Circular bar buckling and anchoring assembly type shear wall composite structure system and installation method

An installation method and shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult construction, poor waterproof performance, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

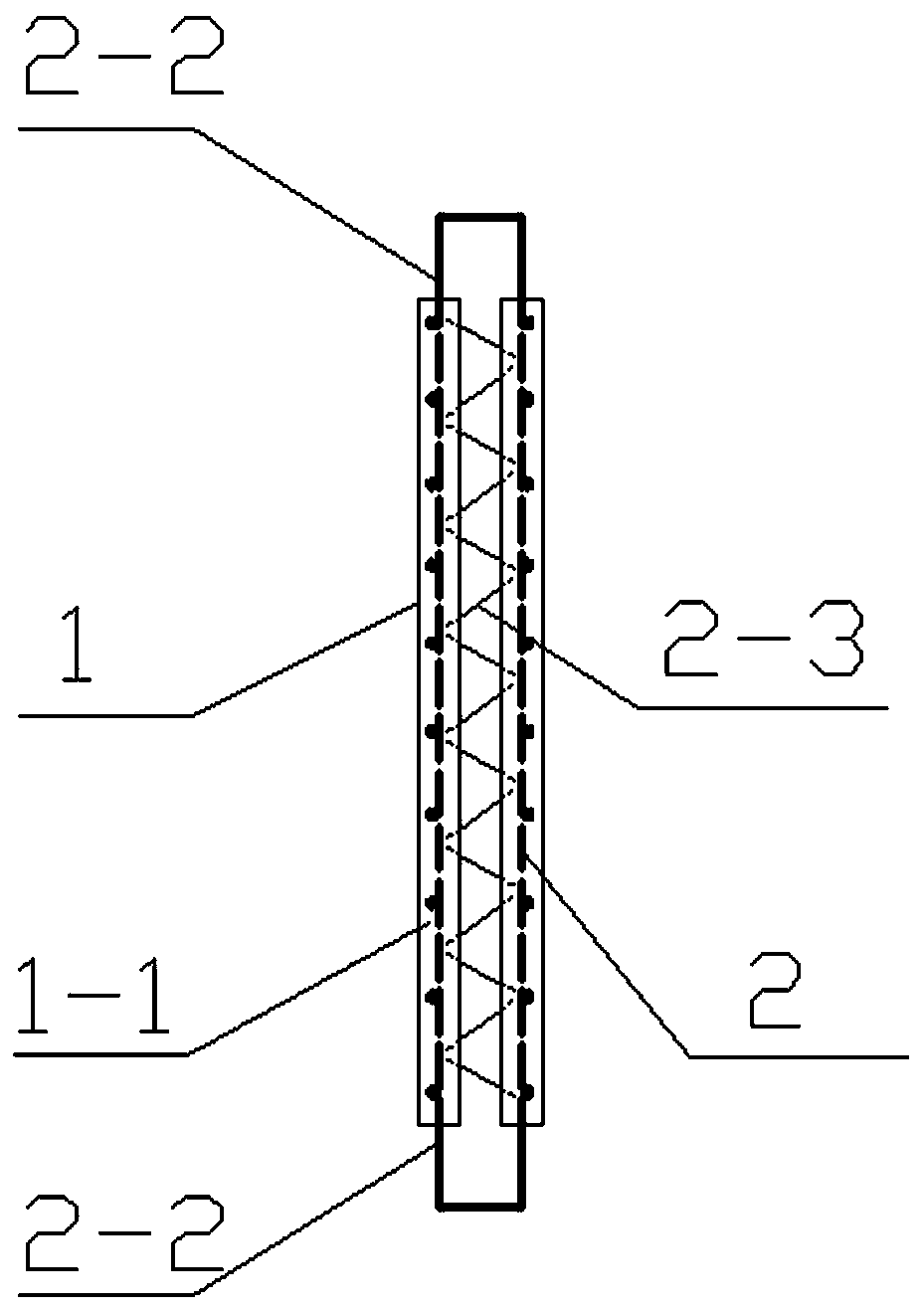

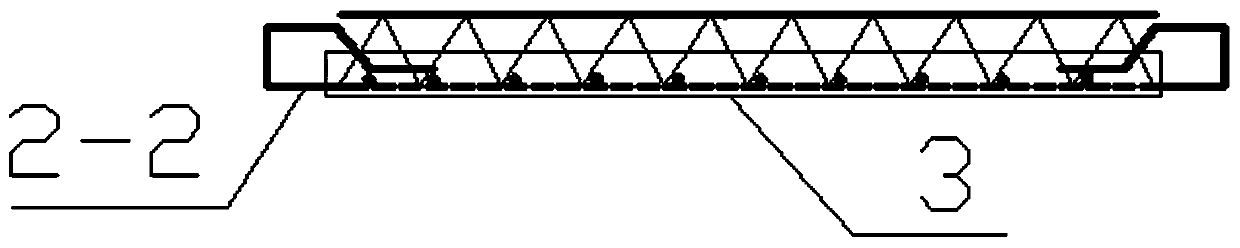

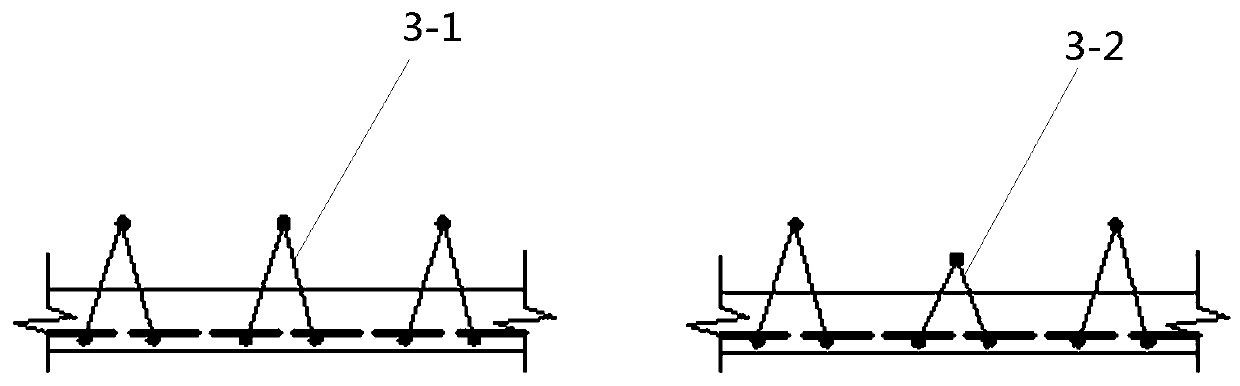

[0079] Embodiment 1, a ring-reinforced fastening and anchoring assembled shear wall composite structure system, including vertical component connections and horizontal component connections, such as figure 1 with figure 2 As shown, both the vertical and horizontal components include a hollow prefabricated laminated concrete shear wall 1 and a prefabricated floor 3, and the hollow prefabricated laminated concrete shear wall 1 includes two symmetrically arranged thin shear walls 1-1, There is a truss reinforcement 2-3 connection between the two thin shear walls 1-1, and the internal reinforcement of the two thin shear walls 1-1 is a closed circular reinforcement, and the exposed concrete surface around the closed circular reinforcement is a circular anchor reinforcement 2-2 . Such as figure 1 As shown, the vertical butt joint surfaces on both sides of the hollow prefabricated composite concrete shear wall 1 are provided with several annular anchoring reinforcement bars 2-2, s...

Embodiment 2

[0083] Embodiment 2, an installation method of a ring-bar fastening and anchoring assembled shear wall composite structure system, including vertical component installation and connection and horizontal component installation and connection, the vertical component installation and connection process is as follows Figure 4-8 shown, including the following steps:

[0084] Step 1: If Figure 4 As shown, install the hollow prefabricated laminated concrete shear wall 1 on the lower floor, and pour concrete in the middle of the two thin shear walls 1-1 until the concrete is 10-20cm away from the top of the thin shear wall or poured to the thin shear wall 1-1 top.

[0085] Step 2: Horizontally hoist the prefabricated floor slabs 3 on both sides of the hollow prefabricated laminated concrete shear wall 1 described in step 1, so that the anchor bars 2 on the upper part of the hollow prefabricated laminated concrete shear wall 1 in the lower layer described in step 1 are hoisted horiz...

Embodiment 3

[0099] Embodiment 3, an installation method of a ring-reinforcement anchorage assembled shear wall composite structure system, the T-shaped connection includes the method of T-shaped external ring-reinforcement buckle and the method of T-shaped direct buckle, and the T-shaped connection The legality of the outer ring rib buckle is as follows Figure 12 shown, including the following steps:

[0100] Step 13: hoist the three pages of hollow prefabricated laminated concrete shear walls 1 into place, so that the three pages of hollow prefabricated laminated concrete shear walls 1 form a T-shaped arrangement.

[0101] Step 14: Place ring-shaped steel bars 4 at the butt joints of the three-page hollow prefabricated composite concrete shear walls 1 described in step 13. There are two ring-shaped steel bars 4, and the two ring-shaped steel bars 4 form a T-shaped composite bar. The three ends of the T-shaped composite reinforcement are respectively lapped on the annular anchoring rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com