Display device and manufacturing method thereof

A display device and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., capable of solving problems such as limited adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The description of the following embodiments refers to the attached drawings to illustrate specific embodiments that the present invention can be implemented. Furthermore, the directional terms mentioned in the present invention, such as up, down, top, bottom, front, back, left, right, inside, outside, side, surrounding, center, horizontal, horizontal, vertical, vertical, axial, The radial direction, the uppermost layer or the lowermost layer, etc., are only the direction of reference to the attached drawings. Therefore, the directional terms used are used to describe and understand the present invention, rather than to limit the present invention.

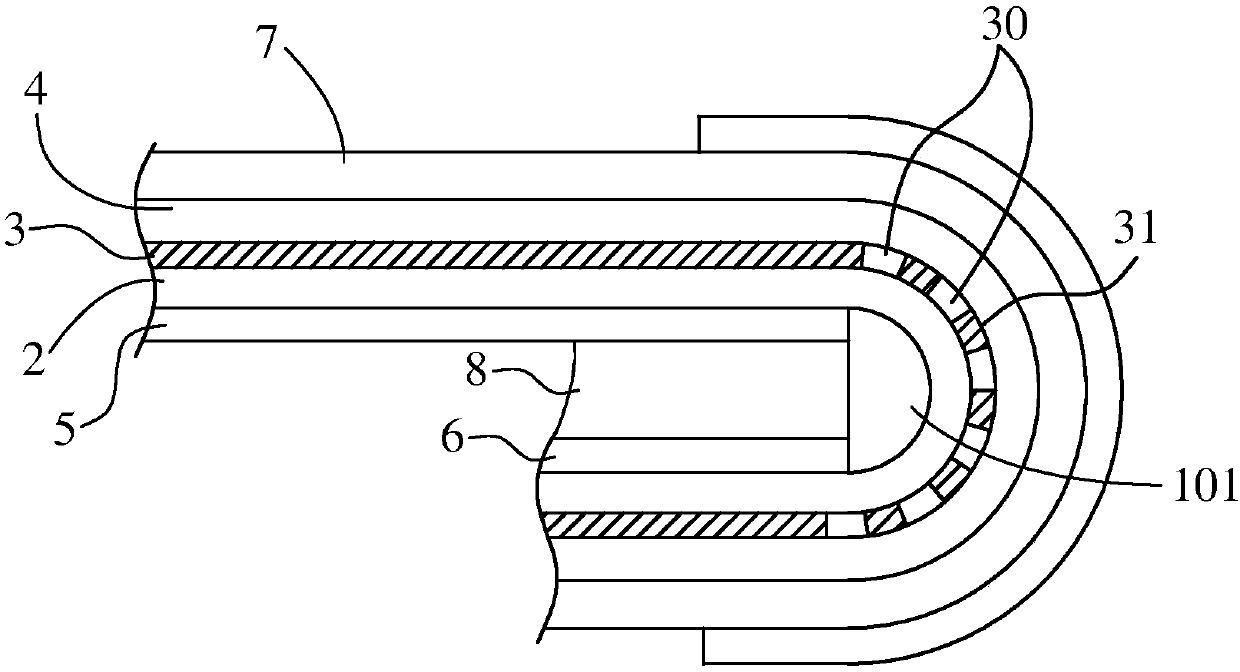

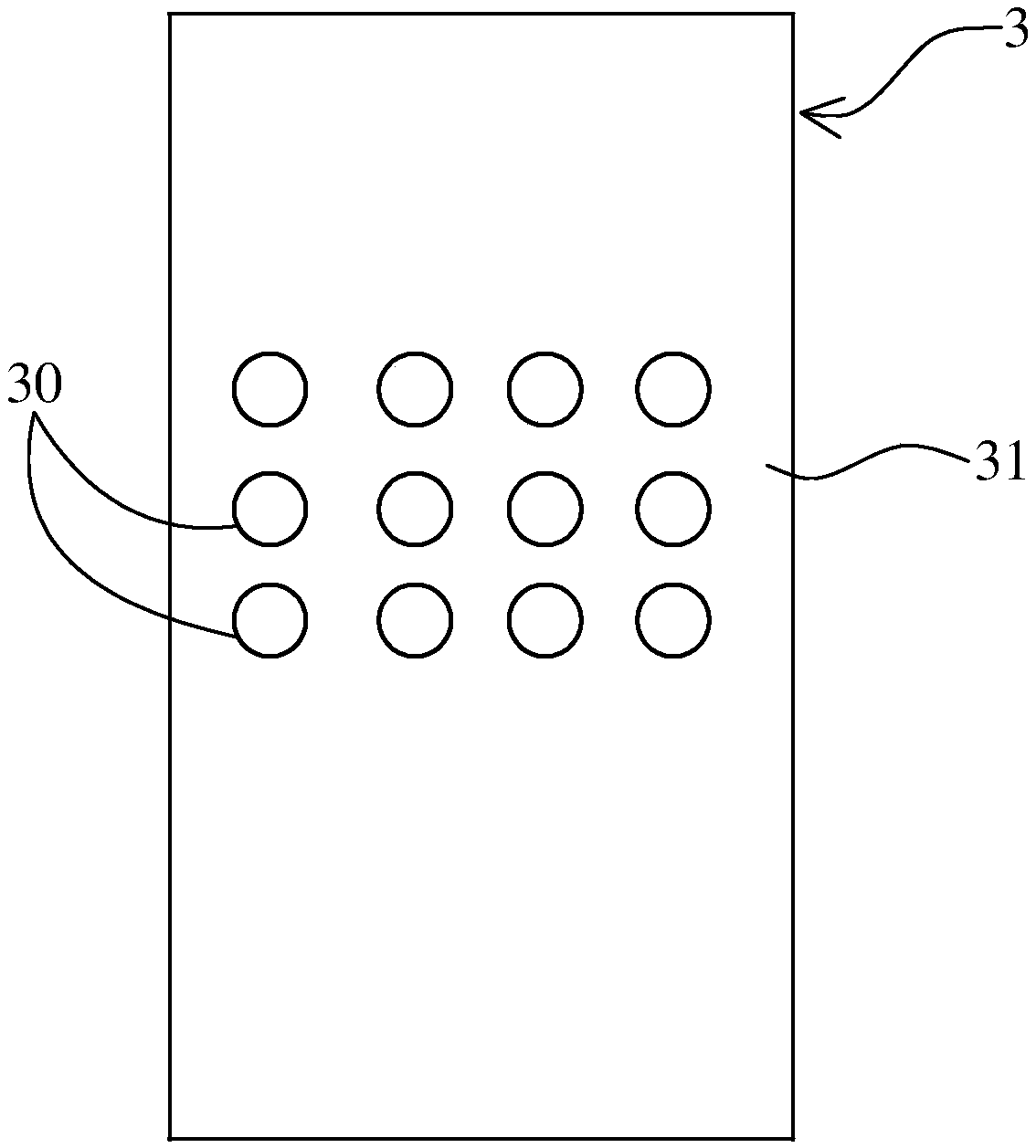

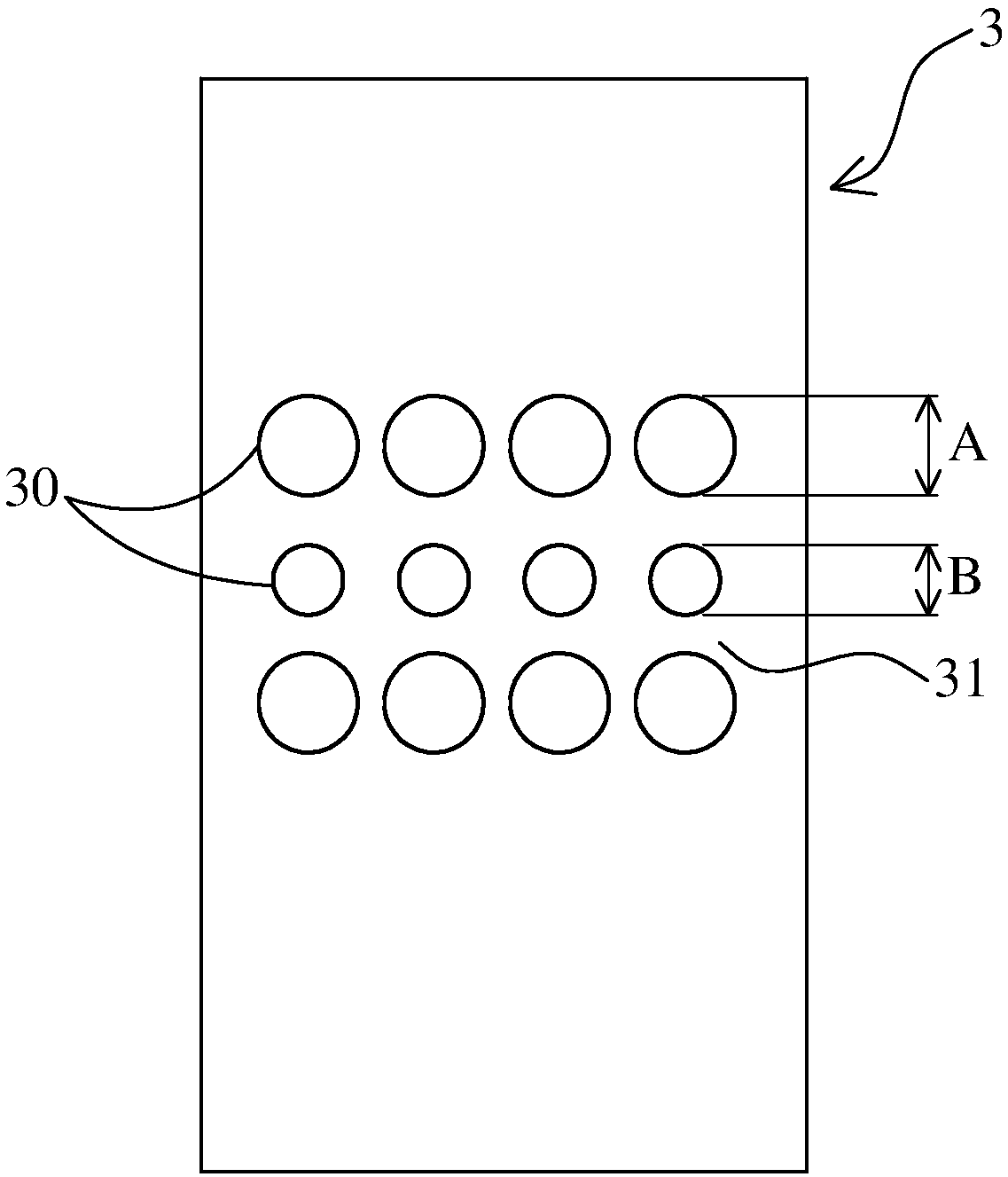

[0027] Please refer to figure 1 Shown is a schematic diagram of a preferred embodiment of the display device of the present invention. The display device includes a first flexible substrate layer 2, a buffer layer 3, a second flexible substrate layer 4, a first backplane 5 and a second backplane 6. The present invention will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com