Inclined conveying gravity bearing free clutch transmission production line

A clutch transmission, production line technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing the friction between the tray and the roller, frequent damage to the tray roller, and increasing factory costs, so as to improve production efficiency and save money. Go to transportation time and cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

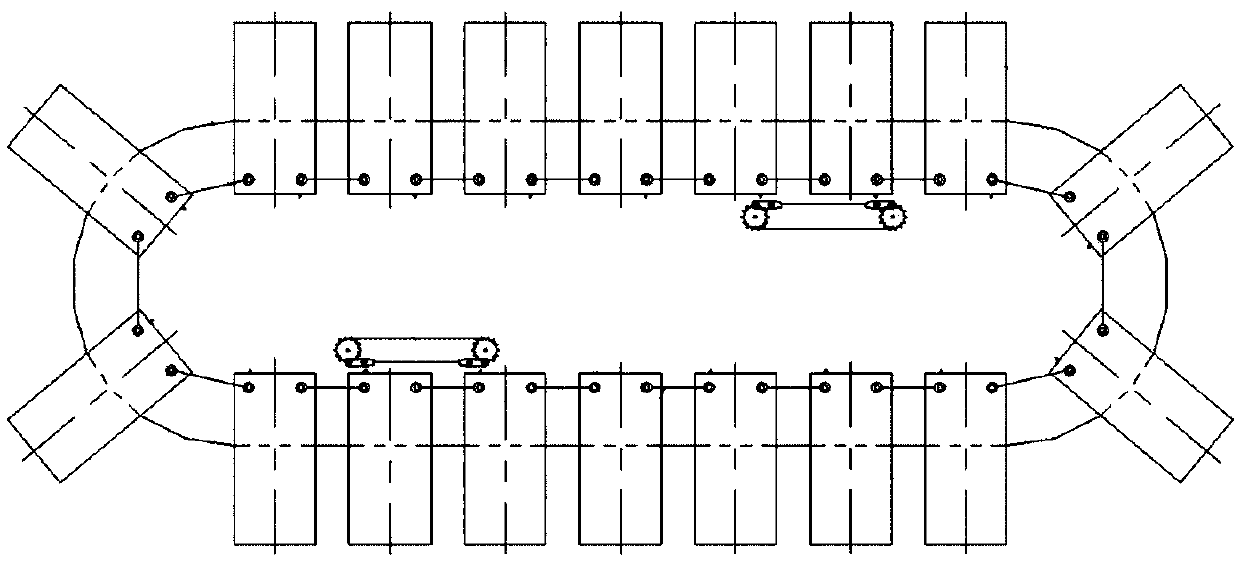

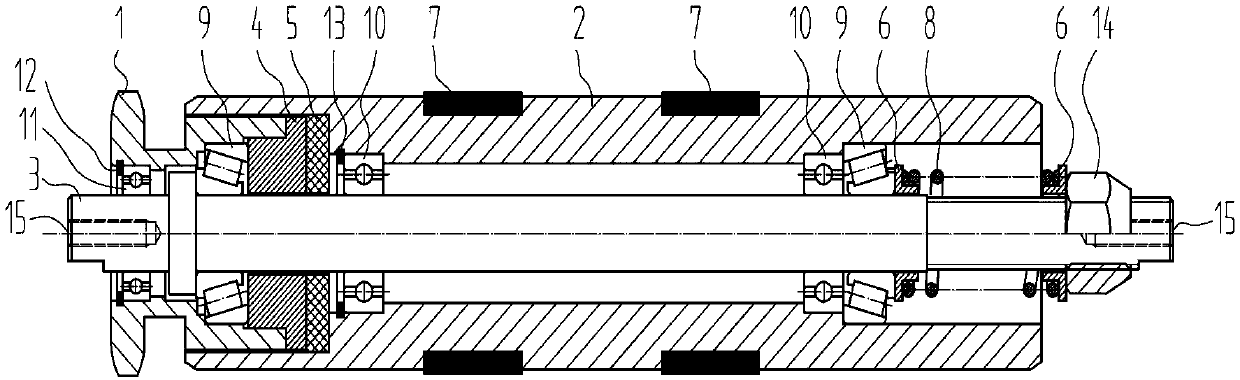

[0030] The inclined conveying gravity load free clutch transmission production line provided by the present invention includes several interconnected transmission tracks 17 and the inclined conveying gravity load free clutch transmission device transported on the drive tracks 17; the drive track 17 includes a fixed track 171 and a rotating track 172 , wherein the rotating track 172 includes a first straight track 1721 and a second straight track 1723 for the regular operation of the gravity-bearing free clutch transmission for inclined conveying, and a switching track 1722 for the orbit-changing operation of the gravity-bearing free clutch transmission for inclined conveying; The gravity load free clutch transmission device includes a sprocket 1 running on the transmission track 17, a barrel body 2, a step shaft 3, a steel plate 4, an asbestos copper wire friction plate 5, a washer 6, a plastic sleeve 7, a pressure spring 8, and a tapered roller Sub-bearing 9, first deep groove...

Embodiment 2

[0033] Such as Figure 1 to Figure 4 As shown, the inclined conveying gravity load free clutch transmission production line of the present embodiment includes several interconnected transmission tracks 17 and the inclined conveying gravity load free clutch transmission device transported on the drive track 17; the drive track 17 includes a fixed track 171 and a rotating The track 172, wherein the rotating track 172 includes a first straight track 1721 and a second straight track 1723 for the regular operation of the inclined conveying gravity load free clutch transmission device, and a switching track 1722 for the inclined conveying gravity load free clutch transmission track operation;

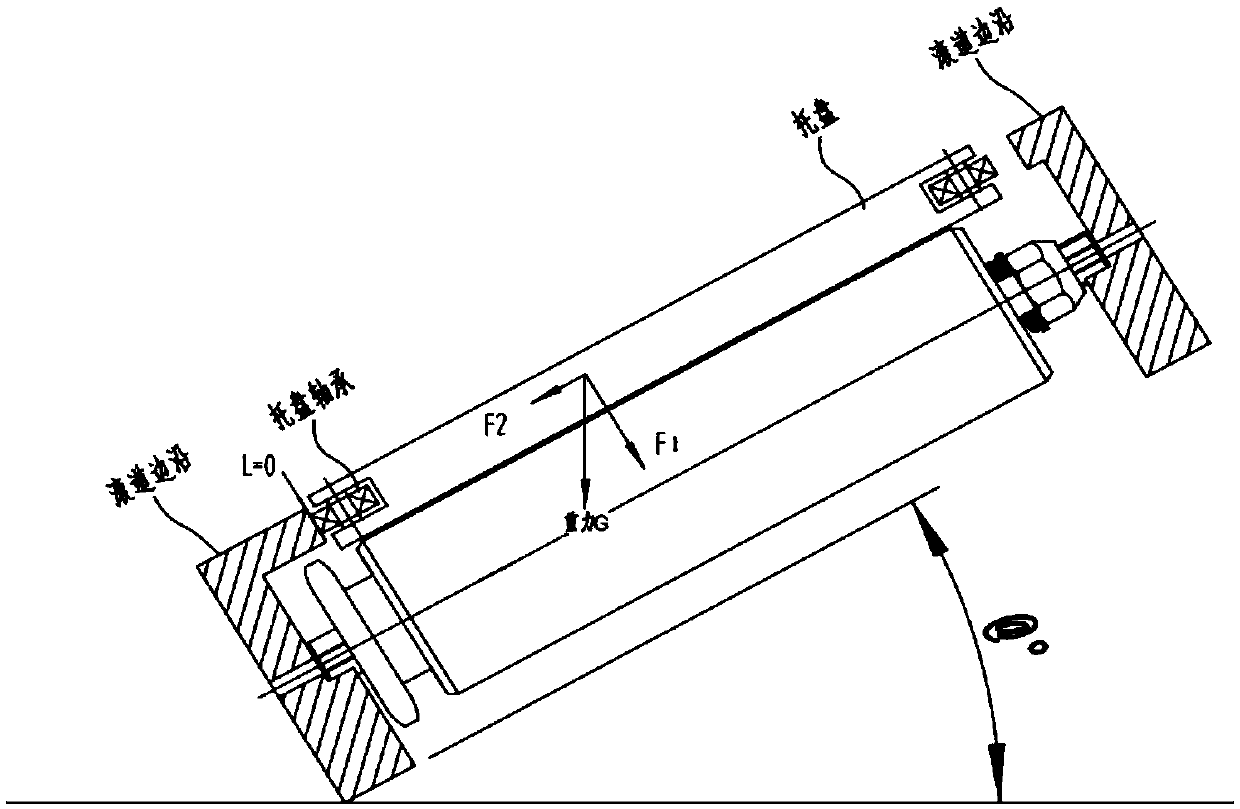

[0034] When the adjusting guide rail 161 is used instead of the self-locking anti-loosening nut 14, the gravity-bearing free clutch transmission device for inclined conveying includes a transmission assembly for driving the cylinder body 2 to rotate, the cylinder body 2, a step shaft 3 and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com