Stable type grinding wheel grinding unit structure

A stable and grinding wheel technology, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., can solve the problems of personal injury and safety hazards, and achieve the effects of improving safety, prolonging service life, and using safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

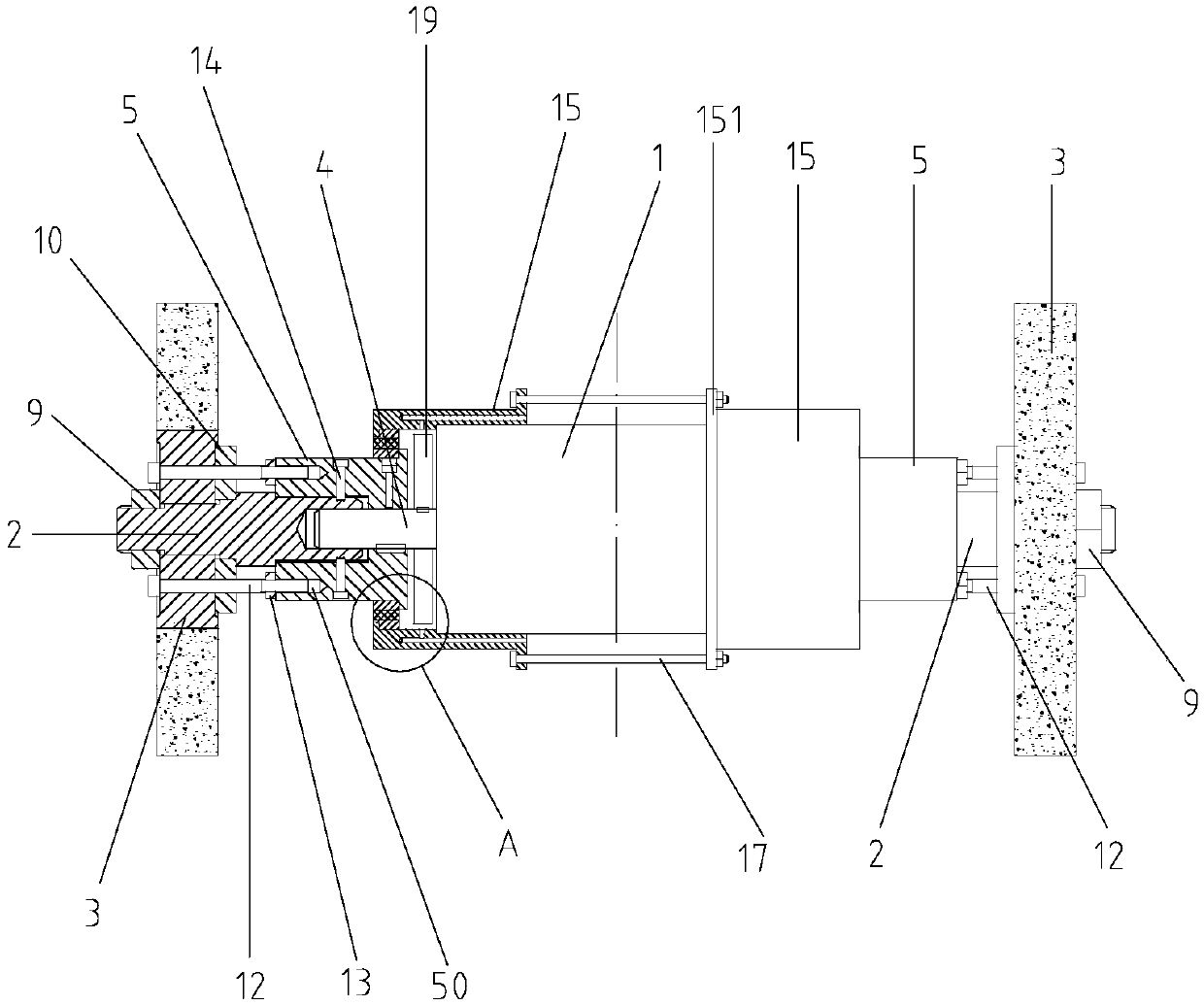

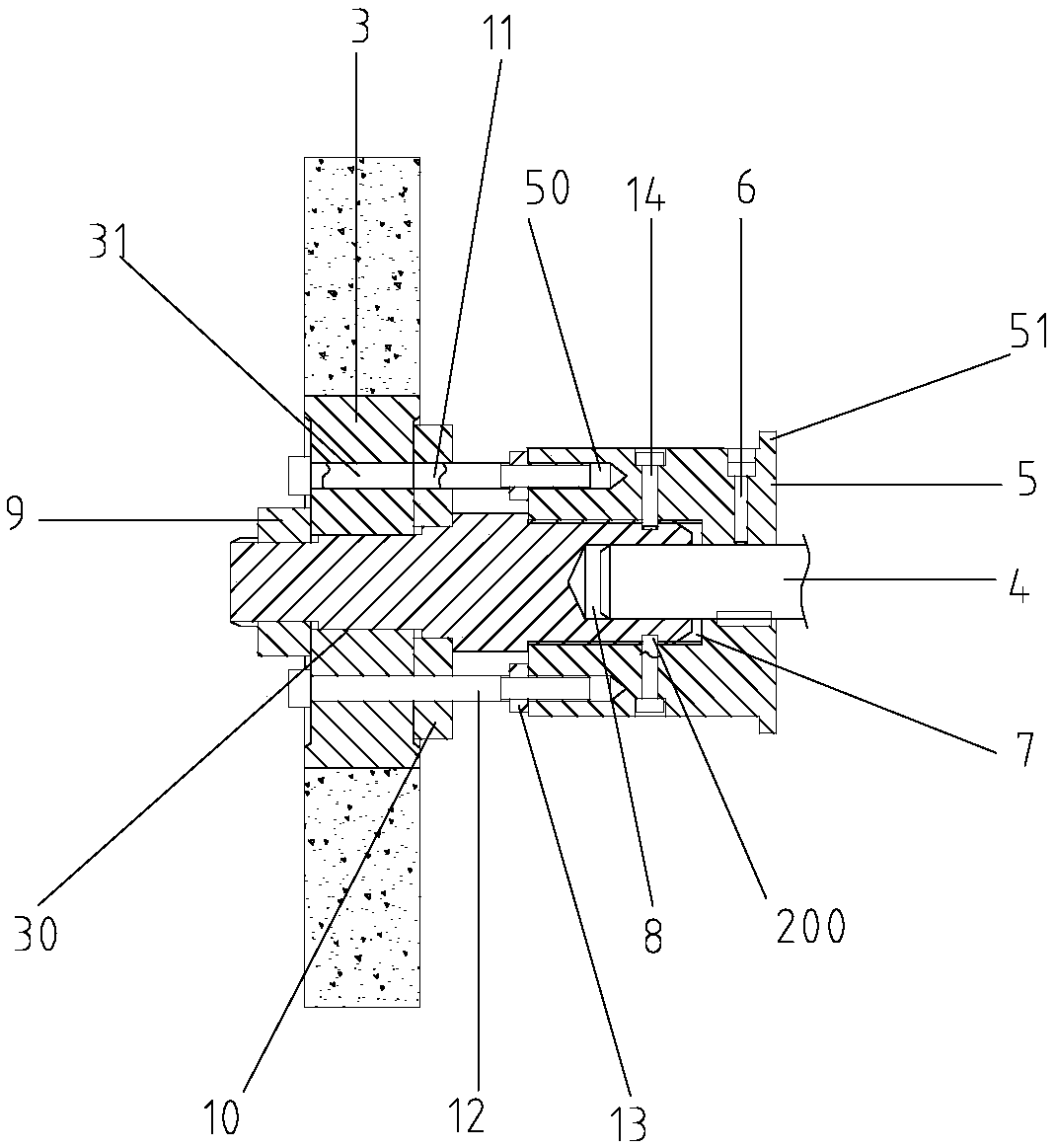

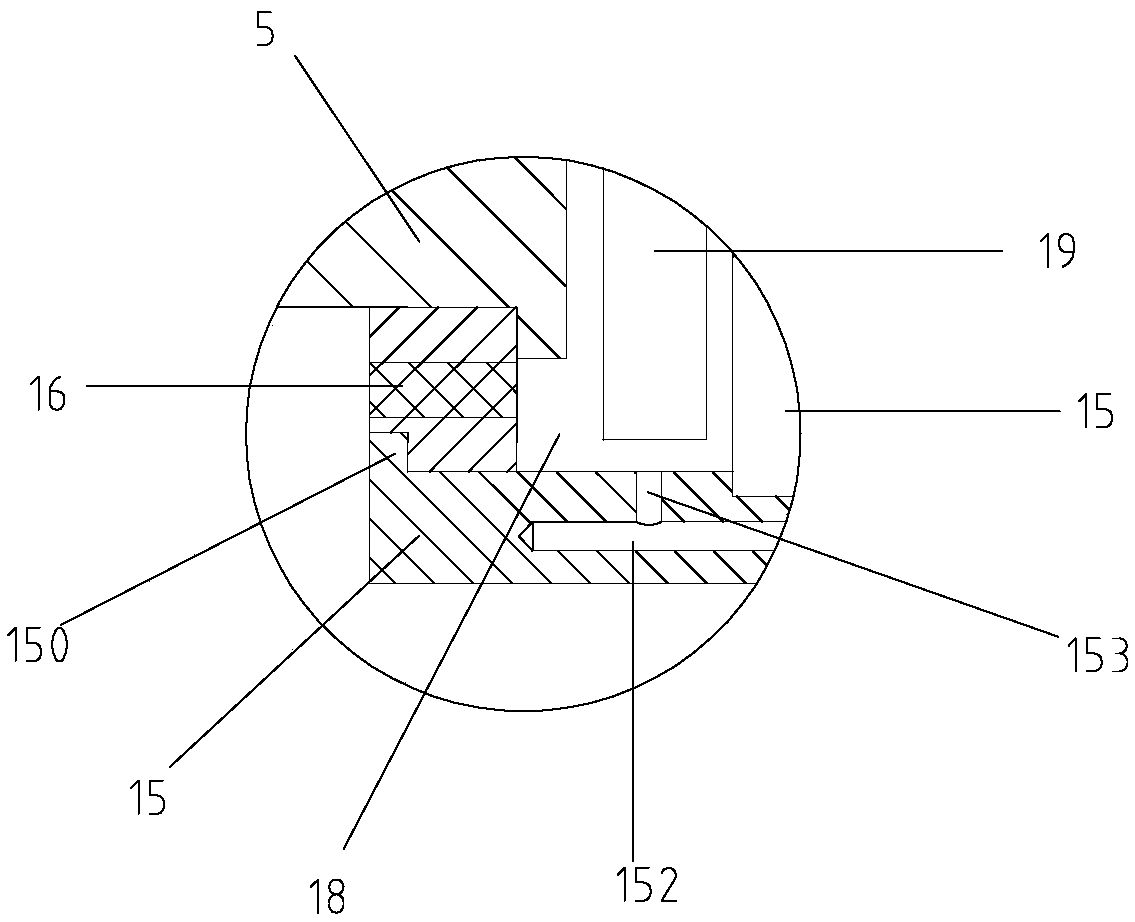

[0018] Such as figure 1 and figure 2 The shown assembly structure of a stable grinding wheel grinder includes a double-head motor 1, two grinding wheel shafts 2, and two grinding wheels 3. The motor shaft 4 of the double-head motor is equipped with a connecting seat 5, and the side of the connecting seat There is a locking bolt 6, the connecting seat is fixed with the motor shaft through the locking bolt, the front end of the connecting seat is provided with a threaded hole 7, and the inner end of the grinding wheel shaft is provided with a central hole 8, and the two motor shafts extend into the two motor shafts one by one. The center hole of the grinding wheel forms a clearance fit with the center hole, and the outer side of the inner end of the grinding wheel shaft is threadedly connected with the threaded hole. The center of the grinding wheel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap