Spring and grid combined cushion seismic reduction device applicable to emergency rescue and disaster relief steel shed tunnels

A shock-absorbing device and spring buffering technology, which is applied in construction, protective equipment, etc., can solve the problems of large self-consumables and poor buffer energy consumption performance, and achieve rapid construction, improve the protection energy level of sheds and caves, and reduce impact effects force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

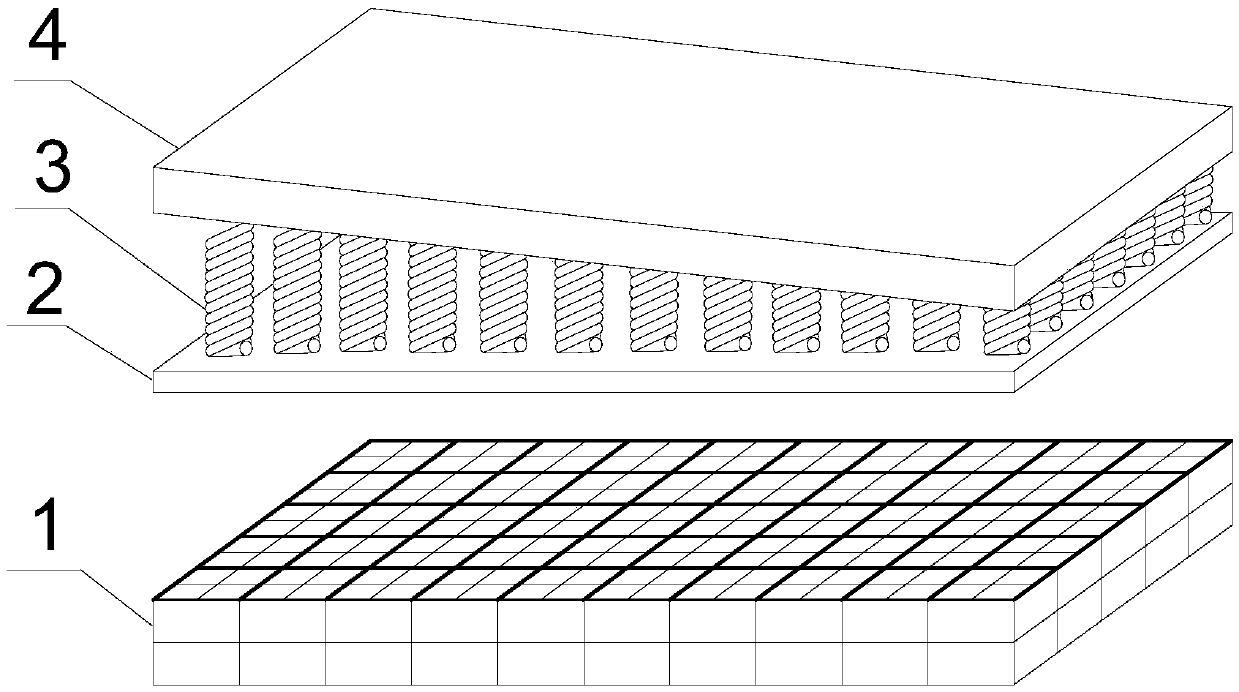

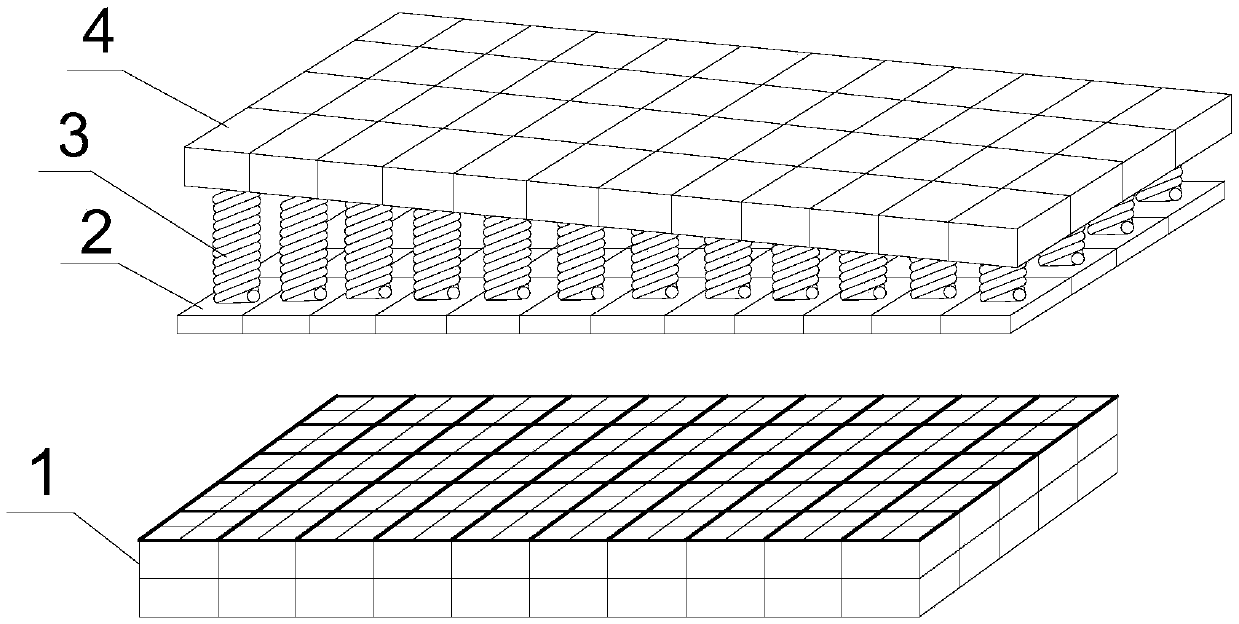

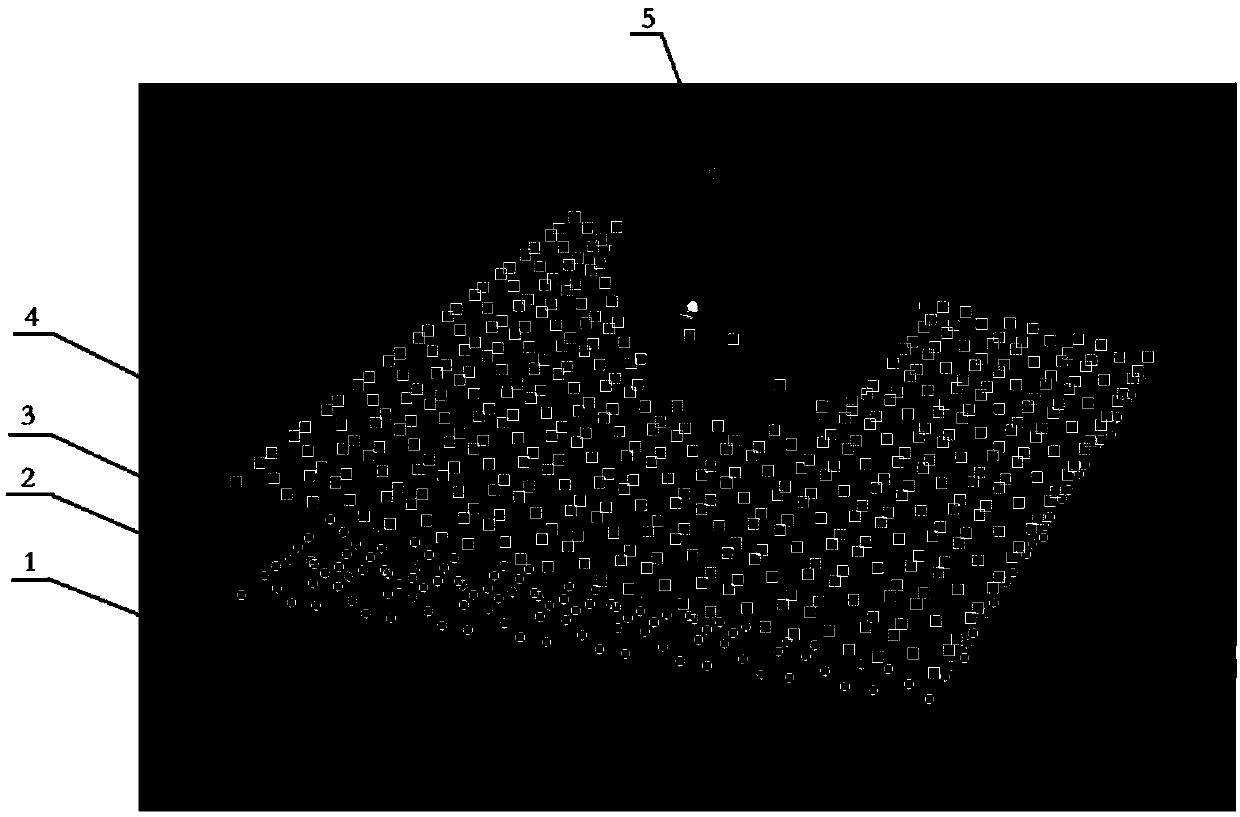

[0043] This embodiment provides a spring-grid combined buffering and shock-absorbing device suitable for emergency rescue and disaster relief steel shed holes, which is composed of two layers of a grid layer 1 and a spring buffer layer, and the grids are laid on the top of the steel shed hole frame from bottom to top in sequence Layer 1 and spring buffer layer; grid layer 1 includes N layers of grids stacked in sequence, N is a positive integer greater than or equal to 1, according to different protection levels, in this embodiment, 2 to 3 layers of grids are selected to be laid ; The spring buffer layer includes the first steel plate layer, several columnar springs 3 and the second steel plate layer from bottom to top.

Embodiment 2

[0045] Further improvement on the basis of Embodiment 1, each layer of grid is composed of multiple cuboid thin-walled boxes spliced together, and each thin-walled box is divided into a plurality of square small grids by partitions; the thin-walled box The radial section has a rectangular structure, preferably a square structure. The axial bottom end of the thin-walled box is in contact with the top of the steel shed tunnel frame, and the axial top is in contact with the axial bottom end of the thin-walled box in the upper grid layer 1 or the first steel plate 2 contacts.

[0046] As a preferred solution, the thin-walled box can be made of aluminum, the dimensions of the thin-walled box are 1m×1m×0.5m, and the grid of the grid layer 1 is filled with polystyrene energy-absorbing buffer material.

Embodiment 3

[0048] Further improvement on the basis of Example 2, the first steel plate layer adopts a whole first steel plate 2, and the second steel plate layer adopts a whole second steel plate 4; the first steel plate 2 and the second steel plate 4 are arranged between A plurality of columnar springs 3 are evenly distributed, the bottom of the columnar springs 3 can be fixed on the upper surface of the first steel plate 2 with existing connecting plates and bolts, and the top of the columnar springs 3 can be fixed with existing connecting plates and bolts Be fixed on the lower surface on the second steel plate 4. A plurality of columnar springs 3 are arranged between the upper surface of the first steel plate 2 and the lower surface of the second steel plate 4 at a slope ratio of 1:5, and the second steel plate 4 is laid on the top of the columnar springs 3 at the same slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com