A CT triaxial test device for hydrate deposits

A technology for hydrate deposits and triaxial testing, which is applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as heat loss, CT image ghosting, and impossibility, and achieve improvement Stability, lower center of gravity, enhanced stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

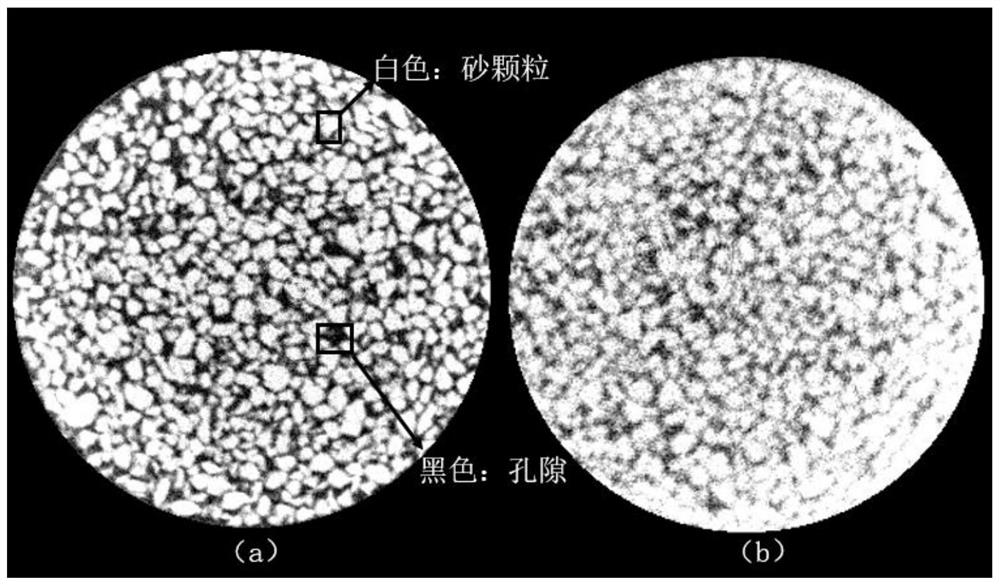

Image

Examples

Embodiment Construction

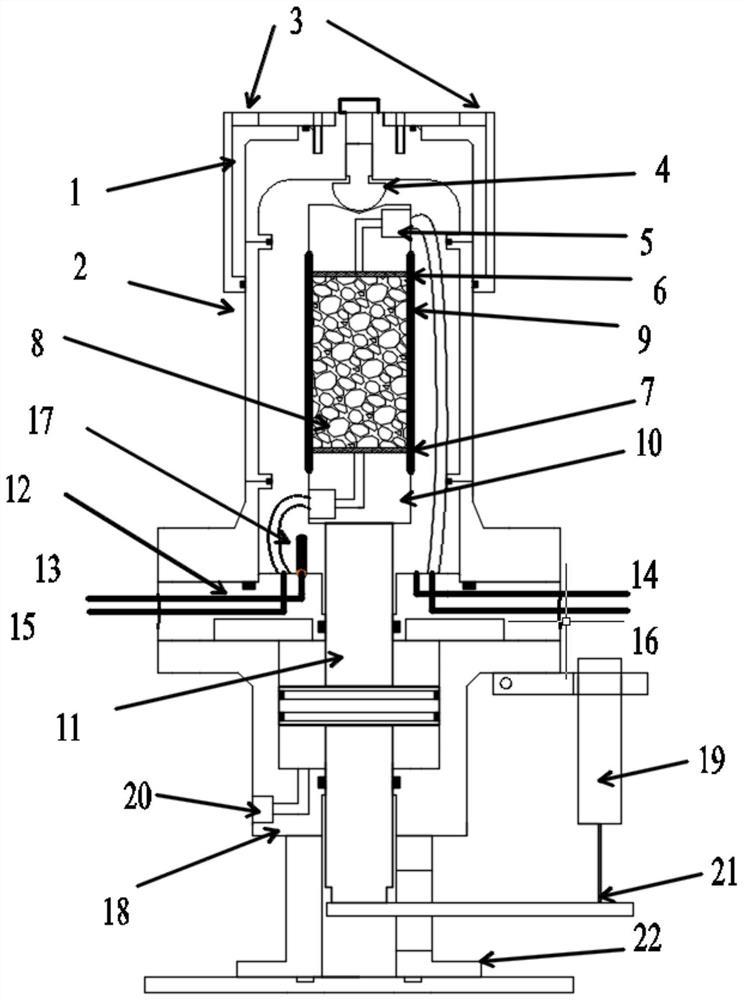

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

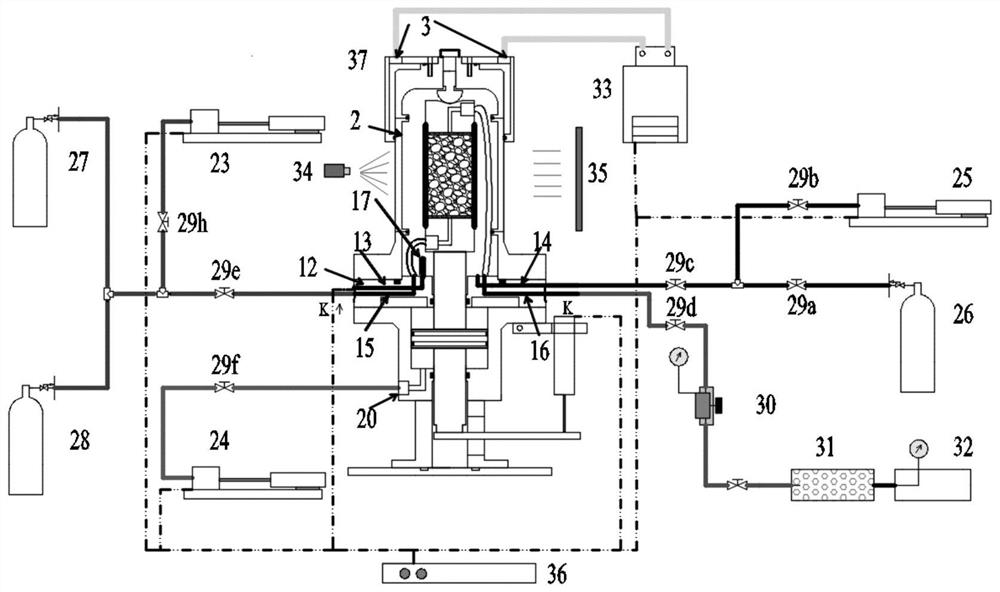

[0036] (1) Connecting pipeline: fix the bottom fixing bracket 22 of the hydrate deposit CT triaxial test device 37 to the micro-focus CT stage. according to image 3 , the coolant channel A3 of a hydrate deposit CT triaxial test device 37 is connected to the water bath 33 using a flexible pipeline to realize the temperature control of the pressure chamber 2; a hydrate deposit CT triaxial test device 37 The channel C14 of the channel C14 is connected with the high-precision pressure volume controller confining pressure 25 and the nitrogen gas source confining pressure 26 respectively through the needle valves 29a, 29b and 29c using flexible pressure-resistant pipelines to realize the confining pressure control of the sediment sample 8; The channel D15 of a hydrate sediment CT triaxial test device 37 is resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com