Paper feeding mechanism for paper wrapping machine

A technology of paper feeding mechanism and wrapping machine, applied in the direction of transportation and packaging, object supply, positioning objects, etc., can solve the problems of reducing work efficiency, process influence, operator trouble, etc., to improve production efficiency, improve quality, avoid The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

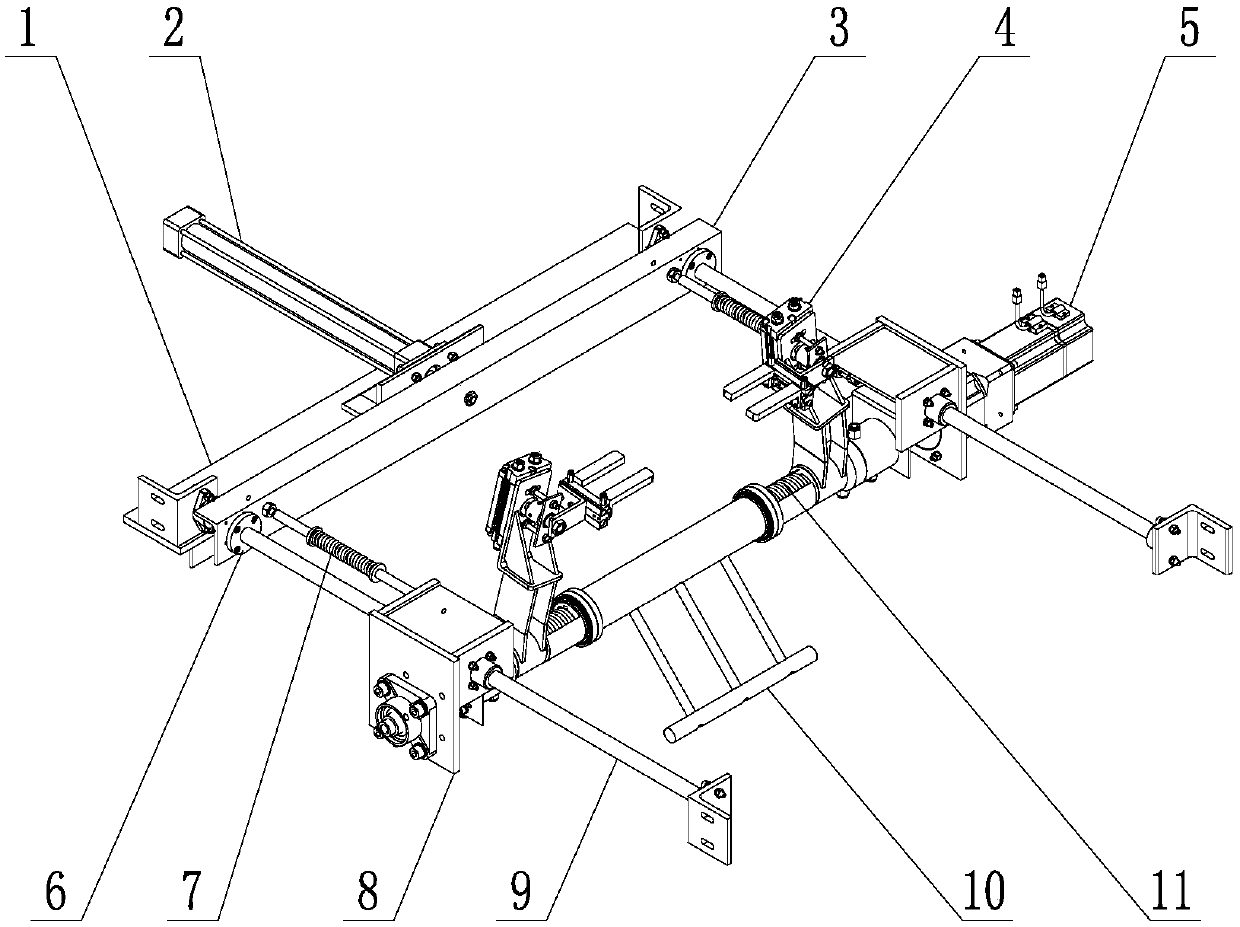

[0023] Embodiment 1: a kind of paper feeding mechanism for wrapping machine, see figure 1 As shown, it includes the driving device 2 of the paper feeding mechanism and the guiding device. Both the driving device 2 and the guiding device of the paper feeding mechanism are fixedly installed on the frame 1 of the wrapping machine. Connected, the deviation correction mechanism is also fixedly connected with the telescopic end of the paper feeding mechanism driving device 2, and the paper feeding mechanism driving device 2 is used to drive the deviation correction mechanism to move back and forth along the guide device.

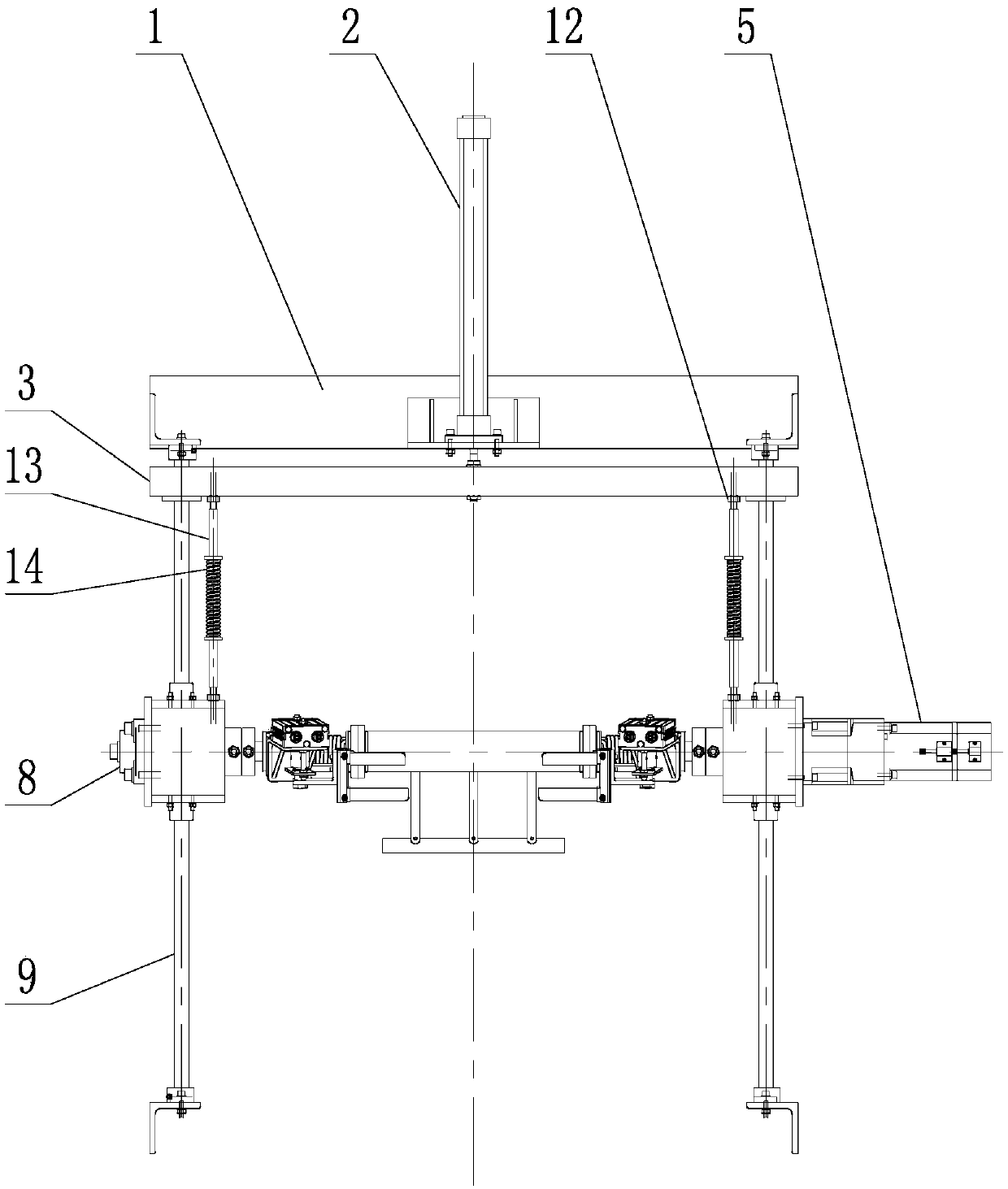

[0024] see figure 2 As shown, the correction mechanism includes a buffer beam 3 and two supports 8 all installed on the guide device, each support 8 is connected to one side of the buffer beam 3 through a correction assembly 7, and the other side of the buffer beam 3 One side (the side opposite to the installation position of the support) is fixedly connected wi...

Embodiment 2

[0026] Embodiment 2: on the basis of embodiment 1, refer to figure 2 As shown, the deviation correction assembly 7 includes a deviation correction spring 14 and a deviation correction rod 13 , both ends of the deviation correction spring 14 are respectively connected to the buffer beam 3 and the support 8 through the deviation correction rod 13 .

[0027] In the embodiment of the present invention, a deviation correction spring 14 and a deviation correction rod 13 are used to form a deviation correction assembly 7. When there is a deviation in the position of the I-shaped wheel, the deviation correction mechanism and the I-shaped wheel will deflect at the same angle in parallel, resulting in two deviation correction springs 14 Depending on the amount of compression, different tensions are formed on both sides of the paper, which automatically corrects the deviation of the paper feeding path of the paper feeding mechanism.

Embodiment 3

[0028] Embodiment 3: on the basis of embodiment 2, refer to figure 2 As shown, one end of the deviation correction rod 13 is fixedly connected with the deviation correction spring 14, and the other end of the deviation correction rod 13 is provided with an external thread. The distance between seat 8 and buffer beam 3.

[0029] In the embodiment of the present invention, the distance between the two supports 8 and the buffer beam 3 can be precisely adjusted through the adjusting nut 12, so as to reduce the error caused by the inconsistent inelastic deformation of the two correction springs 14 during use , to avoid deviation of the paper feeding path of the paper feeding mechanism, so as to improve the quality of product packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com