Plunger piston and oil and gas well structure

A plunger and structure technology, applied in the field of natural gas and oil exploitation, can solve the problems of plunger resistance and the inability of the plunger to descend, and achieve the effect of reducing descending resistance and improving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

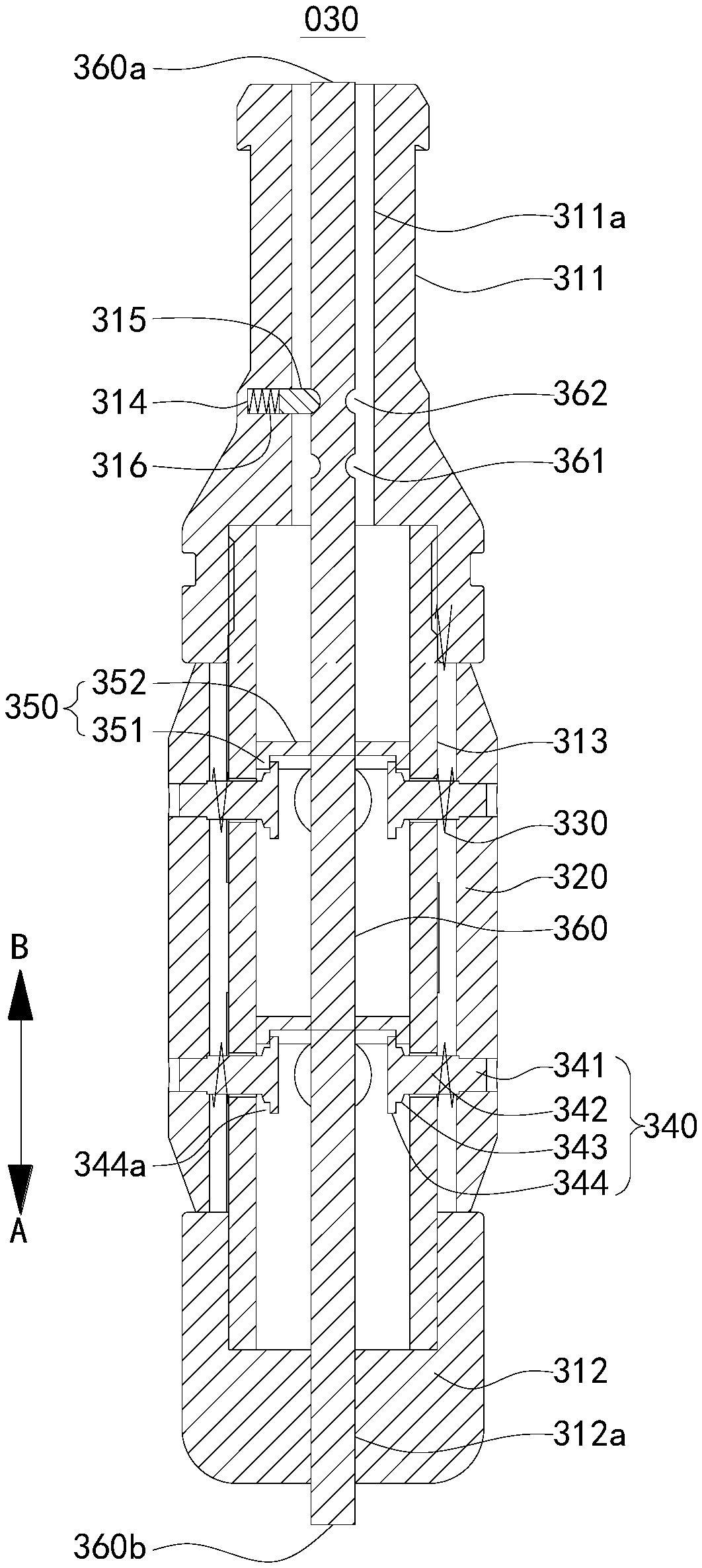

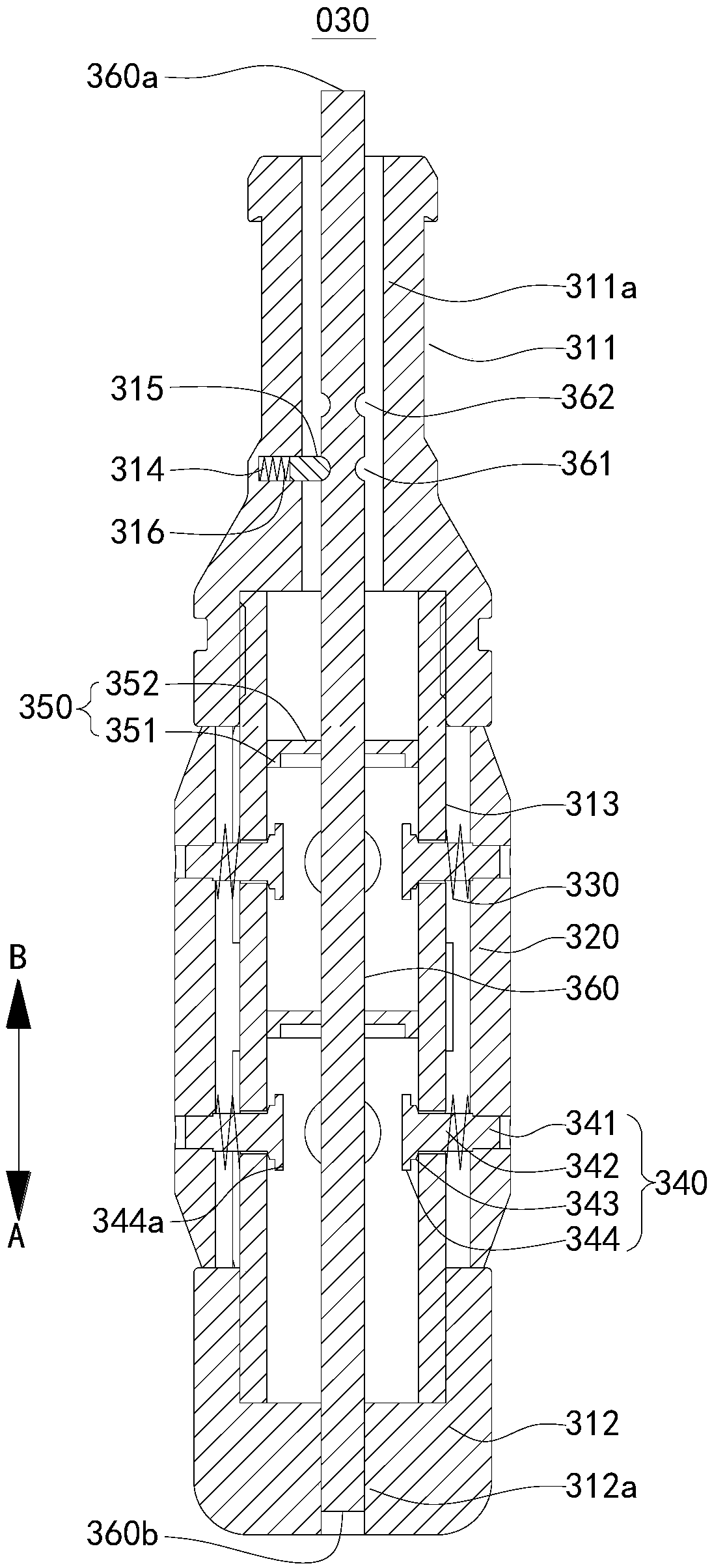

[0039] figure 1 A schematic diagram of the structure of the locking member 350 in the plunger 030 provided in this embodiment when it is in the unlocked position; figure 2 This embodiment provides a schematic diagram of the structure of the locking member 350 in the plunger 030 when it is in the locked position. The plunger 030 includes a core tube 310 , a plurality of sealing pieces 320 , an elastic member 330 , a guide post 340 , a locking member 350 and an actuating part 360 .

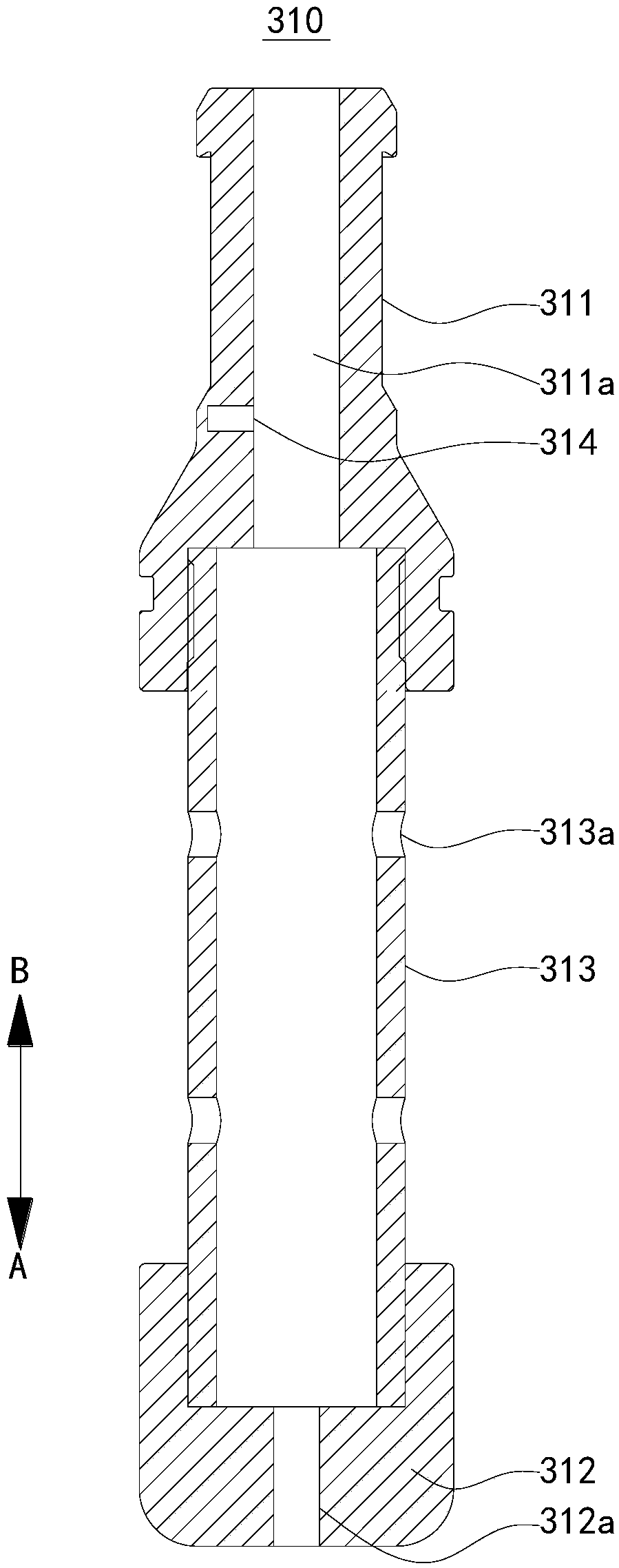

[0040] image 3 A schematic structural view of the core tube 310 of the plunger 030 provided in this embodiment. In this embodiment, the core tube 310 is a tubular member extending along the AB direction. The core tube 310 includes a first end 311 , a second end 312 and a tube body 313 . Two ends of the core tube 310 are respectively inserted into the first end 311 and the second end 312 , and screwed to the first end 311 and the second end 312 . A first through hole 311 a extending along the ...

Embodiment 2

[0051] Figure 4 In the plunger 030 provided for this embodiment, the state diagram when the locking member 350 is in the locking position; Figure 5 In the plunger 030 provided for this embodiment, a state diagram of the lock member 350 at the unlocked position. Please refer to Figure 4 and Figure 5 , the plunger 030 provided in this embodiment is basically the same as that in Embodiment 1, the main difference is that the first joint part 361, the second joint part and the third joint part 362 in this embodiment 1 are triggered by the holding mechanism 010 replace.

[0052] In this embodiment, the actuating part 360 includes a first part 363 and a second part 364 which are independent from each other. The first portion 363 and the second portion 364 are arranged at intervals along the AB direction. The end of the first part 363 away from the second part 364 is the first end 360a; the end of the second part 364 away from the first part 363 is the second end 360b. The fir...

Embodiment 3

[0060] Figure 9 A schematic structural diagram of the oil and gas well structure 01 provided in this embodiment. Please refer to Figure 9 , the oil and gas well structure 01 provided in this embodiment includes the plunger 030 described in Embodiment 1 or Embodiment 2. The oil and gas well structure 01 also includes a wellhead pipeline 11 located on the ground, and a wellway 12 arranged below the ground and communicating with the wellhead pipeline 11 . An upper impact part 13 is arranged on the top of the wellhead pipeline 11 , and a lower impact part 14 is arranged on the bottom of the hoistway 12 . The inner diameter of the wellhead pipeline 11 is smaller than the inner diameter of the shaft 12 . The plunger 030 can go down from the top of the wellhead pipeline 11 to the bottom of the wellhead pipeline 12 , and the plunger 030 can also go up from the bottom of the wellhead pipeline 12 to the top of the wellhead pipeline 11 .

[0061] After the plunger 030 goes up into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com