Shock absorber assembly machine

A shock absorber and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment and other directions, can solve the problems of difficult compression, large spring stiffness coefficient, and reduce the assembly efficiency of the shock absorber assembly, and achieve high compression efficiency. , the effect of increasing assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

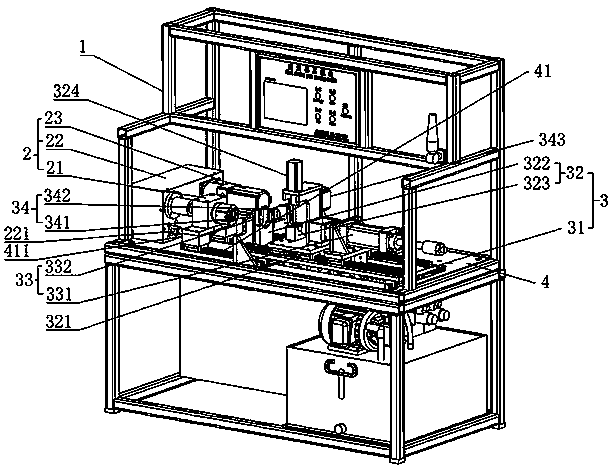

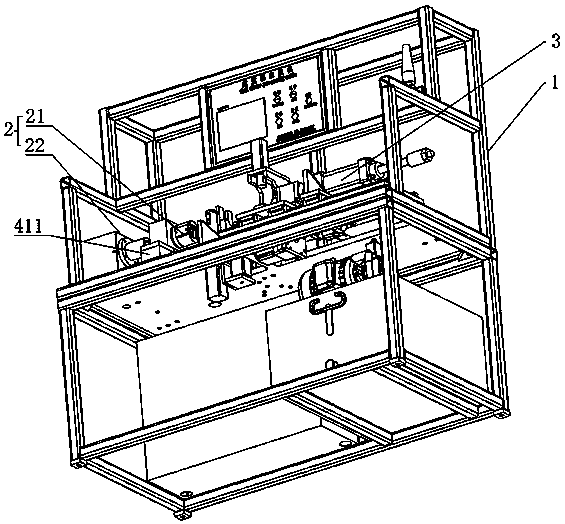

[0021]As an improved specific embodiment, the positioning mechanism 32 includes a positioning seat 321, a positioning cylinder 324, and a first positioning block 322 and a second positioning block 323 for the shock absorber to be placed. The first positioning block 322 and the second positioning block Both positioning blocks 323 are provided with slots for embedding shock absorbers, the first positioning block 322 is fixed on the positioning platform 31, and the positioning seat 321 is slidably arranged on the positioning platform 31. The second positioning block 323 is fixed on the positioning seat 321, the positioning cylinder 324 is arranged on the top of the second positioning block 323, and its push rod is set downwards, so as to be clamped with the slot of the second positioning block 323 by elongation. The shock absorber, through the cooperation of the first positioning block 322 and the second positioning block 323, can effectively use the embedded groove to realize the...

Embodiment approach

[0024] As an improved specific embodiment, the piston rod clamping mechanism 34 includes a fixed clamp block 341, a movable clamp block 342 and a clamping cylinder 343, and the fixed clamp block 341 is fixed on the spring stopper 332 facing away from the first position One side of the block 322, the clamping cylinder 343 is fixed on the position of the working platform 4 close to the spring baffle 332, and its push rod is set opposite to the fixed clamping block 341, and the movable clamping block 342 is fixed on the clamping cylinder 343 On the push rod of the clamping cylinder 343, the piston rod of the shock absorber is clamped by the clamping cylinder 343 and the fixed clamping block 341. Through the cooperation of the fixed clamping block 341 and the moving clamping block 342, the clamping cylinder 343 can be effectively used. Pushing action, the movable clamp block 342 and the fixed clamp block 341 are close to each other to clamp the piston rod, so that the piston rod ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap