A resource allocation optimization method for a four-way shuttle-type intensive storage system

A warehousing system and resource allocation technology, applied in storage devices, transportation and packaging, etc., can solve the problems of increased investment cost, large remodeling cost, material waste, etc., so as to improve the economic benefit of the enterprise, improve the operation efficiency, and reduce the investment. The effect of cost and logistics expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Attached below Figure 1-9 and specific implementation methods, the present invention will be further explained.

[0048] A resource allocation optimization method for a four-way shuttle-type intensive storage system of the present invention comprises the following steps:

[0049] Step 1. Transform the resource allocation system of the shuttle-type intensive storage system into a model under the OXYZ coordinate system;

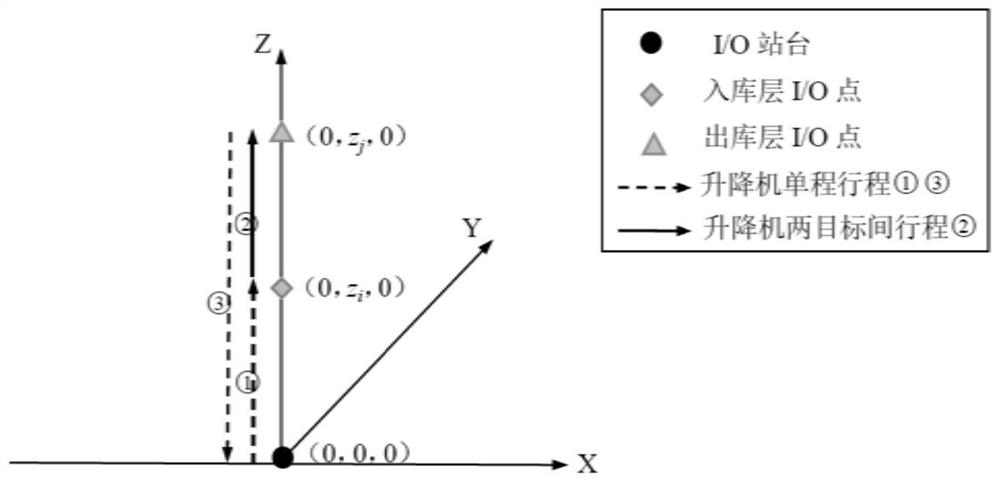

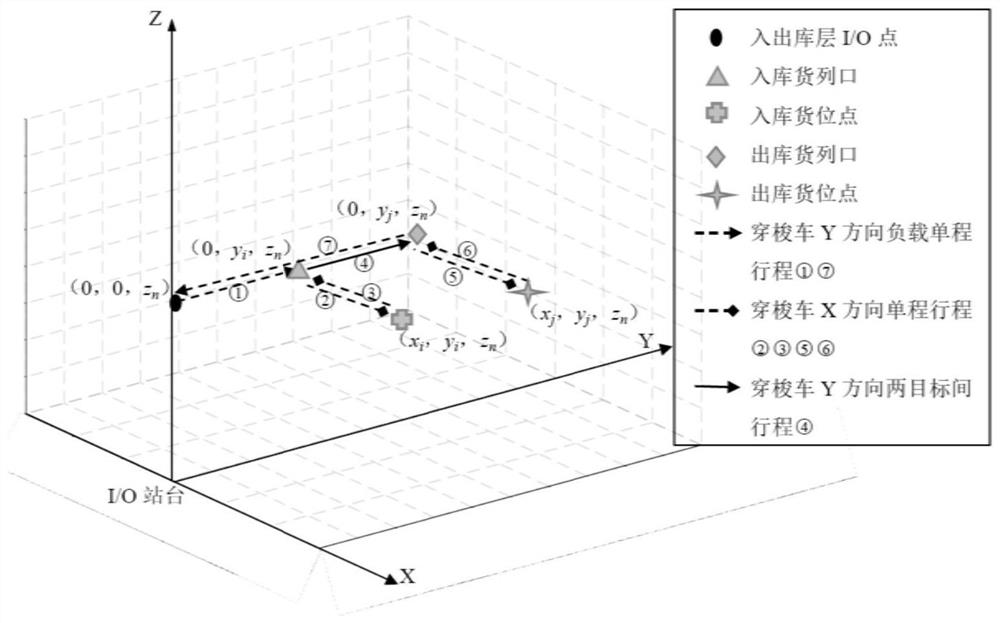

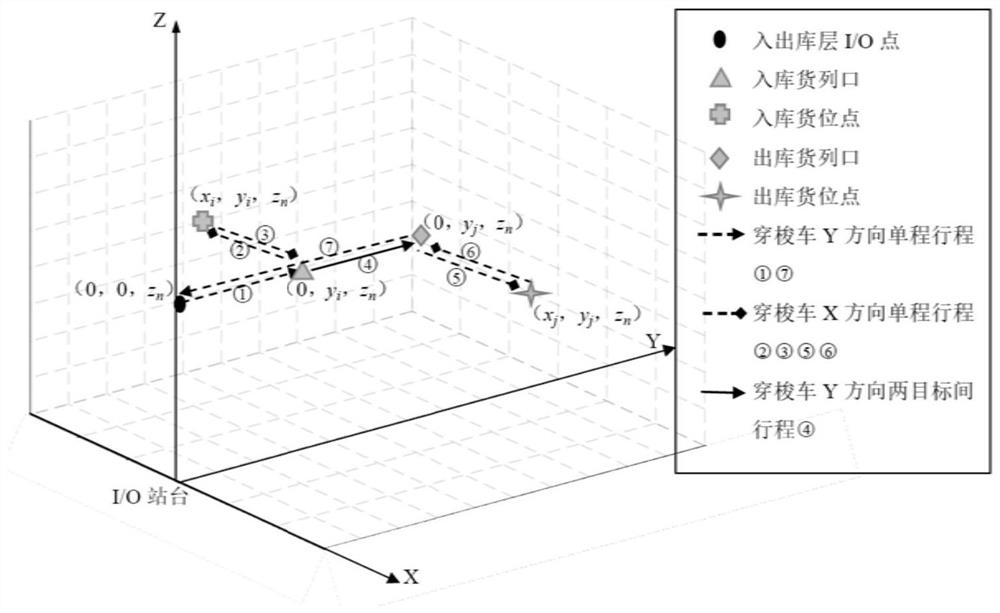

[0050] Take the I / O platform of the storage system as the coordinate origin O; take the running direction of the shuttle car’s cargo storage lane as the X-axis, when the shuttle car runs on the X-axis, it can reach different rack rows; take the running direction of the main channel of the shuttle car as the Y-axis, the shuttle car When the Y-axis is running, it can reach different shelf rows; if the vertical running direction of the elevator is the Z-axis, when the elevator is running vertically on the Z-axis, it can reach different shelf layers;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com