Elevator counter weight opposite-arrangement traction mechanism

A traction machine and counterweight technology, which is applied to elevators in buildings, hoists, and lifting equipment in mines, etc., can solve problems such as low safety, slipping, and poor braking reliability, and achieve safety High, avoid skidding, good braking reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

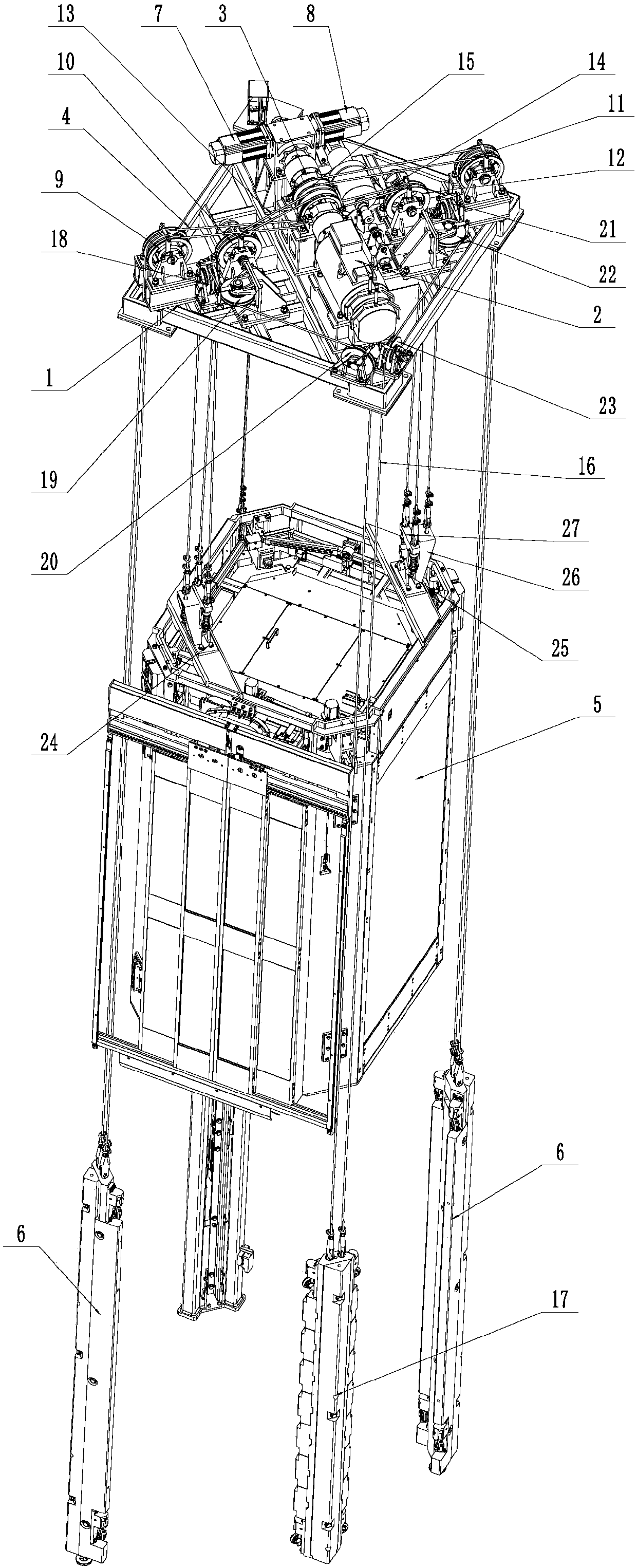

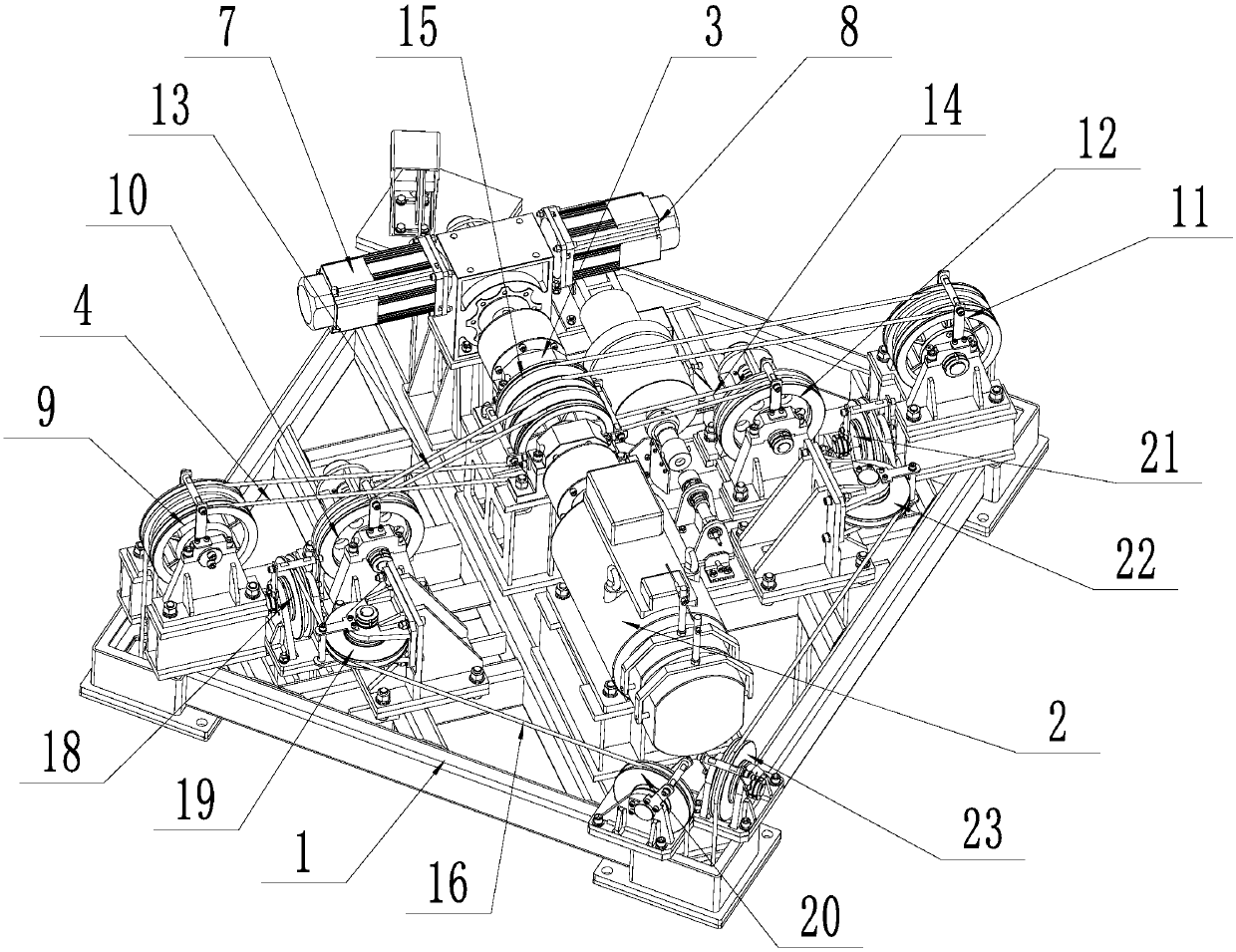

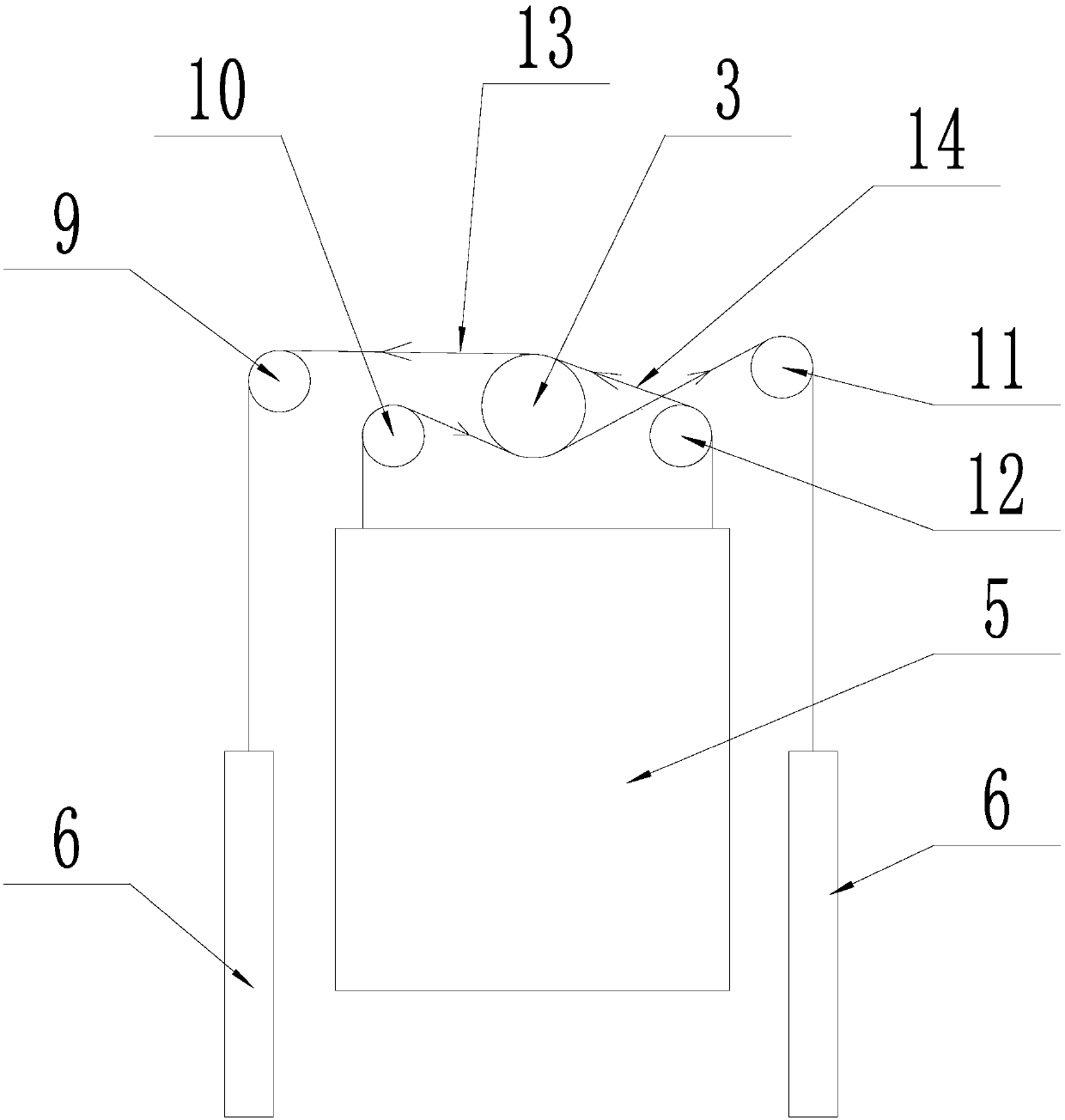

[0022] Embodiment: An elevator counterweight opposing traction mechanism (see attached Figures 1 to 4), including the elevator control system used to control the operation of the elevator and fault detection, the traction machine 2 installed on the installation platform 1 on the top of the elevator shaft to control the elevator up and down, the worm gear device, the synchronization device, and the traction machine connected to the traction wheel 3. Two sets of traction ropes 4 are wound around the traction sheave, and the traction ropes are wound on the traction sheave to form a wrap angle of more than 180 degrees. One end of the traction rope is connected to the car 5, and the other end is connected to a long strip-shaped vertical car. The counterweight of the set car is 6, the counterweight of the two cars is set diagonally, the connection position of the two sets of traction ropes and the car is set diagonally, the traction wheel is coaxially connected to the worm wheel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com