Four-direction shuttle carrier for stereoscopic warehouse

A technology of three-dimensional warehouse and shuttle car, which is applied in the direction of transportation, packaging and storage devices, etc. It can solve the problems of low transmission efficiency and complex hydraulic transmission structure, so as to improve efficiency, save the time for changing directions when leaving the warehouse, and have strong grip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

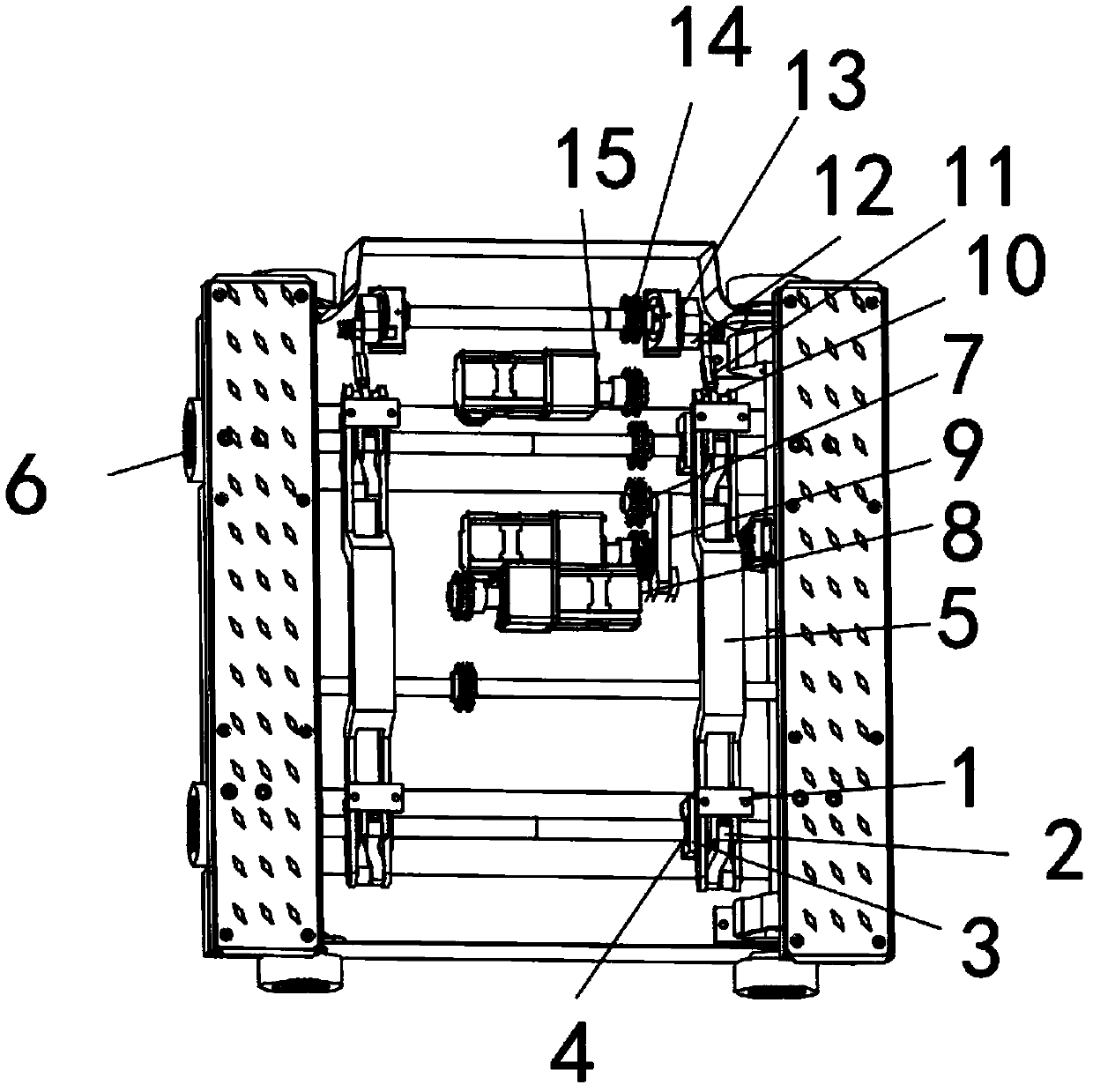

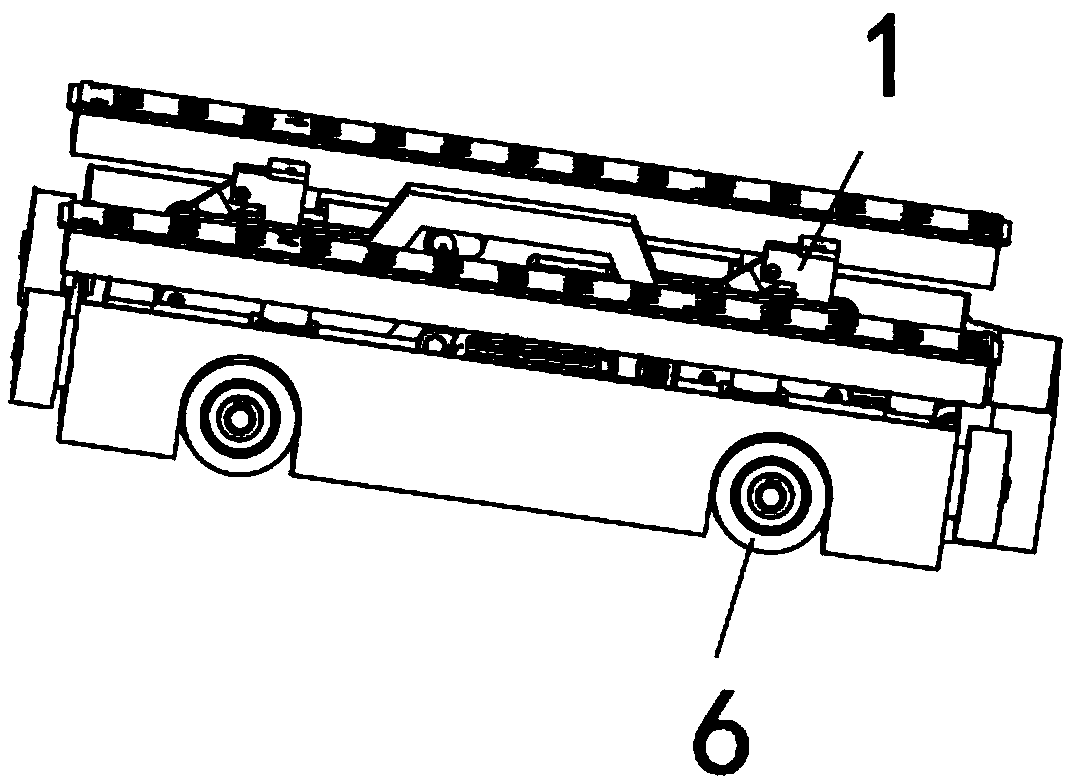

[0016] Such as Figure 1-2 As shown, a four-way shuttle vehicle for a three-dimensional warehouse includes a wheel jacking mechanism fixing bracket 1, a servo gear motor 8 and a power group servo gear motor 15, and a long connecting rod 5 is provided on one side of the wheel jacking mechanism fixing bracket 1, There are two sets of wheel jacking mechanism fixed bracket 1 and long connecting rod 5. The two long connecting rods 5 are parallel to each other. The other side of the wheel jacking mechanism fixed bracket 1 is provided with a small connecting rod 2. The end of each long connecting rod 5 Both are connected with the small connecting rod 2, the bottom of the fixed bracket 1 of the wheel jacking mechanism is provided with the bearing seat 3 of the driving shaft of the jacking mechanism, the bearing cover 4 is provided under the bearing seat 3 of the driving shaft of the jacking mechanism, and the other side of the long connecting rod 5 is connected Hexagonal rod 11, joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com