Matching drying equipment for dyeing clothing cloth

A technology for drying equipment and fabrics, which is applied in drying, dryers, lighting and heating equipment, etc. It can solve the problems of low drying efficiency, inconvenient threading operation, and insufficient heating of fabrics, etc., and achieves sufficient heating and improved Drying effect, convenient and fast winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

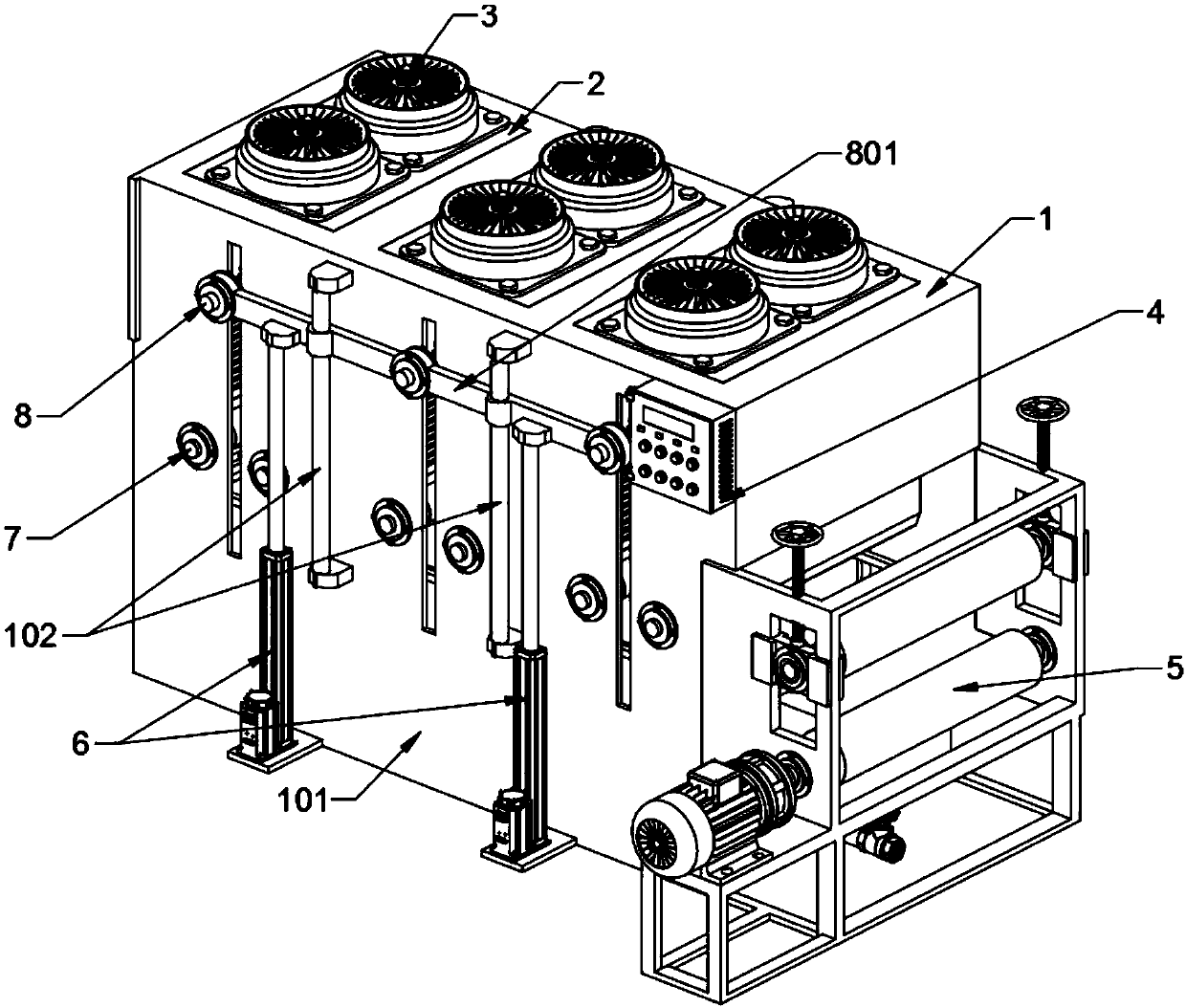

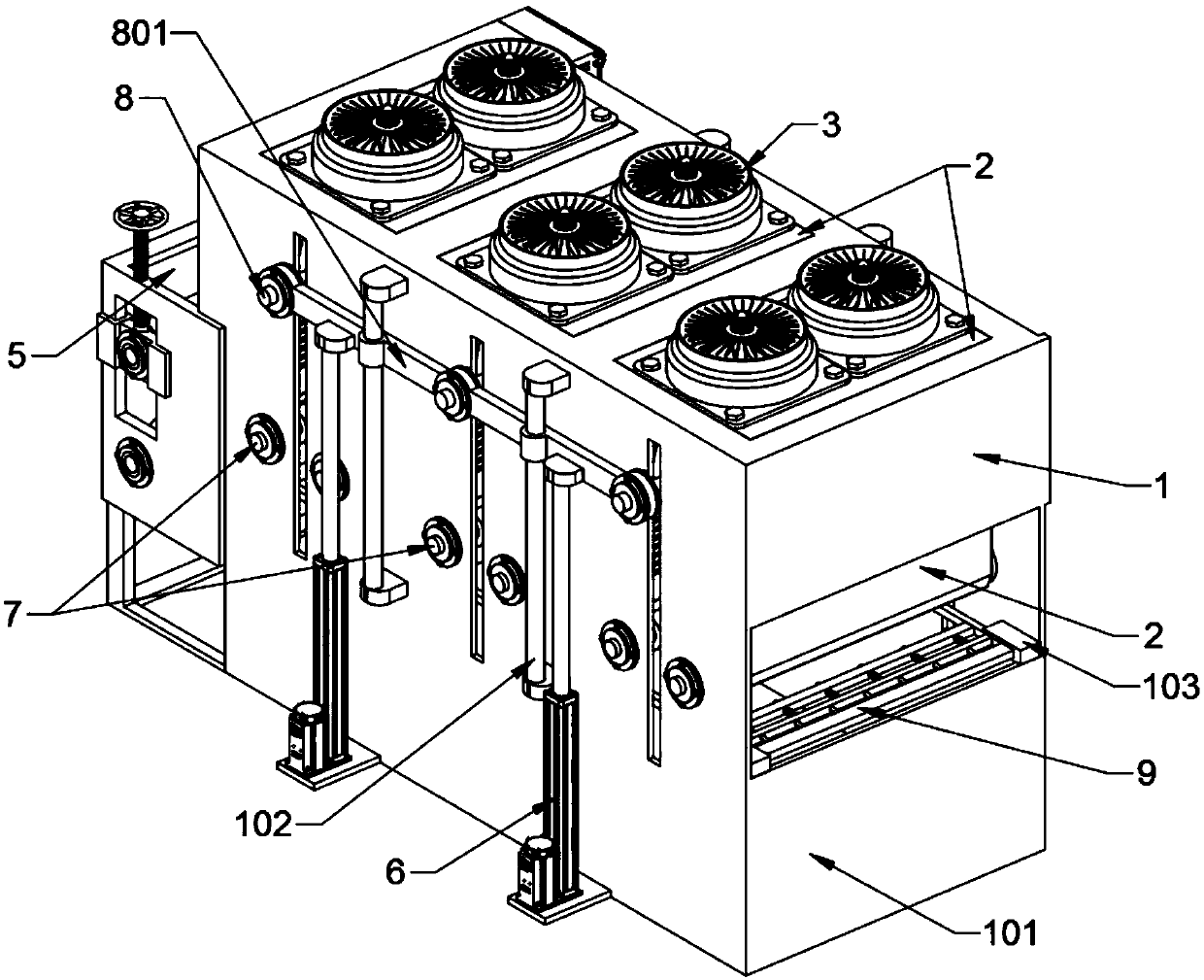

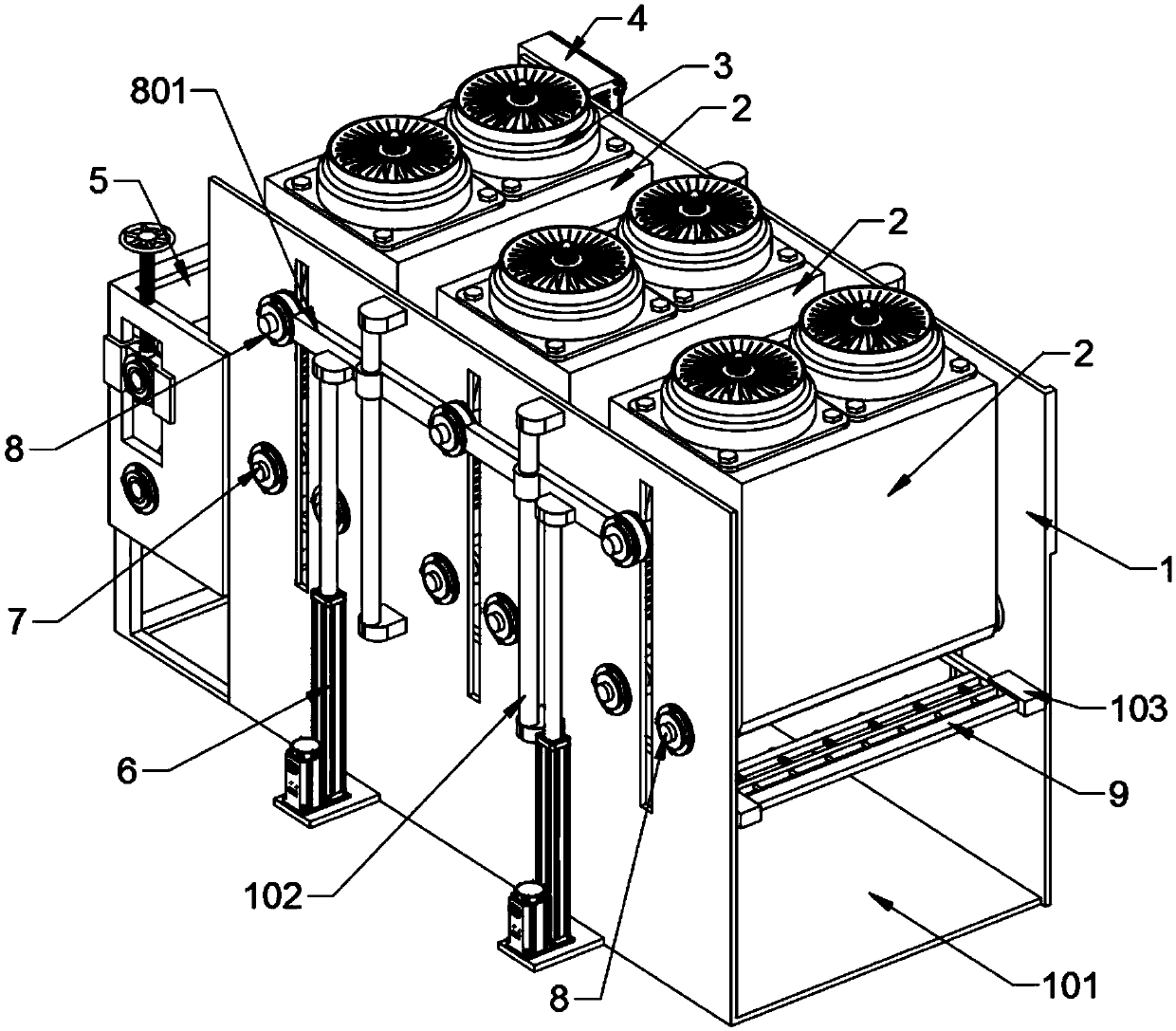

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The present invention provides a matching drying equipment for clothing fabric dyeing, comprising a drying box 1, a water receiving tank 101, a positioning rod 102, a chute 103, a hot air box 2, an electric heating fan 3, a control electric box 4, a pressure roller 5, Electric push rod 6, lower guide roller 7, upper guide roller 8, guide roller mounting plate 801, cloth threading frame 9, positioning plate 901 and top plate 902; , and a group of pressure rollers 5 driven by a motor are supported and welded on the front opening; three downwardly arranged hot air boxes 2 are arranged and welded on the top plate of the drying box 1, and the upper front end of the left outer wall is welded and installed There is a control electric box 4, and the four contactors inside the control electric box 4 are respectively connected with six electric heaters 3, four electric push rods 6 and roller motors for electrical control;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com