A two-component low-viscosity base crack rapid repair material

A repair material, low viscosity technology, used in roads, pavement details, buildings, etc., can solve the problem that the base layer and the crack repair material cannot be well bonded together, the service life of the crack repair material is shortened, and the base layer cannot be bonded. It can achieve the effect of good steric hindrance effect, fast setting time, simple and easy-to-use construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

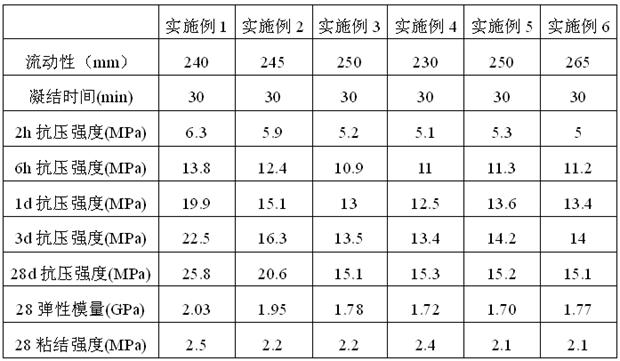

Examples

Embodiment 1

[0022] Embodiment 1 A kind of two-component low-viscosity type base crack fast repairing material, this repairing material is made up of A component and B component; Wherein

[0023] Component A is calculated in parts by weight (kg), consisting of 70 parts of rapid hardening sulfoaluminate cement, 12 parts of fly ash, 3 parts of silica fume, 50 parts of quartz powder, 0.3 parts of water reducer, 3 parts of expansion agent, It is formed by mixing 0.1 part of foaming agent and 0.45 part of boric acid;

[0024] Component B is calculated in parts by weight (kg), and is prepared by mixing 12 parts of carboxylated styrene-butadiene latex and 38.25 parts of water.

Embodiment 2

[0025] Embodiment 2 A kind of two-component low-viscosity type base crack fast repairing material, this repairing material is made up of A component and B component; Wherein

[0026] Component A is calculated in parts by weight (kg), consisting of 70 parts of rapid hardening sulfoaluminate cement, 11 parts of fly ash, 4 parts of silica fume, 50 parts of quartz powder, 0.27 parts of water reducer, 3 parts of expansion agent, 0.1 part of foaming agent, 0.44 part of boric acid and 0.1 part of cellulose are mixed;

[0027] Component B is calculated in parts by weight (kg), and is prepared by mixing 12 parts of carboxylated styrene-butadiene latex and 42.5 parts of water.

Embodiment 3

[0028] Embodiment 3 A kind of two-component low-viscosity base crack fast repairing material, this repairing material is made up of A component and B component; Wherein

[0029] Component A is calculated in parts by weight (kg), consisting of 70 parts of rapid hardening sulfoaluminate cement, 10 parts of fly ash, 5 parts of silica fume, 50 parts of quartz powder, 0.25 parts of water reducer, 3 parts of expansion agent, 0.1 part of foaming agent, 0.42 part of boric acid and 0.2 part of cellulose are mixed;

[0030] Component B is calculated in parts by weight (kg), and is prepared by mixing 12 parts of carboxylated styrene-butadiene latex and 46.75 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com