A kind of walnut meal camellia and preparation method thereof

The technology of walnut meal and walnut meal powder is applied in the field of walnut meal camellia oil and its preparation, which can solve the problem of waste of high-quality protein resources, and achieve the effects of distinctive features, broad market prospects and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

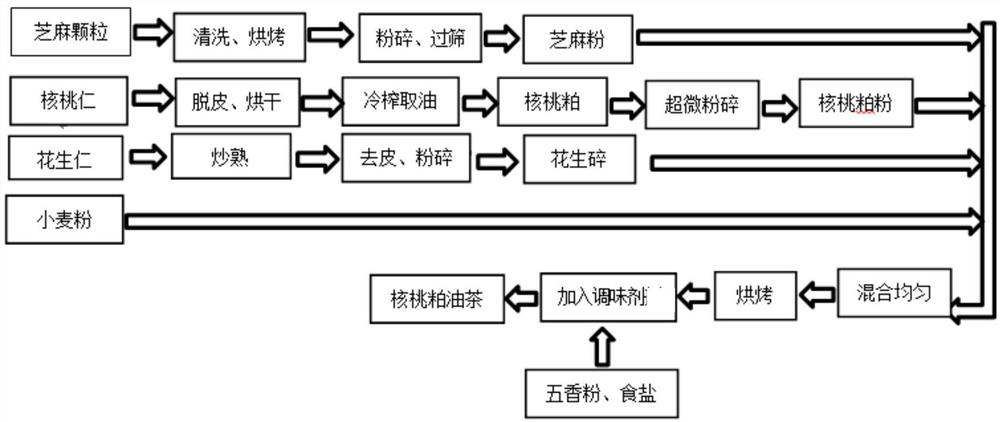

[0030] according to figure 1 The technological process of preparing walnut meal camellia oleifera, the concrete preparation method is as follows:

[0031] 1. Select high-quality walnut kernels, soak them in water for 36 hours, and change the water 3 times during the soaking process; then immerse the soaked walnut kernels in a food-grade sodium hydroxide aqueous solution with a mass fraction of 1.5%, and cook at 80-90 ° C for 1 min. Immediately remove and rinse the walnut kernels with high-pressure water until the seed coats of the walnut kernels completely fall off to obtain peeled walnut kernels; bake the peeled walnut kernels at 50-60°C until completely dry and then pulverize, and use the cold pressing method to extract the oil. The cold pressing pressure is 45MPa, the cold pressing temperature is 40℃, and the cold pressing is repeated three times to obtain low-fat, high-protein walnut meal, and the walnut meal is ultra-finely pulverized to obtain cold-pressed walnut meal po...

Embodiment 2

[0035] Steps 1 and 2 of this example are the same as those of Example 1. In step 3, 700g of cold-pressed walnut meal powder, 200g of wheat flour, 25g of ground peanuts, and 25g of sesame powder were mixed evenly, and the mixture was spread out on a baking pan to a thickness of About 5mm, then place the baking pan in a double-layer heating oven at 150°C for 10 minutes. 20 g of five-spice powder and 30 g of table salt were added to the roasted mixture, and the mixture was stirred evenly to obtain camellia oil with walnut meal.

Embodiment 3

[0037] Steps 1 and 2 of this example are the same as those of Example 1. In step 3, 700g of cold-pressed walnut meal powder, 100g of wheat flour, 45g of ground peanuts, and 35g of sesame powder are mixed evenly, and the mixture is spread on a baking pan to a thickness of About 5mm, then place the baking pan in a double-layer heating oven at 150°C for 10 minutes. 60 g of five-spice powder and 60 g of table salt are added to the roasted mixture, and the mixture is stirred evenly to obtain camellia oil with walnut meal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com