Production method for EVA waterproof membrane, and plastic suction die thereof

A blister mold and a manufacturing method technology, applied in the field of EVA waterproof film production and its blister molds, can solve the problems of large sagging of the waterproof film, poor molding quality, wrinkles, etc., to improve the flatness and reduce the probability of rupture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

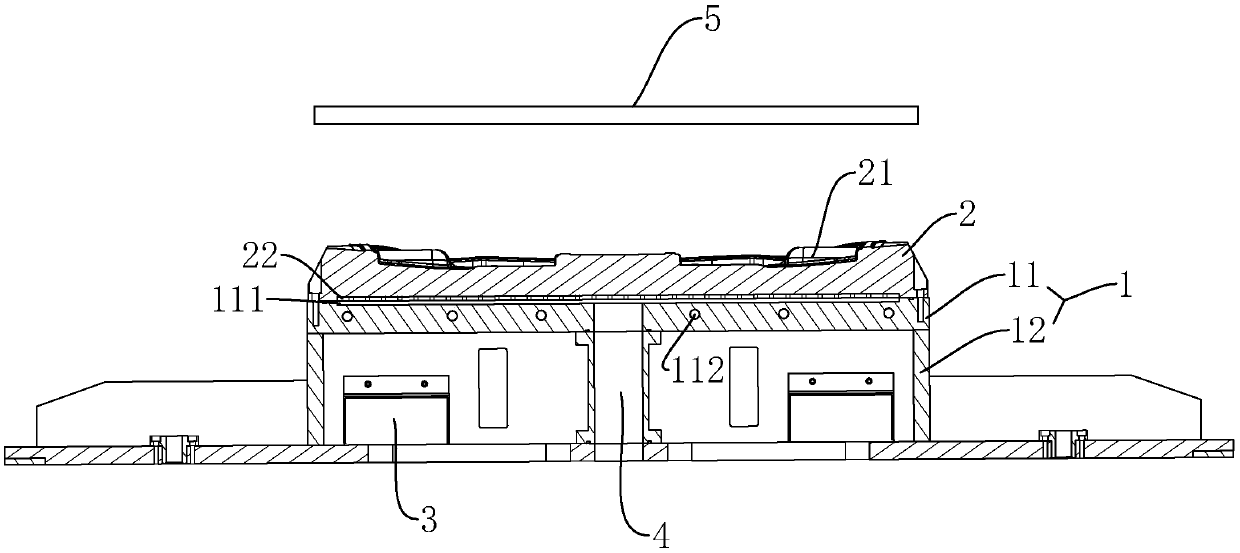

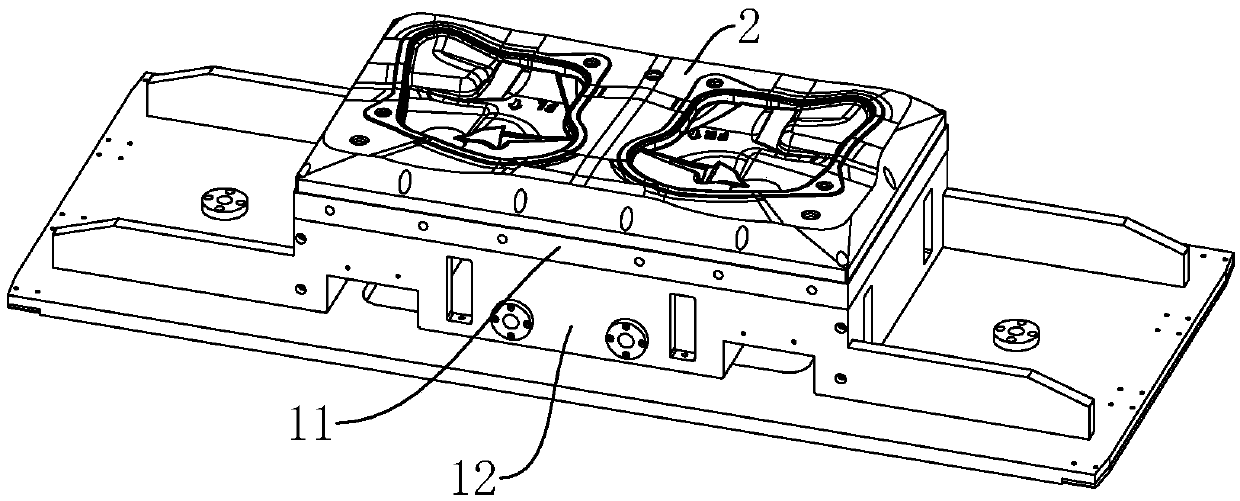

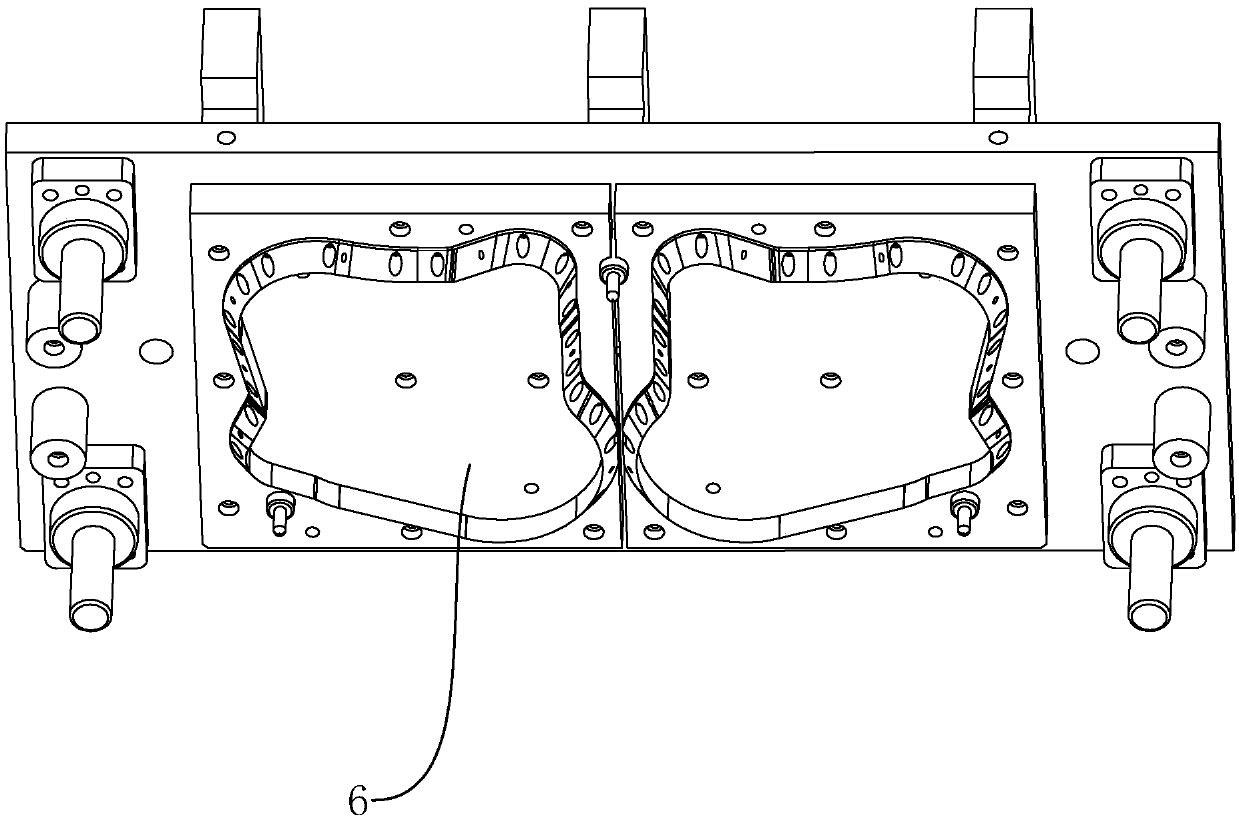

[0022] combine Figure 1 to Figure 3 The method for making the EVA waterproof membrane of the present invention and the blister mold thereof are further described.

[0023] A method for making an EVA waterproof membrane, the steps are:

[0024] a. Feeding, transfer the EVA sheet to the top of the plastic mold;

[0025] b. Clamping, using clamp 5 to compress the EVA sheet on the blister mould;

[0026] c, heating, use the heating device to heat the EVA sheet, and at the same time, the suction mold blows towards the EVA sheet;

[0027] d. Blister, change blowing air to suction in the plastic-absorbing mold, and absorb the heated EVA sheet;

[0028] E, die-cutting, utilize the die-cutting mold 6 to cut off the EVA waterproof film that is absorbed and covered in the plastic-absorbing mold from the EVA sheet.

[0029] More specifically:

[0030] a. The EVA sheet is conveyed to the vacuum forming machine through the transmission mechanism and positioned above the blister mold, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap