Three-dimensional coordinate measuring construction method for short line method segment

A technology of three-dimensional coordinates and construction methods, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low adjustment efficiency, low adjustment accuracy, hidden safety hazards of bridges, etc., achieve significant social benefits, reduce measurement errors, The effect of timely and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

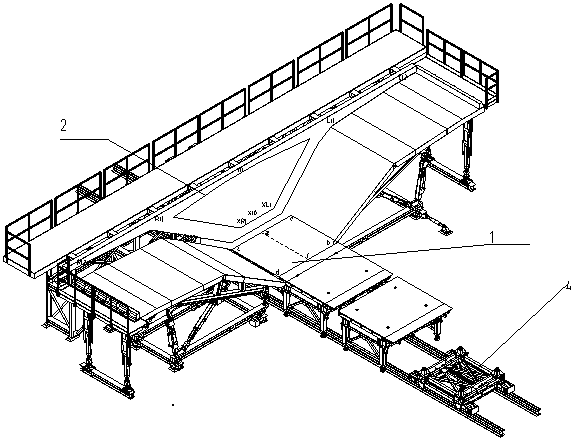

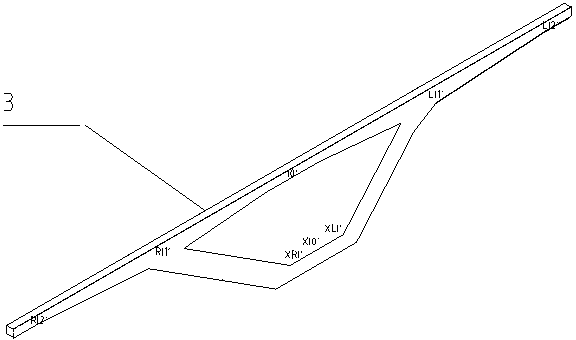

[0028] In the implementation of the present invention, a three-dimensional coordinate measurement construction method of a short-line method segmental beam is provided, such as figure 1 As shown, it includes bottom mold 1, fixed end mold 2, movable end mold 3, mobile trolley 4 in the prefabrication plant, calibrated total station, prism, steel ruler, hydraulic jack installed on the bottom mold for adjusting the bottom mold The height, three-dimensional coordinate measurement construction method includes the following steps:

[0029] Step (1): Set up the measuring pier. Based on the layout design drawing of the prefabricated pedestal of the segmental beam, respectively arrange the measuring pier and the target pier on the central axis of the pedestal, and connect the measuring pier and the target pier to form a reference center line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com