Adjustable stop valve

A cut-off valve, adjustable technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of shortened service life, small flow adjustment accuracy, and easy wear of the sealing surface, so as to reduce the wear rate and improve the service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

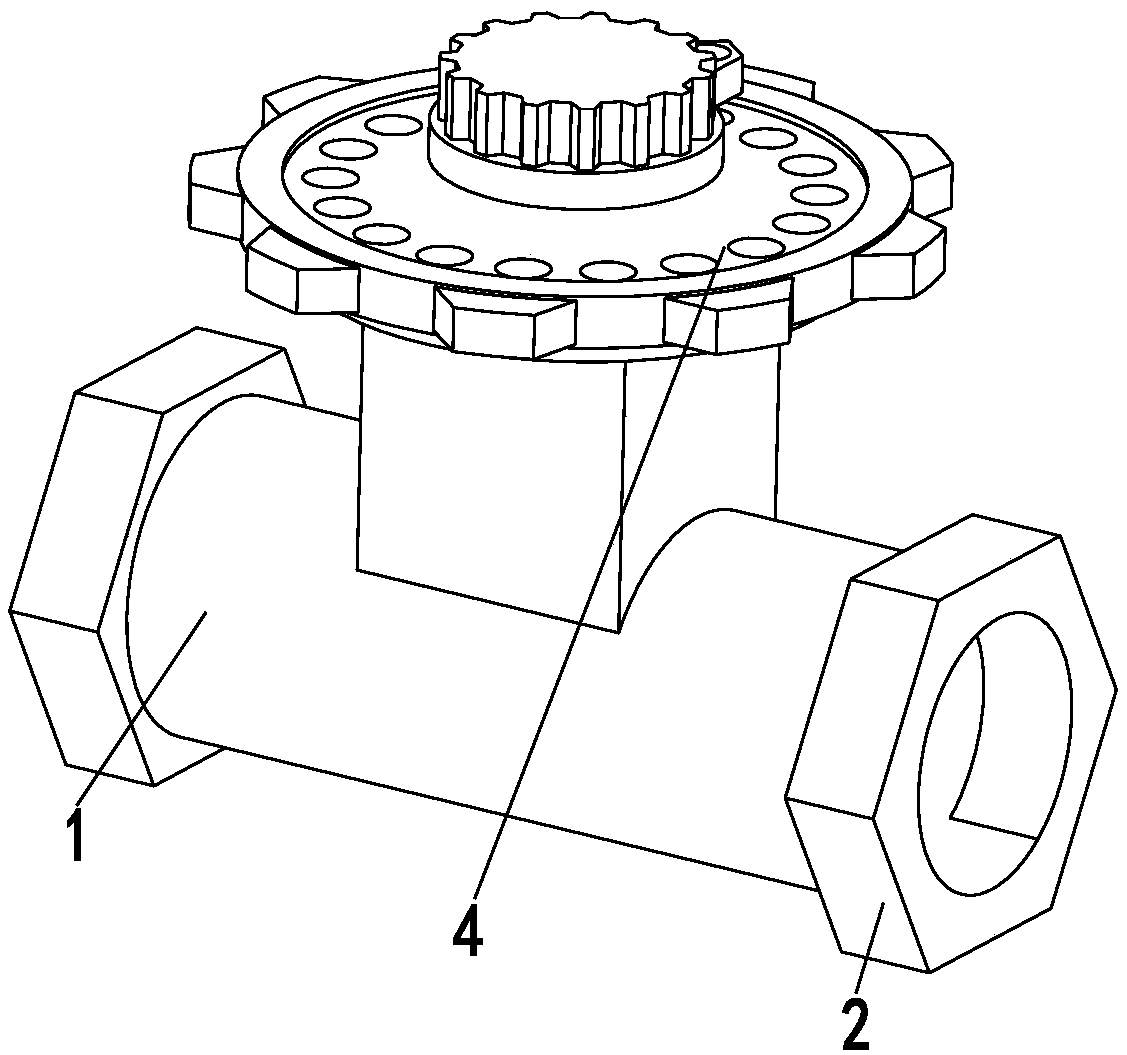

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 5 , to further elaborate the present invention.

[0027] An adjustable cut-off valve, comprising a valve body 1, a connecting nut 2, an adjustment mechanism 3 and a control mechanism 4, the valve body 1 is a hollow cylinder structure with openings on the left and right ends, the left and right ends of the valve body 1 are symmetrically installed with connection Nut 2, a square through hole is opened in the middle of the valve body 1, and an adjustment mechanism 3 is arranged in the square through hole, and the upper end of the adjustment mechanism 3 is connected with the control mechanism 4; wherein:

[0028] The adjustment mechanism 3 includes an adjustment cylinder 31, an adjustment plate 32, a driven bevel gear 33, a driving bevel gear 34 and a connecting frame 35. The adjustment cylinder 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com