Method for treating cow dung fermented biogas slurry with combined ozone and flocculation

A flocculation and cow dung technology, which is applied in the field of pretreatment of cow dung fermentation biogas slurry, can solve the problems of poor biodegradability and high solid colloid content, and achieve the effects of short reaction time, reduced oxidation cost and enhanced effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

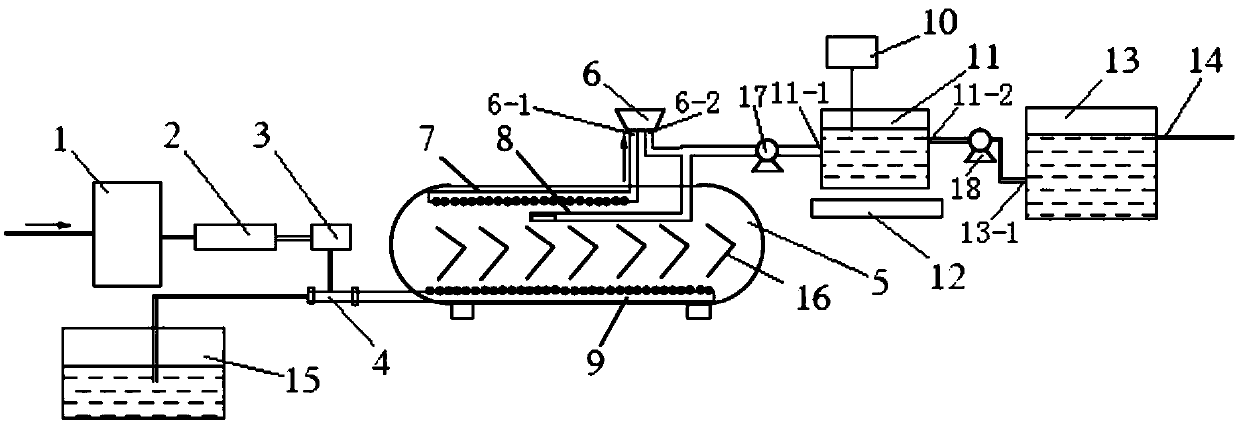

[0010] Specific implementation mode one: this implementation mode is a kind of method of ozone flocculation combination treatment cow dung fermentation biogas liquor, specifically is finished according to the following steps:

[0011] Ozone oxidation treatment is first performed on the fermented cow dung biogas slurry to obtain the oxidized cow dung fermented biogas slurry, and then flocculation and sedimentation treatment is performed on the oxidized cow dung fermented biogas slurry to obtain the treated cow dung fermented biogas slurry.

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific process of the ozone oxidation treatment is as follows: the form of aeration is used to inject ozone into the cow dung fermentation biogas slurry, and the rate of ozone injection is 2g / h ~2.4g / h·L, aeration time 35min~45min, the mass ratio of the total amount of ozone added to the COD in the cow dung fermentation biogas slurry is (0.3~0.4):1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pH in the ozone oxidation treatment process is 7.5-8. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com