Optical glass, preformed glass member, optical element and optical instrument

A technology of optical glass and weight percentage, applied in optical components, instruments, optics, etc., can solve the problems of difficult production of phosphate system glass, increased production cost, high production cost, etc.

Active Publication Date: 2019-04-23

CDGM OPTICAL GLASS

View PDF16 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with borosilicate glass, phosphate system glass has the following problems: 1) The production difficulty of phosphate system glass is greater than that of borosilicate glass, and the production cost is high; 2) The raw material cost of phosphate system glass is lower than that of borosilicate glass. The raw material cost of salt glass is high; 3) Phosphate glass corrodes (consumes) the platinum utensils used in the production process more than borosilicate glass. Further increase the production cost; 4) Part of the phosphide volatilizes during the production of phosphate glass, which brings potential threats to operators and the environment

Generally speaking, the transmittance of heavy lanthanum flint glass with a refractive index exceeding 1.80 will drop rapidly or even turn black under the condition of non-oxidizing atmosphere, which is a catastrophic problem for production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0094]

[0095] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

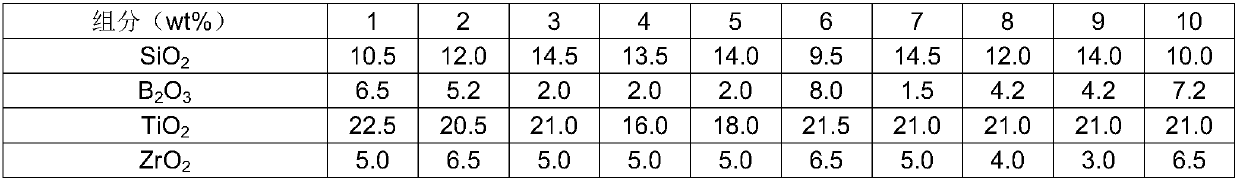

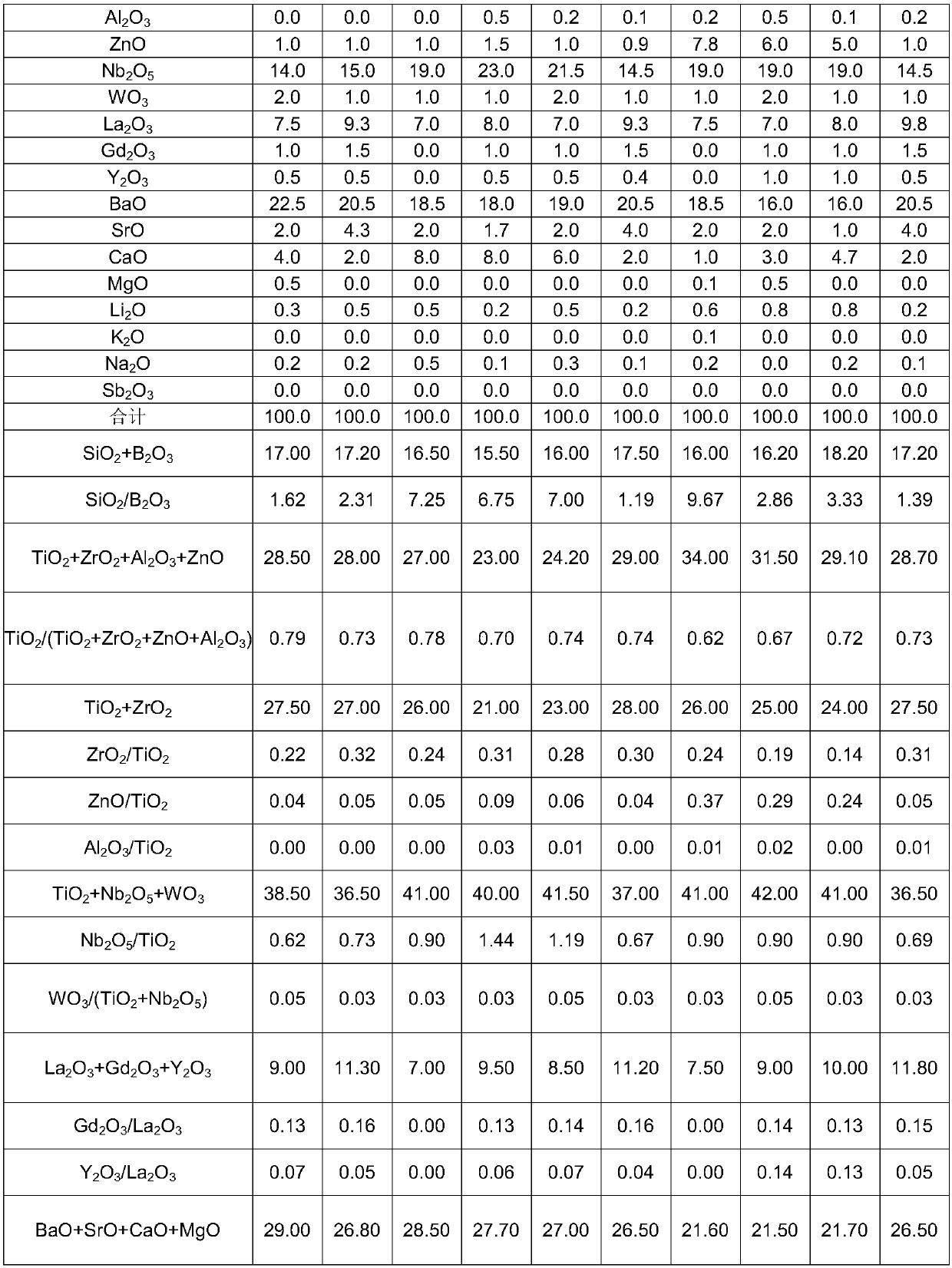

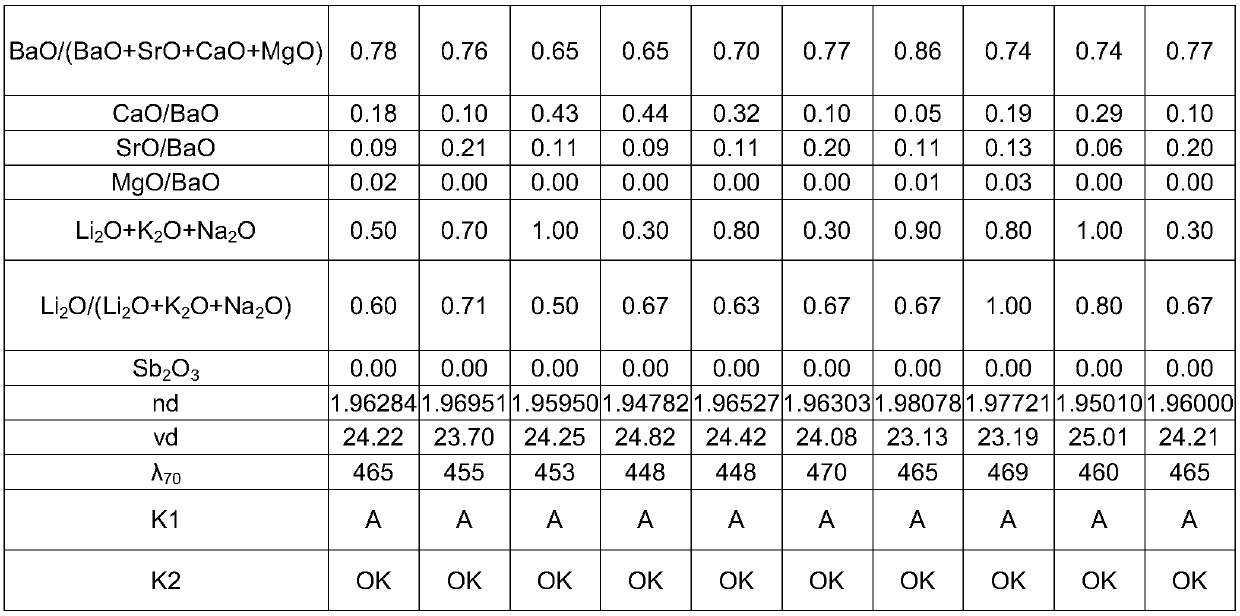

The invention provides an ultrahigh-refractive-index flint glass belonging to a borosilicate system. The ultrahigh-refractive-index flint glass is composed of, by weight percentage, 10-25% of SiO2+B2O3, 15-50% of TiO2+ZrO2+Al2O3+ZnO, 25-60% of TiO2+Nb2O5+WO3 and 14-35% of BaO+SrO+CaO+MgO. Through reasonable composition, under a refractive index of 1.92-2.00 and an abbe number of 20-30, the ultrahigh-refractive-index flint glass achieves excellent transmittance and good devitrification resistance and facilitates production and secondary compression.

Description

technical field [0001] The invention relates to an optical glass, in particular to an ultra-high refractive index flint glass with a refractive index of 1.92-2.00 and an Abbe value of 20-30. Background technique [0002] The glass with a refractive index of 1.92-2.00 and an Abbe number of 20-30 belongs to ultra-high refractive index flint glass. This type of glass has high refractive index and dispersion. When used in conjunction with crown glass, it can effectively eliminate chromatic aberration and The secondary spectrum can effectively shorten the total optical length of the lens and miniaturize the imaging system. Therefore, this optical glass has broad application prospects in future optical designs. [0003] In the prior art, such glass usually adopts P 2 o 5 —Nb 2 o 5 —TiO 2 - RO glass system (R refers to Mg, Ca, Sr, Ba). Compared with borosilicate glass, phosphate system glass has the following problems: 1) The production difficulty of phosphate system glass is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C3/066C03C4/00C03C3/068G02B1/00

CPCC03C3/066C03C3/068C03C4/00G02B1/00

Inventor 毛露路李丹郝良振

Owner CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com