Metal high cycle cryogenic treatment process and automatic cryogenic treatment system

A cryogenic treatment and processing system technology, applied in the field of materials, can solve the problems of inability to strengthen bar metal structural parts, difficulty in controlling material interface oxidation, poor room temperature deformation ability, etc., to achieve low cost, time saving, low energy consumption, and labor load small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

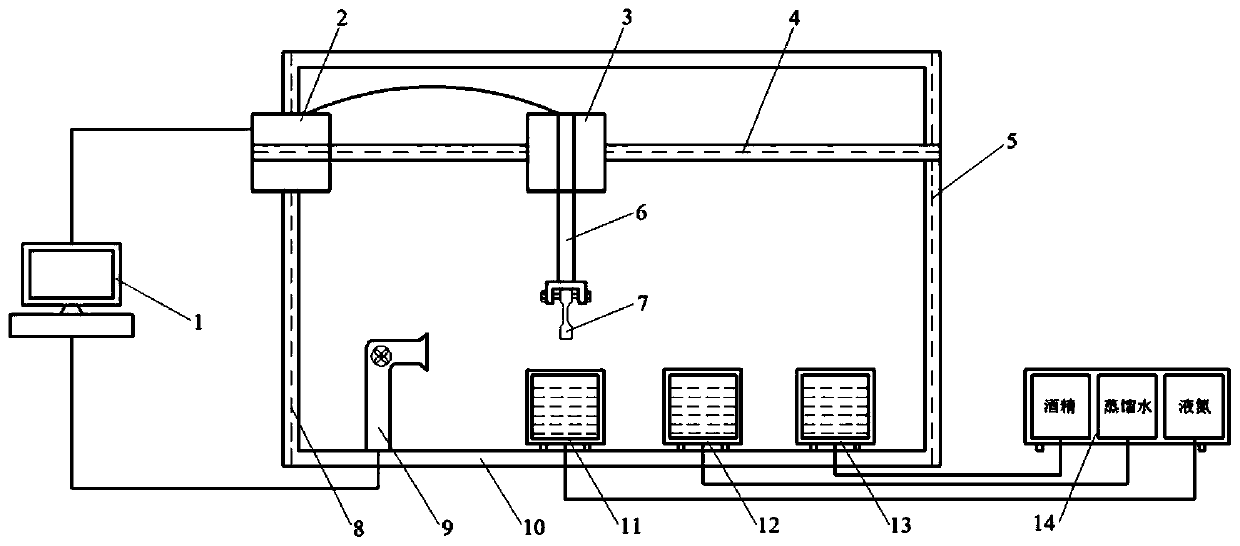

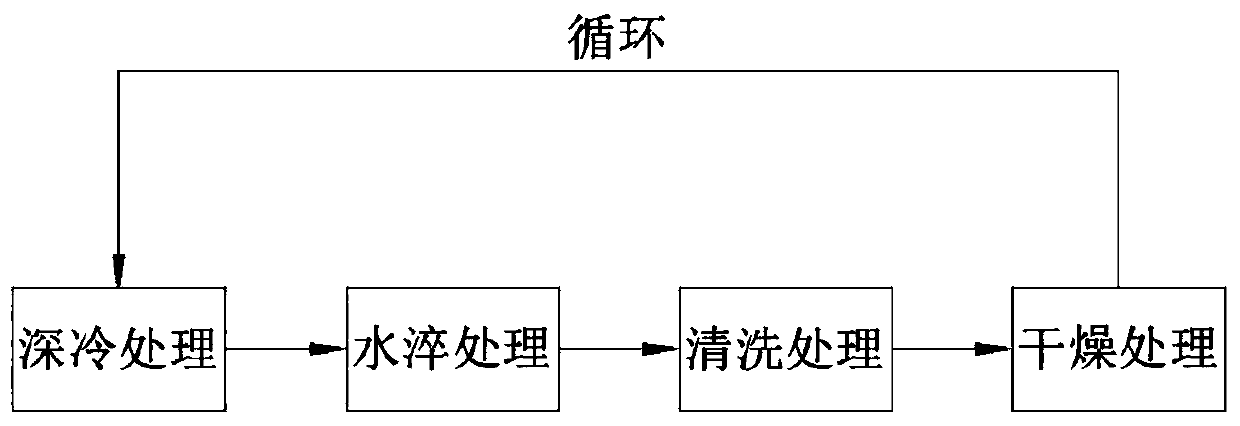

[0049] (1) 6061 aluminum alloy was selected as the experimental material, and the aluminum alloy was subjected to solution treatment at 480°C for 2 hours in a vacuum tube furnace. pass figure 1 The bottom clamping end of the sample connecting rod 6 in the sample clamps the processed 6061 aluminum alloy sample firmly to ensure that the sample does not loosen during the subsequent cyclic cryogenic treatment.

[0050] (2) pass figure 1 The controller programmed by the software controls the movement of the horizontal stepping motor 3 on the horizontal guide rail 4, and moves the sample directly above the cryogenic box 11, and the moving speed of the horizontal stepping motor 3 is set to 0.2m / s Then control the movement of the longitudinal stepping motor 2 on the longitudinal guide rail, the moving speed of the longitudinal stepping motor 2 is set to 0.1m / s, and the whole sample is placed in the cryogenic treatment box to ensure that the cryogenic medium is completely immersed in ...

Embodiment 2

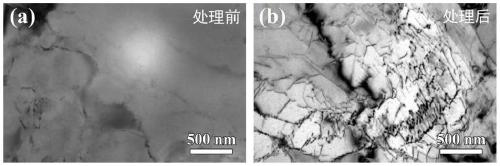

[0058] (1) Select 316L stainless steel as the experimental material, Figure 5 (a) is the metallographic diagram of the original 316L stainless steel sample before treatment. The structure is mainly uniformly distributed austenite, accompanied by a small amount of annealing twins, and the average grain size is about 30 μm. pass figure 1 The clamping end at the bottom of the sample connecting rod in the sample clamps the processed 316L stainless steel sample firmly to ensure that the sample does not loosen during the subsequent cyclic cryogenic treatment.

[0059] (2) pass figure 1 The software program of the computer control system in the computer controls the movement of the horizontal stepping motor on the horizontal guide rail, moves the sample to the top of the cryogenic box, and sets the moving speed of the horizontal stepping motor to 0.2m / s; then controls the vertical stepping Enter the movement of the motor on the longitudinal guide rail, set the moving speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com