An Intelligent Control Method of Sintering Endpoint to Improve Carbon Efficiency

A technology of sintering end point and intelligent control, which is applied in the direction of furnace control device, furnace, furnace type, etc., to achieve the effect of improving carbon efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

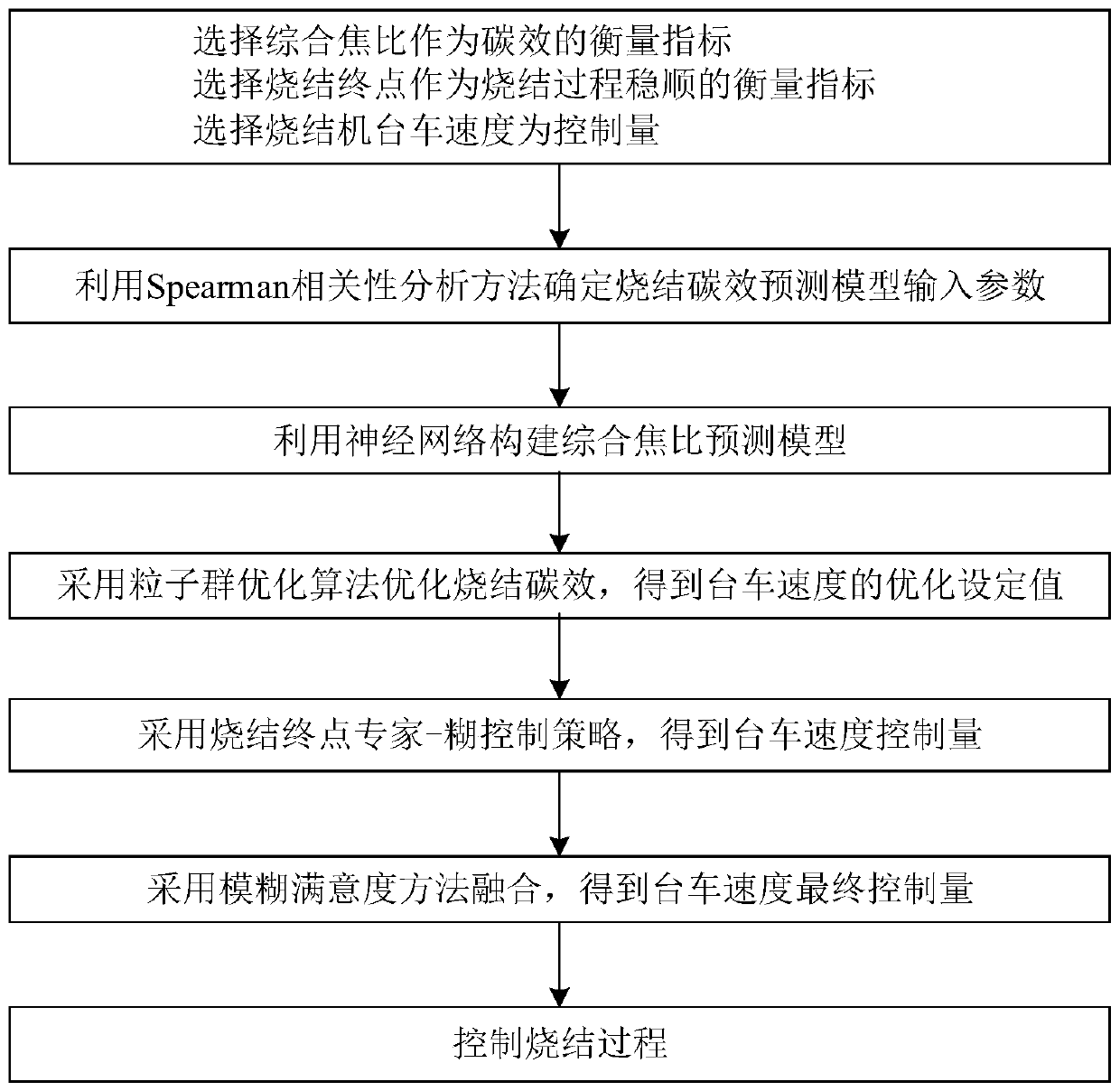

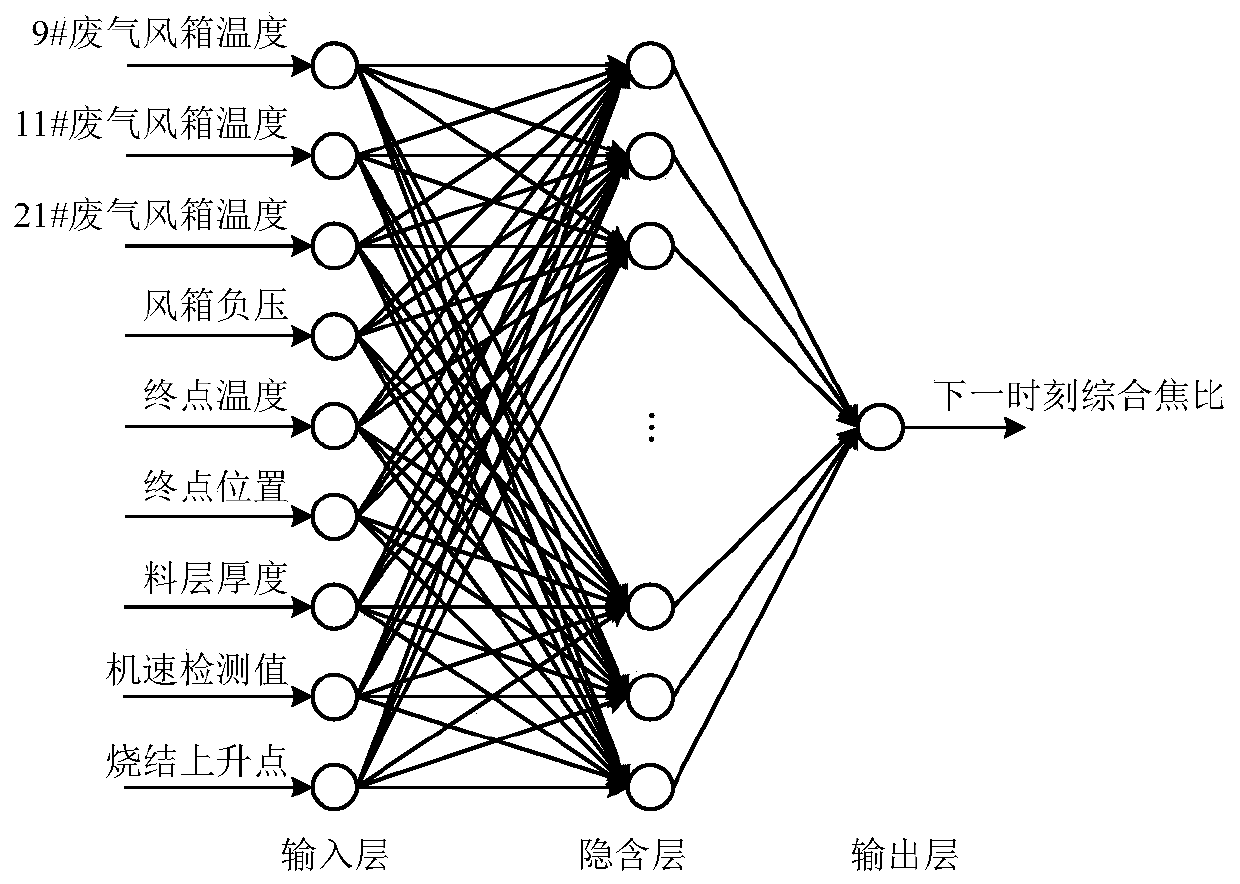

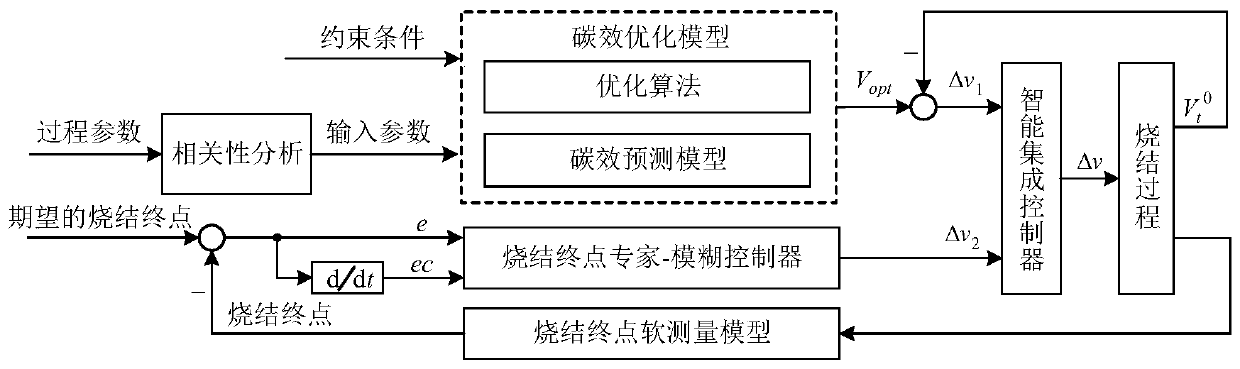

[0066] An intelligent control method of sintering end point to improve carbon efficiency, such as figure 1 shown, including:

[0067] Step 1: Select the comprehensive coke ratio as the measure of carbon efficiency, the sintering end point as the measure of the smoothness of the sintering process, and the speed of the sintering machine trolley as the control amount.

[0068] 1-1. Select the comprehensive coke ratio as the carbon efficiency indicator of the sintering process, which is the amount of coke consumed by the production unit of sinter, and give the calculation formula of the comprehensive coke ratio as follows:

[0069]

[0070] Among them, η represents comprehensive coke ratio (kg / t), P C Indicates the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com