Reclaimed material loading system and reclaimed material loading method for asphalt stirring station

A technology of asphalt mixing plant and recycled materials, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, heating tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc. Long feeding time and other problems can improve production efficiency, prevent damage and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

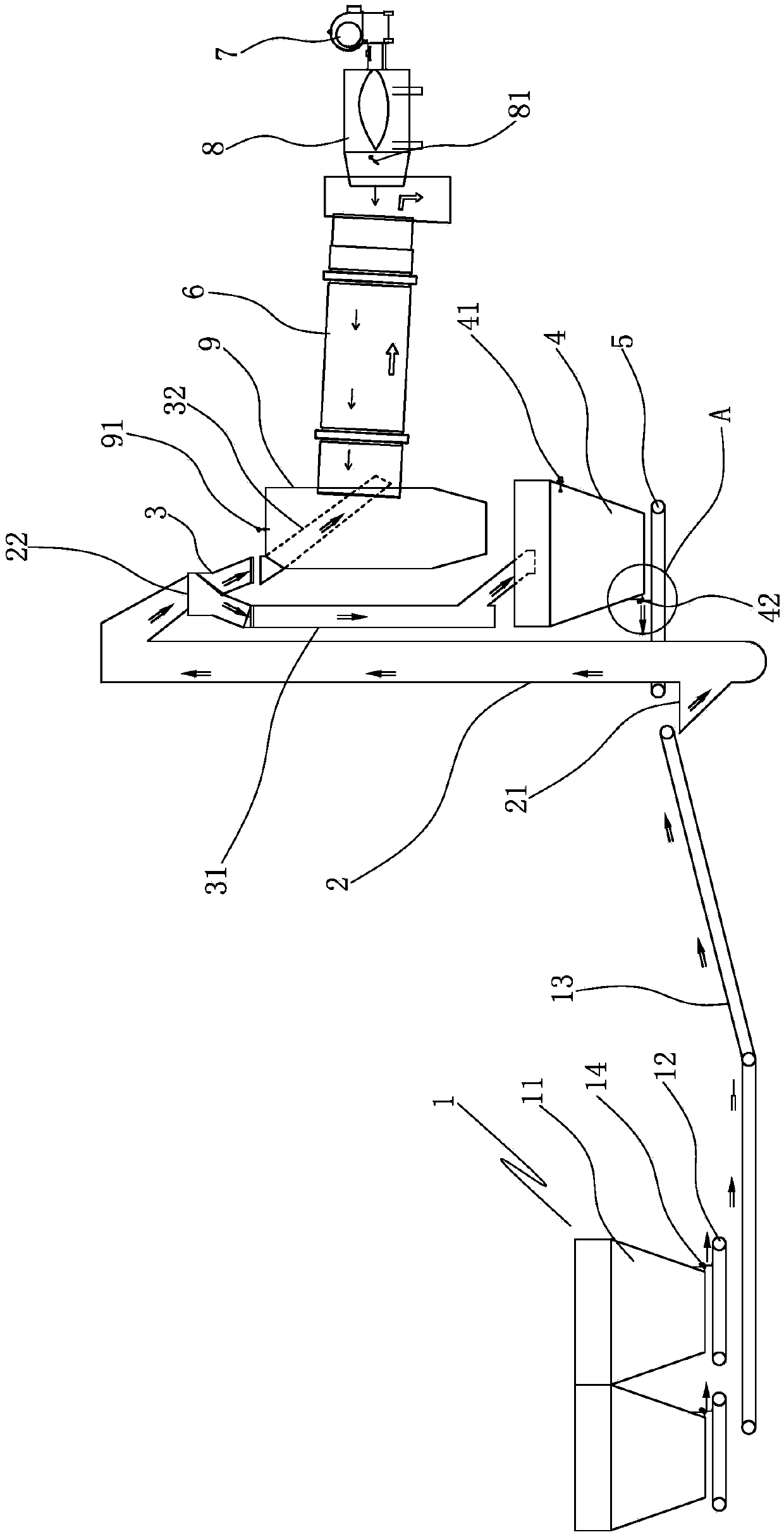

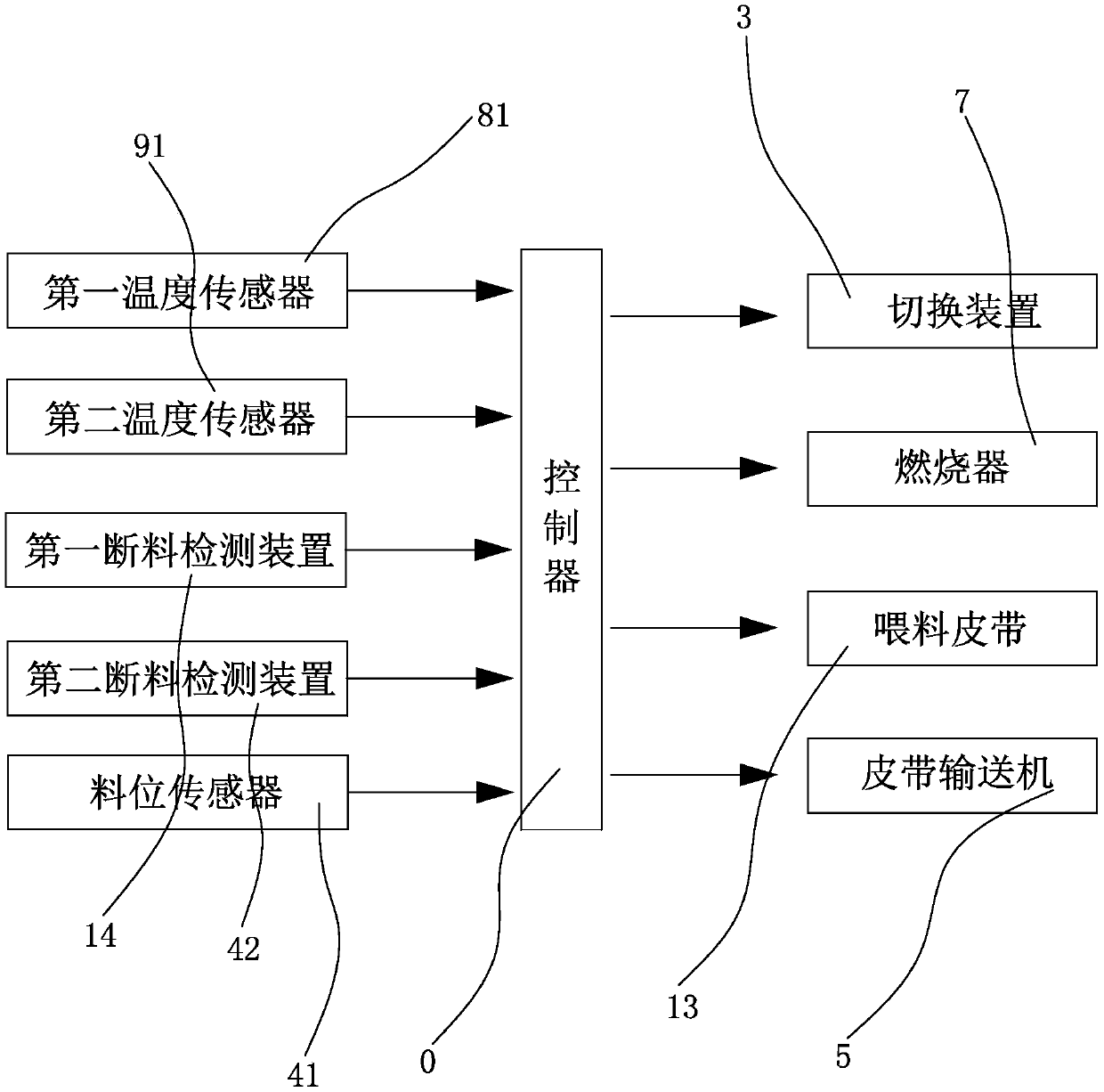

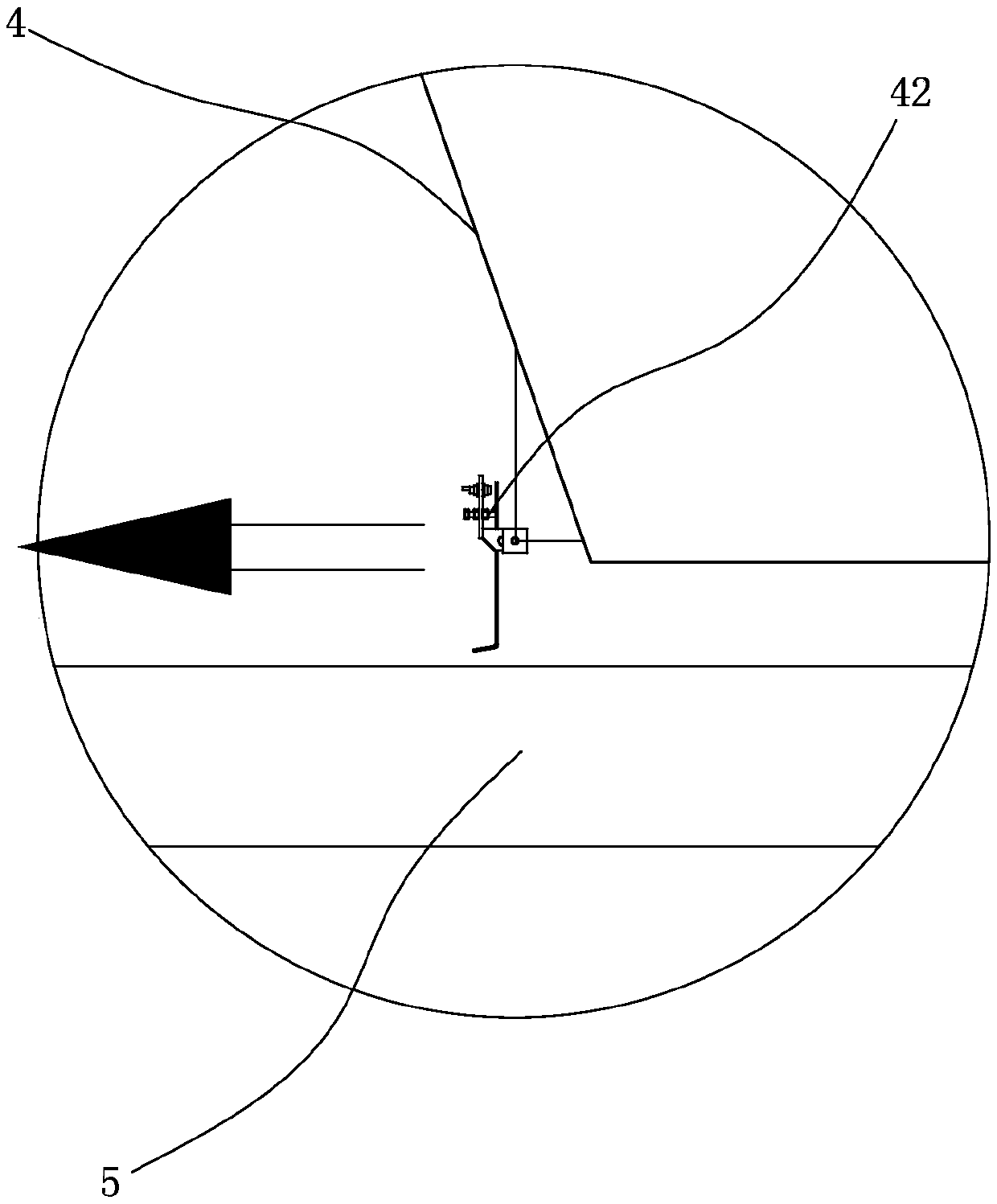

[0025] refer to Figure 1 to Figure 3 As shown, a recycled material feeding system of an asphalt mixing plant includes a recycled material supply device 1, a hoist 2, a switching device 3, a mixing bin 4, belt conveyors 5, 1, a second temperature sensor 91, a first Chute 312 and the second chute 32.

[0026] The asphalt mixing plant includes a drying drum 6, a burner 7, a combustion chamber 8 and an exhaust gas treatment device 9. The drying drum 6 is used to dry and heat the recycled materials; the burner 7 is used to supply heat to the drying drum 6; The chamber 8 is arranged between the output end of the drying drum 6 and the burner 7 ; the tail gas treatment device 9 is connected with the input end of the drying drum 6 for treating the tail gas coming out of the drying drum 6 .

[0027] The recycled material supply device 1 is used to supply recycled materials to the feed port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com