Glass fiber pipe production device

A production device and glass fiber technology, applied in the field of glass fiber pipe production devices, can solve the problems of increasing the probability of pipe breakage, safety accidents, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

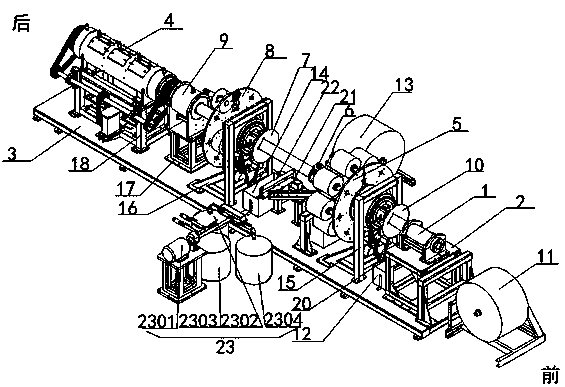

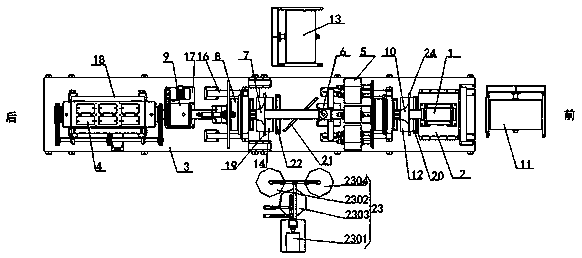

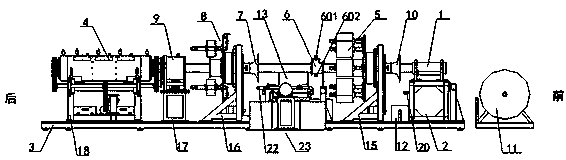

[0056] This embodiment provides a glass fiber pipe production device, such as Figures 1 to 3 , as shown, the mandrel 1 is horizontally fixed on the frame 3 through the first bracket 2, and the wrapping cloth frame 11 and the tractor (not shown in the figure) are both fixed on the frame 3 and are respectively located at the front end and the At the end, along the axial direction of the core mold 1, there are sequentially arranged a first wrapping plate 10, a winding yarn assembly 5, a fixed sizing box 6, a second wrapping plate 7, a wrapping cloth assembly 8, a rotating sizing assembly 9 and a forming furnace assembly 4. The first glue box 12 is fixed on the frame 3 and is located between the wrapping cloth frame 11 and the winding yarn assembly 5. A first radial guide shaft 24 is installed in the first glue box 12. Between the wrapping cloth frame 11 and the second Between the plastic boxes 12, there is also a material passing wheel 20 fixed on the first support 2; the fiber ...

Embodiment approach 2

[0067] This embodiment is a further improvement of Embodiment 1. The main improvement is that, in Embodiment 1, the angle at which the wrapping cloth in the wrapping cloth frame 808 is wound onto the mandrel 1 cannot be adjusted, while the wrapping cloth is wound onto the mandrel. The angle on 1 directly affects the strength and toughness of the final glass fiber pipe, so the production device of the glass fiber pipe in embodiment 1 cannot be adjusted according to the needs of product performance, and the scope of application is narrow. In this embodiment, the angle at which the wrapping cloth is wound onto the mandrel 1 can be adjusted, so that the glass fiber pipe production device in this embodiment can be adjusted accordingly according to the product performance, and the scope of application is wider.

[0068] Specifically, in this embodiment, the wrapping cloth assembly 8 also includes an angle adjustment mechanism connected to the front end of the third bearing seat 810 t...

Embodiment approach 3

[0071] This embodiment is a further improvement of Embodiment 2. The main improvement is that in Embodiment 2, during the gluing process of the rotary gluing assembly 9, uneven gluing often occurs and excess glue cannot be discharged from the rotating drum. In some cases, the surface of the final fiberglass pipe is not smooth, and the quality of the glass fiber cannot meet the requirements. However, in this embodiment, the above defects can be effectively avoided, the gluing in the rotary gluing assembly 9 can be made uniform, and excess glue can be effectively discharged from the rotary drum 903 .

[0072] Specifically, in this embodiment, as Figure 18 A screw groove 909 with a preset length is provided on the inner wall of the end of the rotary cylinder 903 in the rotary glue application assembly 9. The beginning of the screw groove 909 is located at the rear side of the glue injection hole 907, and the thread of the screw groove 910 is from the beginning to the end. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com