Outburst coal seam hole protecting device and screen pipe insertion method thereof

A technology for protruding coal seams and protecting holes, which is applied in the direction of earthwork drilling, mining fluids, wellbore/well components, etc. It can solve the problems of screen pipes being easily stuck and jack-up drill bits not easy to jack-up, etc., so as to improve the transmission efficiency , improve drilling efficiency, solve the effect that is difficult to fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

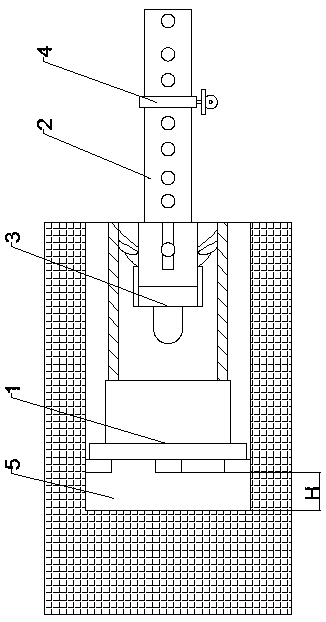

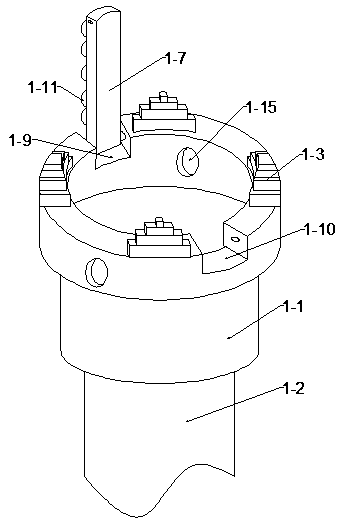

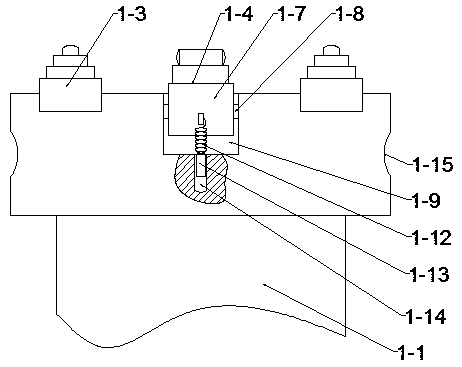

[0030] Example 1, such as Figure 1-5 As shown, a hole protection device for outburst coal seams includes a drilling tool 1, a screen pipe 2, a suspension assembly 3 and a sliding support assembly 4. One end of the screen pipe 2 is threaded with a suspension assembly 3, and the suspension assembly 3 is connected to the drilling tool 1. In cooperation, the suspension assembly passes through the drilling tool and is fixed on the wall of the borehole (that is, the coal wall) for fixing the screen pipe. The sliding support assembly 4 is connected with the screen pipe 2 for supporting the screen pipe. The drilling tool 1 comprises a drill body 1-1 and an auger body 1-2, the auger body and the auger body are hollow bodies, and the front end of the auger body 1-2 is threadedly connected to the rear end of the auger body 1-1, The drill bit body 1-1 is provided with a gradual cutting tooth 1-3 and a movable tooth plate assembly 1-4, one end of the movable tooth plate assembly 1-4 is h...

Embodiment 2

[0033] Example 2, such as Figure 6-7 As shown, a protruding coal seam hole protection device, the suspension assembly 3 includes a suspension cylinder 3-1, the suspension cylinder 3-1 is hollow in the middle, which is convenient for the retraction of the main claw and the aileron claw, and the suspension cylinder 3 The rear end of -1 is provided with a threaded connection for easy connection with the screen. The cylinder wall of the suspension cylinder 3-1 is provided with an opening and closing opening 3-4 and a chute 3-5, and the main wing claw cooperates with the opening and closing opening to facilitate it to be smoothly folded in the suspension cylinder. A sliding shaft 3-6 is arranged in the chute 3-5, and the sliding shaft can slide in the chute. The connecting rod 3-7 is hinged on the sliding shaft 3-6, and the main wing claw 3-1 is hinged in the suspension cylinder 3-1. 2. The main claw 3-2 is hinged with the connecting rod 3-7, and the main claw 3-2 is hinged with ...

Embodiment 3

[0037] Embodiment 3, a screen pipe lowering method for a device for protecting a hole in a protruding coal seam, comprising the following steps: S1: after the drilling construction is completed, the auger rod 1-2 and the drill bit body 1-1 stay in the borehole 5;

[0038] S2: The auger drill rod 1-2 and the drill bit body 1-1 withdraw a certain distance to the outside of the drill hole, and reserve a fixed space for the suspension assembly 3. At this time, the distance H between the drill bit body 1-1 and the bottom of the drill hole 5 =0.5~1.5m.

[0039] S3: Connect the suspension assembly 3 with the screen pipe 2, and transport it to the inside of the borehole 5 through the auger drill rod 1-2 and the drill bit body 1-1; body.

[0040] S4: After the first screen pipe is transported into the borehole, connect the next screen pipe in turn. During the process of connecting the screen pipes, clamp a sliding support assembly 4 on the screen pipe every 10m, and adjust the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com