A large-flow reuse filter element and its matching cleaning process equipment and operation method

An operation method and high-flow technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low filtration accuracy, easy water scattering, secondary pollution, etc., and achieve increased filtration area, stable filtration accuracy, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

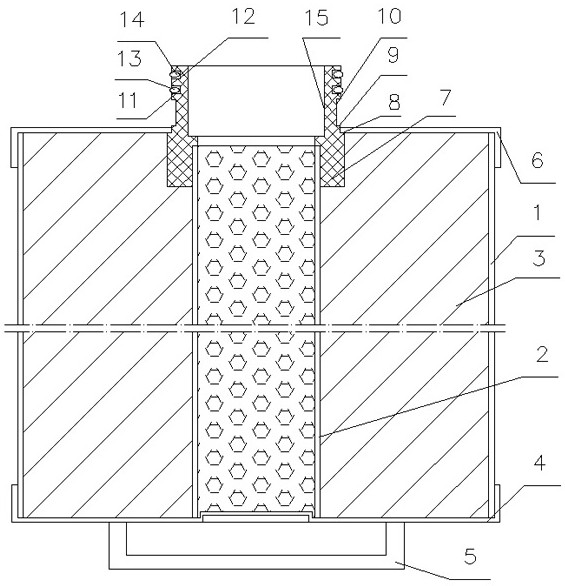

[0038] A large-flow reuse filter element and its supporting cleaning process equipment, its composition includes: an outer support cylinder 1, an inner support cylinder 2 is housed in the outer support cylinder, and the distance between the outer support cylinder and the inner support cylinder is Filter material 3 is installed in between, the bottom of the outer support cylinder is connected to the lower end cover 4, the lower end cover is connected to the support frame 5, the top of the inner support cylinder is connected to the sealing head, and the sealing head is connected to the upper end cover 6. The upper end cover is connected to the outer support cylinder, and the outer support cylinder, the inner support cylinder, the filter material, and the sealing head form a cleaning filter element.

Embodiment 2

[0040] A large-flow recycling filter element and its supporting cleaning process equipment described in Example 1, the sealing head includes a sealing sleeve 7, and the sealing sleeve is fitted on the outer circle of the inner support cylinder. The sealing sleeve has a first-level boss 8, the first-level boss supports and connects the upper end cover, the sealing sleeve has a second-level boss 9 and a ring groove 10, and the top of the sealing sleeve has a The primary seal groove 11 and the secondary seal groove 12, the primary seal groove is connected to the lower seal ring 13, the secondary seal groove is connected to the upper seal ring 14, the top of the seal sleeve has a cavity 15, the The cavity described above is connected to the inner support cylinder.

Embodiment 3

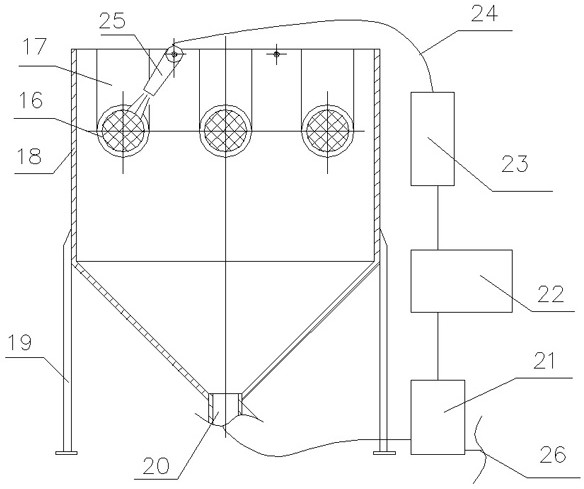

[0042] A large-flow reuse filter element and its supporting cleaning process equipment described in Example 1, the cleaning filter element is installed in the suspension ring 16, the suspension ring is connected to the suspension plate 17, and the suspension plate is connected to the water collection tank 18 , the connecting bracket 19 of the water collection tank, the bottom of the water collection tank has a cleaning sewage discharge port 20, the cleaning sewage discharge port is connected to the sewage purification filter 21, and the sewage purification filter is connected to the clean water tank 22. The clean water tank is connected to a high-pressure water washer 23, the high-pressure water washer is connected to a high-pressure water hose 24, the high-pressure water hose is connected to a high-pressure water nozzle 25, and the high-pressure water nozzle is aligned with the Rinse the filter element as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com