Collating device for printing

A technology for collating and placing plates, applied in the field of printing collating, can solve problems such as page damage, low work efficiency, complex structure, etc., and achieve the effects of easy maintenance, simple structure, and reduced settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

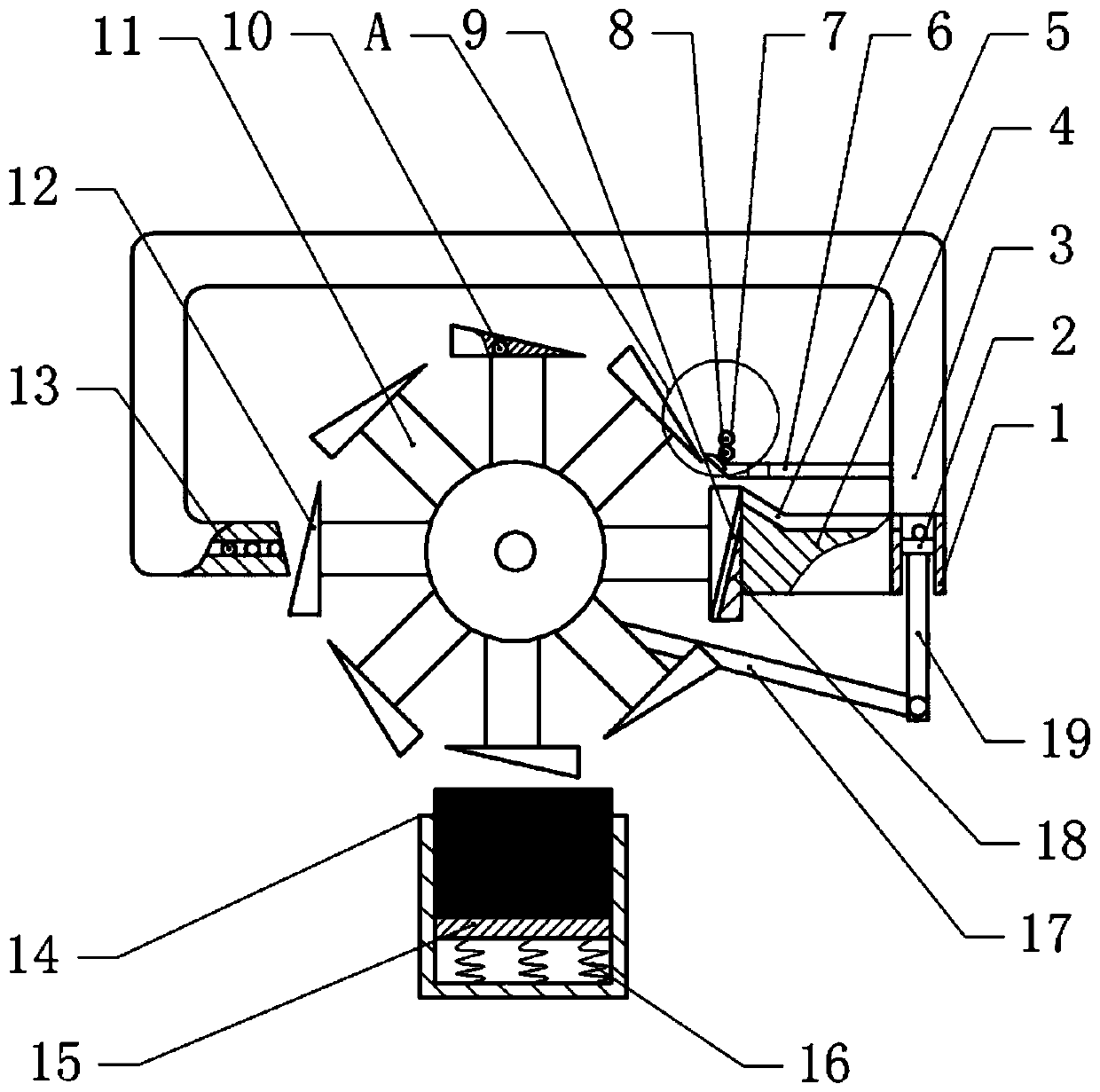

[0027] A sorting device for printing, basically as attached figure 1 And attached figure 2 As shown, it includes a frame, on which a driving part is fixed by fastening bolts, and the driving part is any one of a servo motor or a stepping motor, and the stepping motor is selected in this embodiment. A driving block is fixed on the output shaft of the driving part, and the driving block is any one of a circle or a square, and the present embodiment selects a circle.

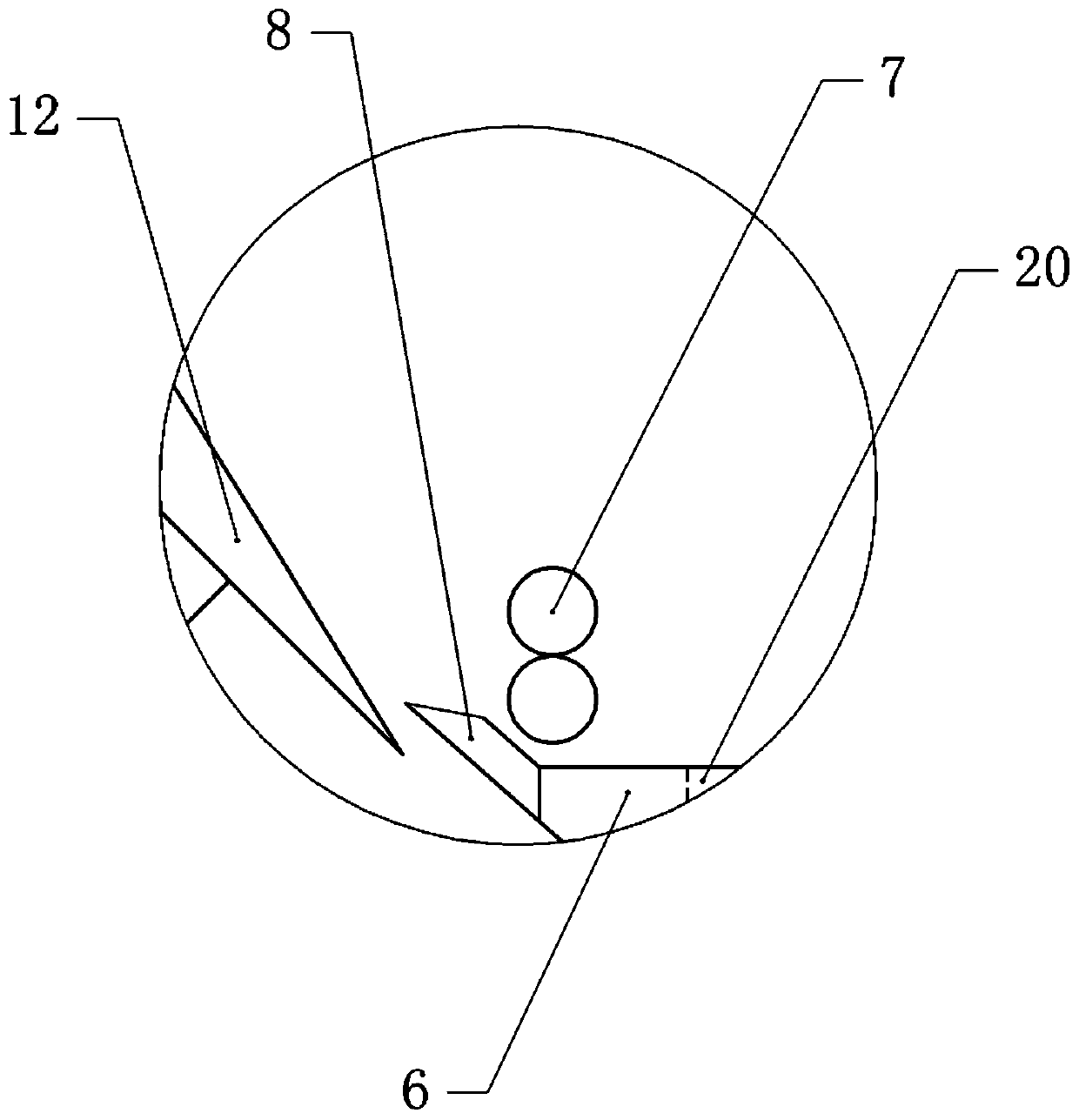

[0028] The outer periphery of the drive block is evenly fixed with a fixed rod 11, and the fixed rod 11 is bonded with an adsorption block 12. The adsorption block 12 is made of rubber material or glass material. The present embodiment is made of rubber material. The adsorption block 12 It is wedge-shaped, and the adsorption block 12 is provided with a cavity, and the main magnet 10 is fixed in the cavity. The right side of the driving block is provided with a connecting piece fixed on the frame, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com