Card-making substrate, preparation method thereof and IC card or electronic tag containing card-making substrate

An electronic label, card substrate technology, applied in chemical instruments and methods, cards, manufacturing tools, etc., can solve the problems of greatly reduced apparent brightness of IC cards, poor practical application effects, violations, etc., so as not to damage the appearance effect, Effects of reduced gloss, long read and write distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

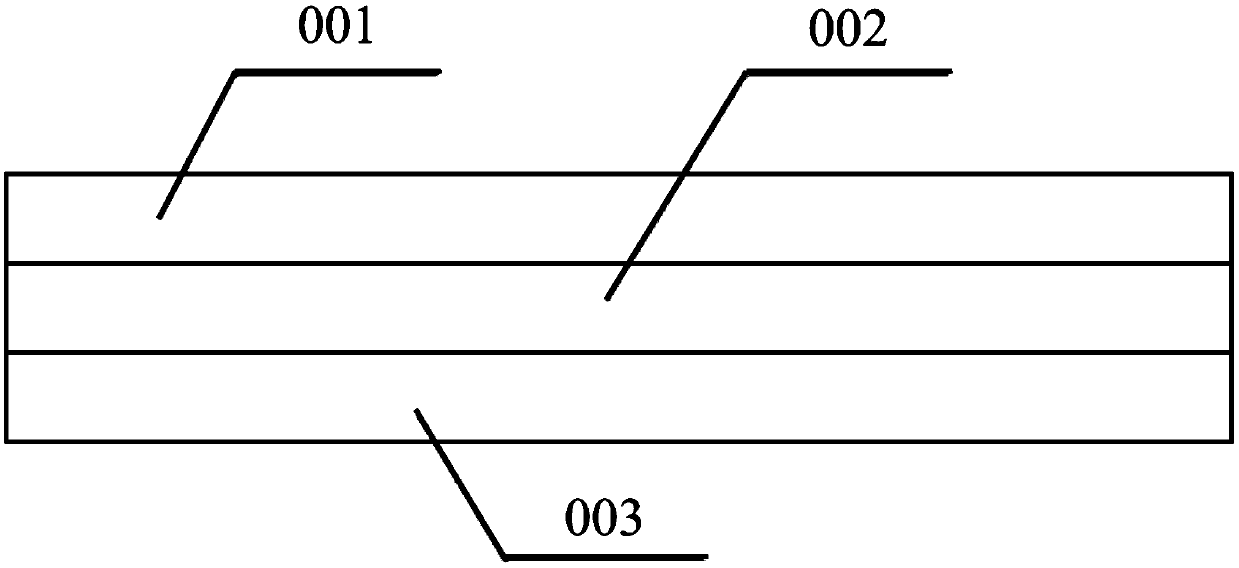

[0059] Prepare the laser card substrate 1 through the following steps:

[0060] In step (1), one layer of adhesive glue with a thickness of 30 μm is coated on the side of the aluminum-coated film containing the aluminum film. Substrate layer 003 is laminated and cut to obtain a pretreated substrate;

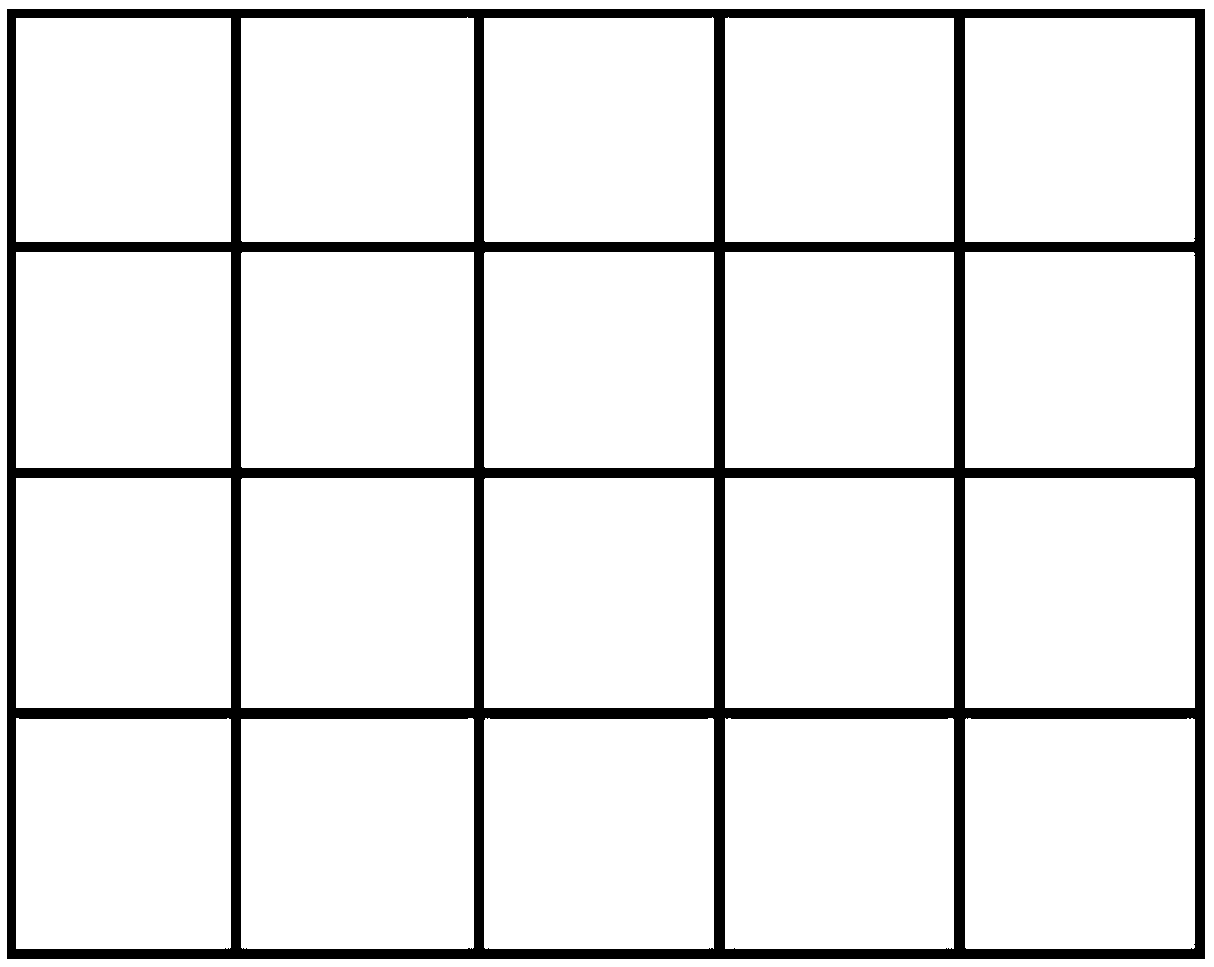

[0061] Step (2), carry out laser etching process to the surface of the aluminized film layer in the pretreatment substrate obtained in step (1), form continuous scratches on the surface of the aluminum film, the width of the scratches is 0.05mm, and the depth is 55nm, the scratches divide the aluminum film of the aluminized film into 20 non-connected square areas with a side length of 1 mm to obtain the laser card substrate.

[0062] Wherein, the aluminized film described in the step (1) is a PET film coated with an aluminum film on the surface, the thickness of the PET film is 0.08mm, and the thickness of the aluminum film is 35nm.

[0063] The substrate layer 003 described in...

Embodiment 2

[0068] Prepare the laser card substrate 2 through the following steps:

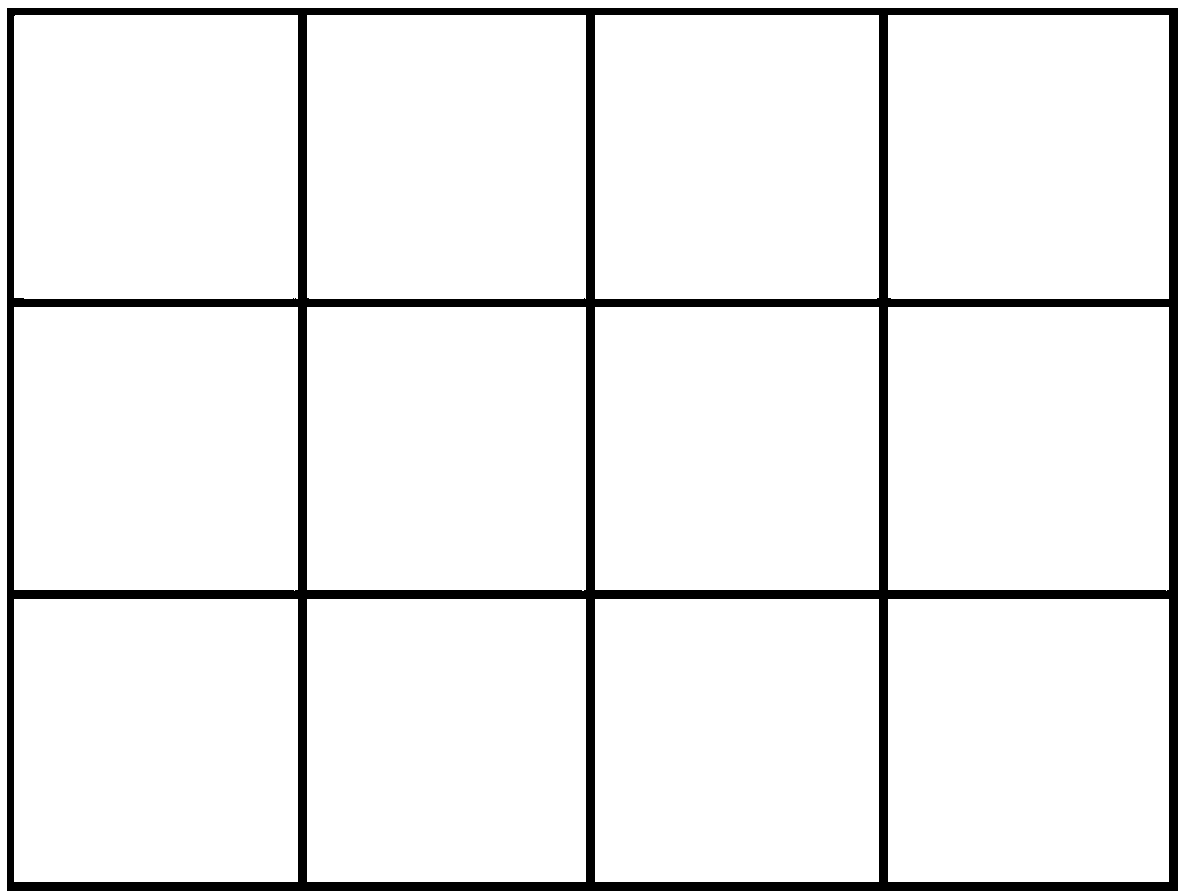

[0069] The only difference from Example 1 is that the scratches divide the aluminum film of the aluminized film into 12 non-connected square areas with a side length of 1.29 mm.

[0070] Scratch makes the aluminum film surface in the aluminized film layer of the laser card substrate 2 that embodiment 2 obtains has such as image 3 pattern shown.

Embodiment 3

[0072] Prepare the laser card substrate 3 through the following steps:

[0073] The only difference from Example 1 is that the scratches divide the aluminum film of the aluminized film into 8 unconnected right-angled triangular areas with side lengths of 2 mm, 2.5 mm and 3.2 mm, respectively.

[0074] Scratch makes the aluminum film surface in the aluminized film layer of the laser card substrate 3 that embodiment 3 obtains has such as Figure 4 pattern shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com