A high-efficiency cleaning device for oil tanks

A cleaning device and high-efficiency technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of incomplete cleaning and small cleaning range, achieve good descaling effect, large cleaning range, and solve the problem of Small cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

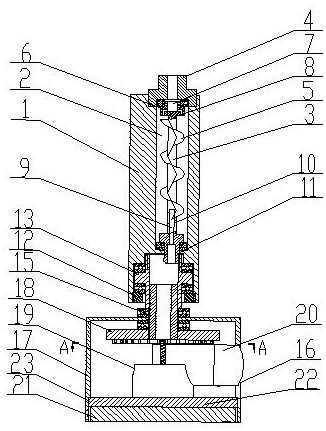

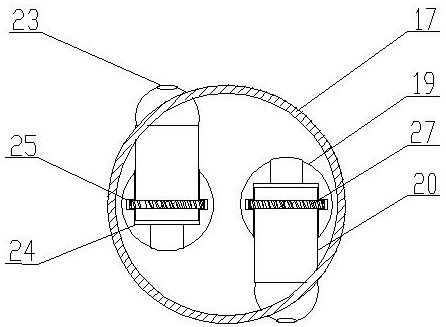

[0026] The high-efficiency oil tank cleaning device is composed of a main cylinder 1, a rotating chamber 2, a rotating shaft 3, and a rotating cleaning box. The main cylinder 1 is provided with a rotating chamber 2, and the top of the rotating chamber 2 is threaded with a joint 4. The joint 4 is in the shape of ⊥. The joint 4 communicates with the high-pressure water source through a connecting hose, and a central flow channel is arranged in the joint 4, so that the high-pressure water source enters the cleaning device through the joint 4, and the rotating shaft 3 is installed in the rotating chamber 2 below the joint 4 through ball bearings arranged up and down. .

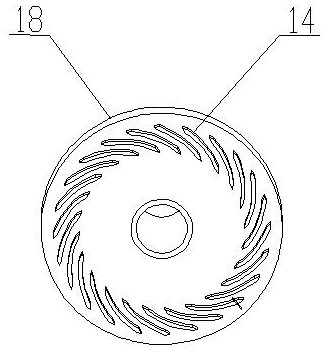

[0027] The circumference of the rotating shaft 3 is spirally provided with blades 5, and the blades 5 are fixed on the rotating shaft 3. When the high-pressure water impacts on the blades 5, the blades 5 drive the rotating shaft 3 to rotate; the top of the rotating shaft 3 above the blades 5 is provided with a flan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap