A Double Internal Engagement Reversing Mechanism

An internal meshing, up-and-down technology, applied in the field of vehicle transmission, can solve the problems of complex structure and large number of parts, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

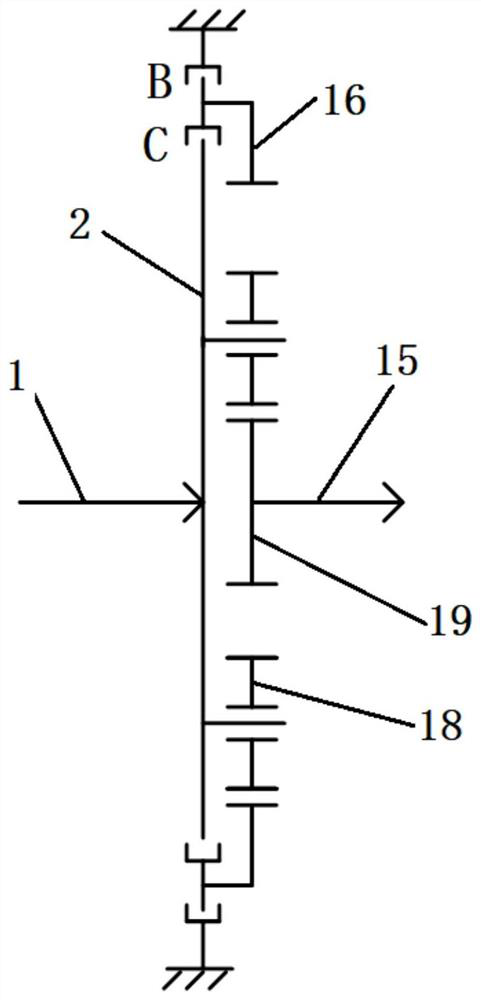

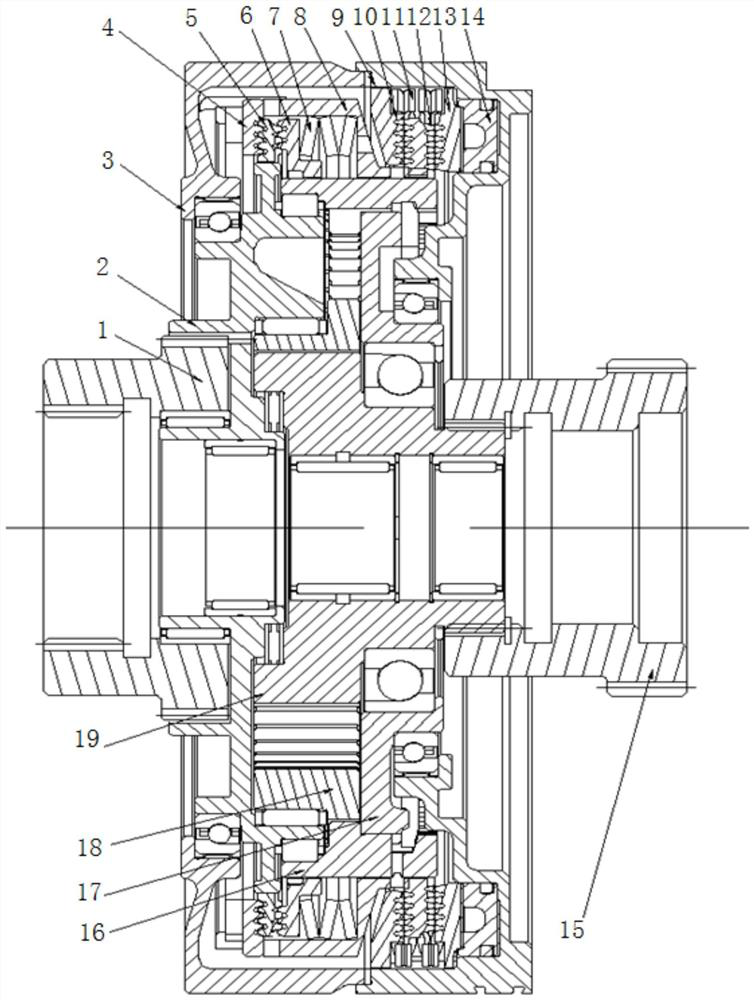

[0020] This embodiment provides a double internal meshing positive and negative mechanism, including: input shaft 1, output shaft 15, double internal meshing planetary row, clutch C, brake B; wherein the double internal meshing planetary row includes: planetary carrier 2, ring gear 16 , the sun gear 19 and the planetary gear 18 with internal and external teeth.

[0021] The transmission principle of the double internal meshing positive and negative mechanism is as follows: figure 1 As shown, the outer teeth of the planetary gear 18 mesh with the ring gear 16, and the inner teeth mesh with the sun gear 19, and the planet carrier 2 is used to support the planetary gear 18. The input shaft 1 is connected with the planet carrier 2, and the output shaft 15 is connected with the sun gear 19; the clutch and the brake are linked, that is, when the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com