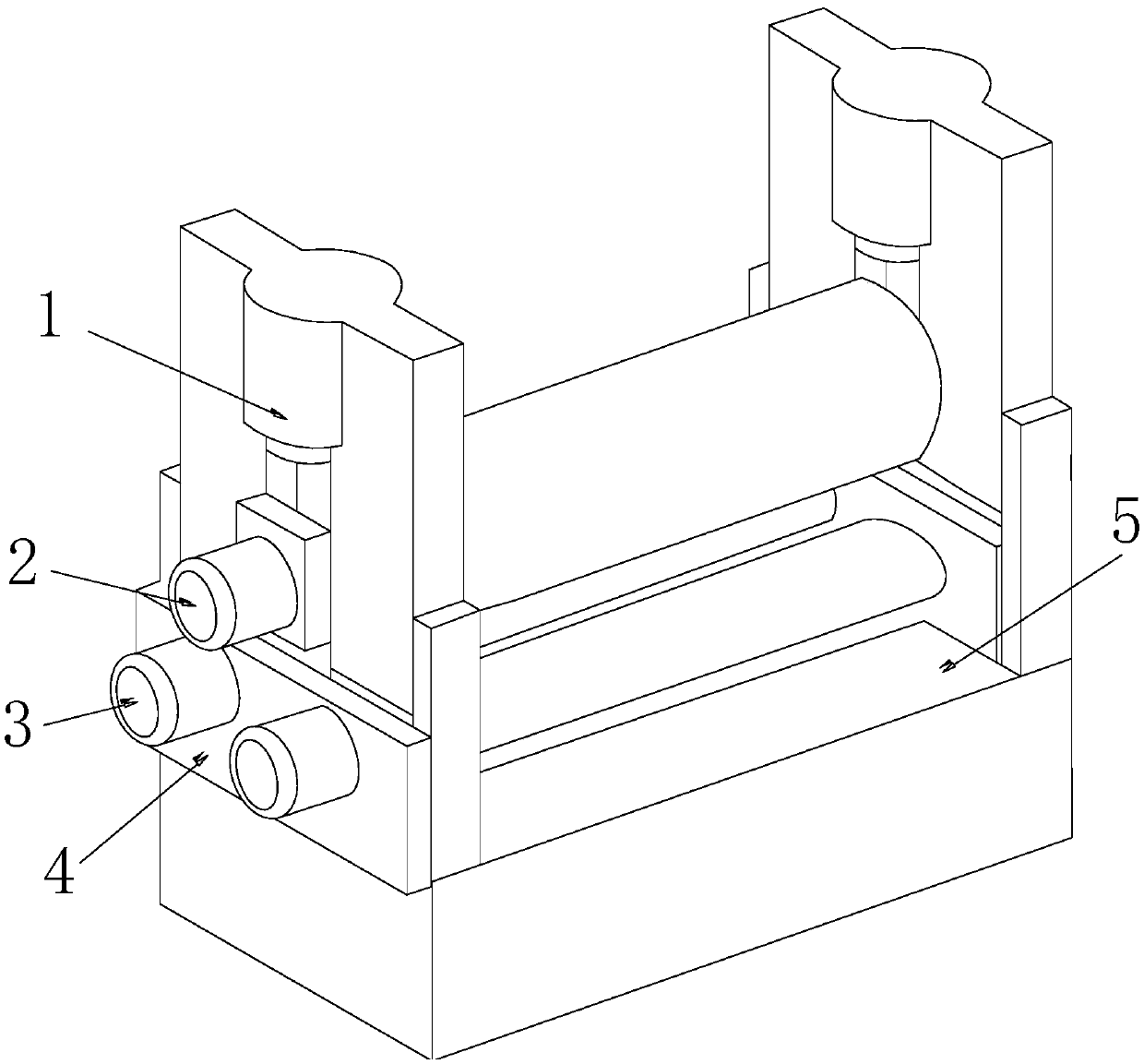

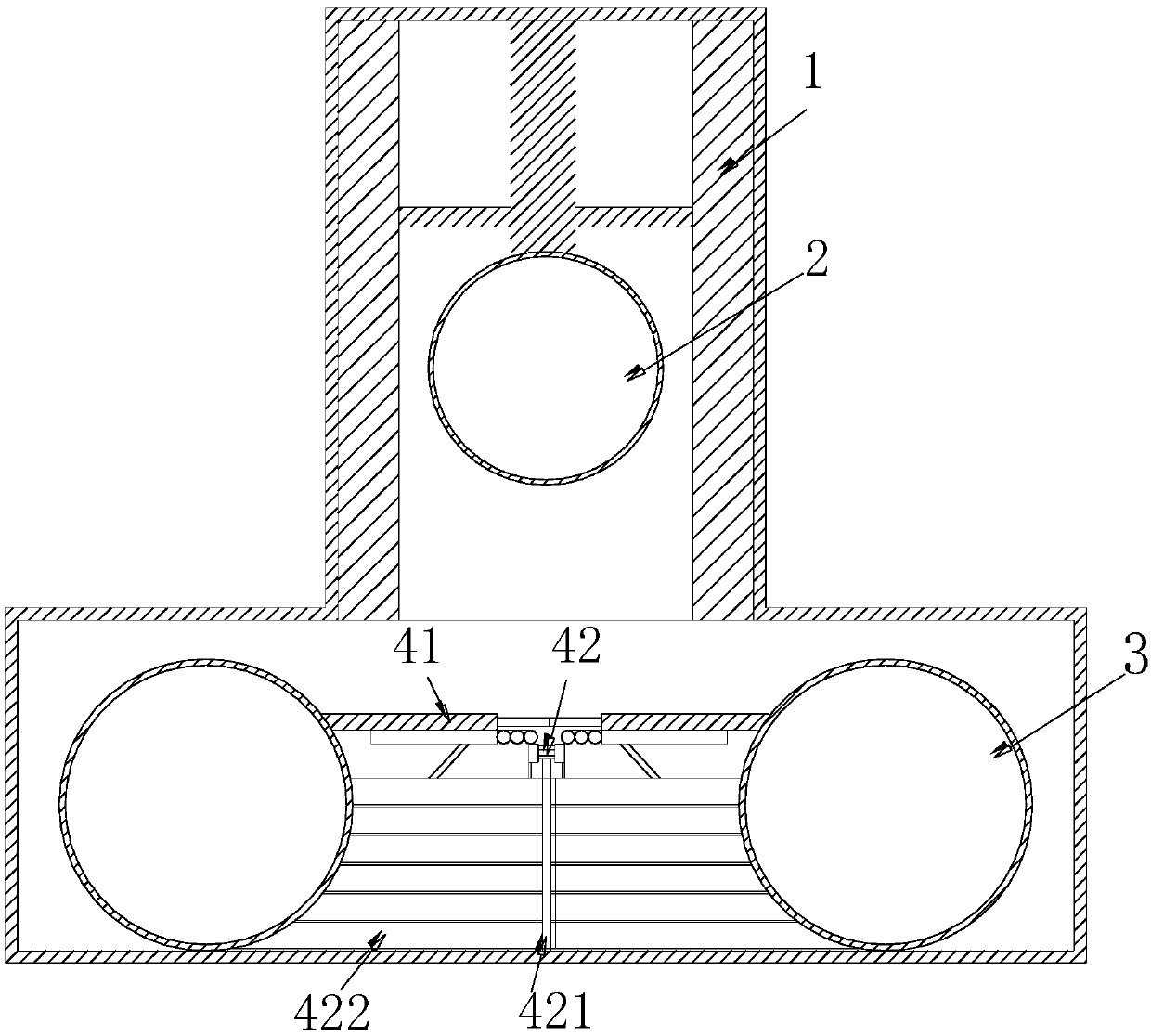

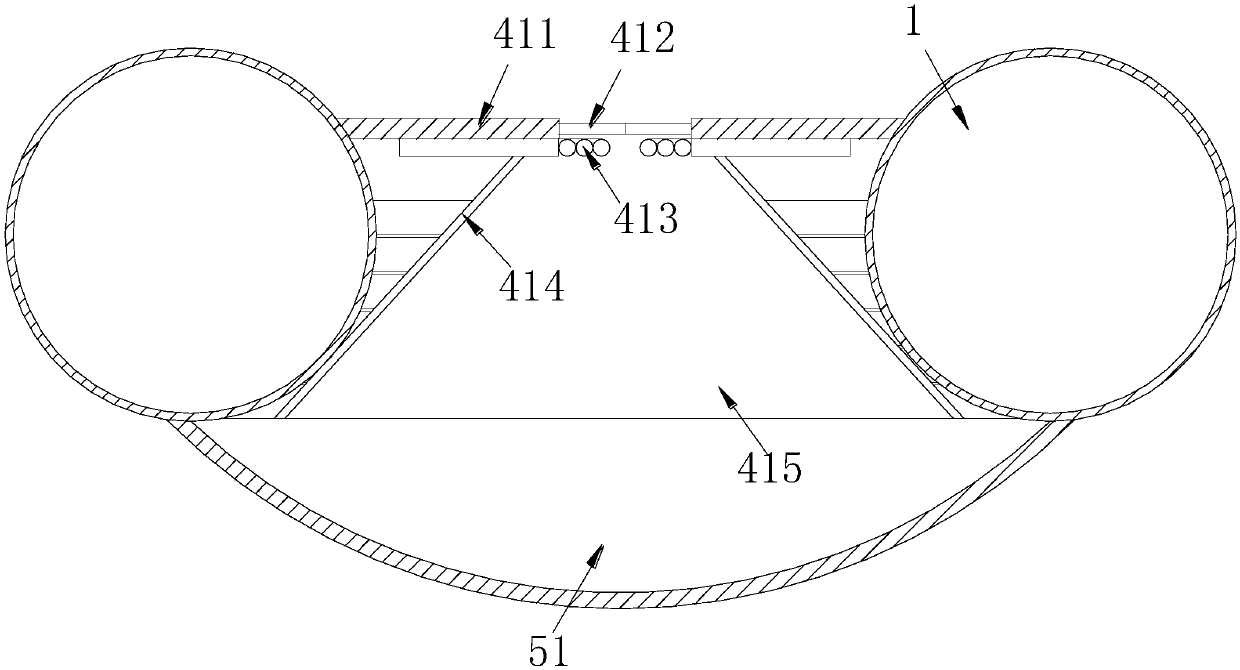

[0023] Such as Figure 1-Figure 4 As shown, the present invention provides a steel plate recovery bending machine that reduces the accumulation of auxiliary positioning jigs. Its structure includes a support plate 1, a clamping plate 2, a positioning roller 3, a positioning jig 4, and a workbench 5. A positioning jig 4 and a support plate 1 are installed on the table 5. The support plate 1 is installed vertically, and the positioning jig 4 is installed horizontally. The positioning jig 4 is equipped with two positioning rollers 3 that cooperate with each other. , The horizontal gap between the two positioning rollers 3 corresponds to the clamping plate 2, the clamping plate 2 is parallel to the positioning roller 3 up and down, and the clamping plate 2 is connected and fixed by the support plates 1 on both sides, A hinged opening and closing mechanism 41 and a negative pressure generator 42 are provided inside the positioning jig 4. The negative pressure generator 42 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com