Lubrication point terminal detection device and lubrication system

A detection device and lubrication system technology, applied in distribution devices, lubricating parts, lubricating oil control valves, etc., can solve the problems of low oil pressure and cannot be detected, and achieve the effects of simple structure, high reliability and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

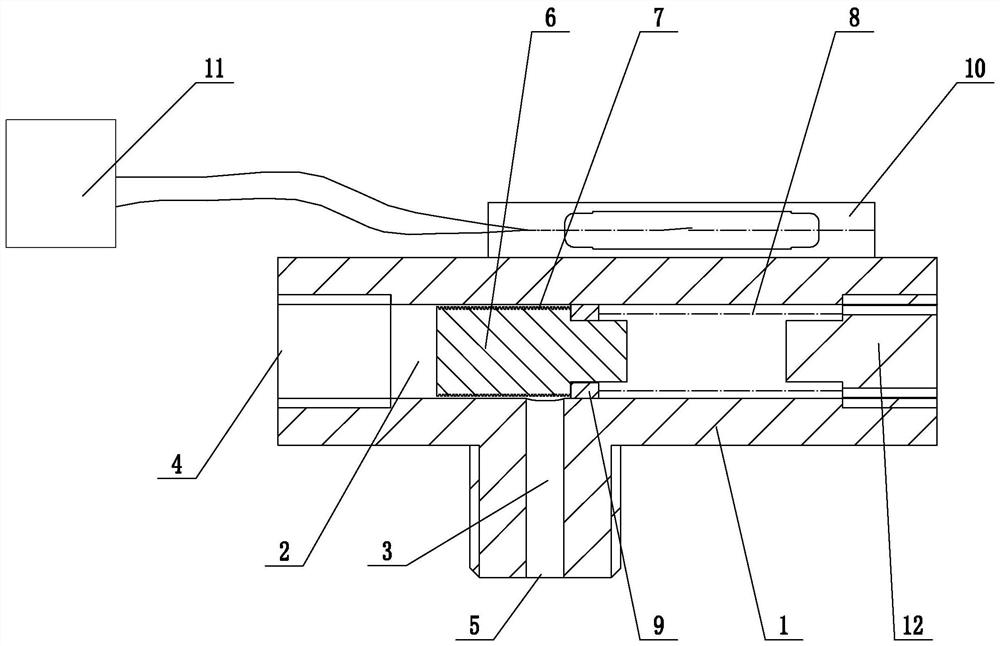

[0023] Embodiment 1: A device for detecting the terminal of a lubrication point (see attached figure 1 ), including the device main body 1 connected to the lubricating point terminal, the device main body is provided with an oil inlet hole 2 and an oil outlet hole 3, one end of the oil outlet hole penetrates to the outer wall of the device main body to form an oil outlet 5, and the other end of the oil outlet hole is connected to the inlet The oil hole is connected, and an axially movable moving part 6 is installed in the corresponding position of the oil inlet hole and the oil outlet hole. The outer wall of the moving part is provided with a spiral oil delivery groove 7, and one end of the oil inlet hole penetrates to the outer wall of the main body of the device to form an oil inlet 4 , an elastic return member 8 is installed between the other end of the oil inlet hole and the moving part, the elastic return member is a return spring, an induction block 9 is installed on the ...

Embodiment 2

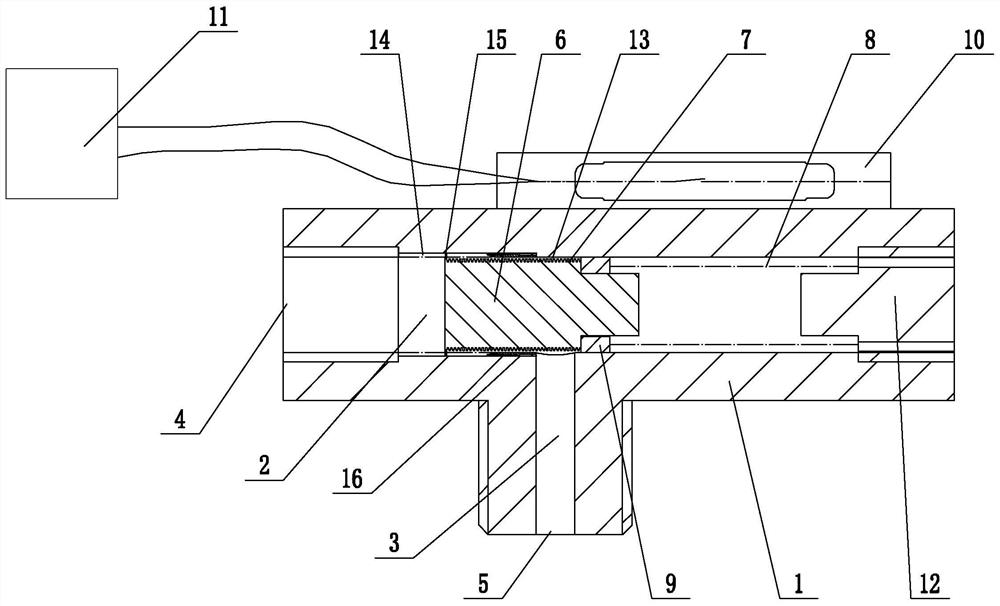

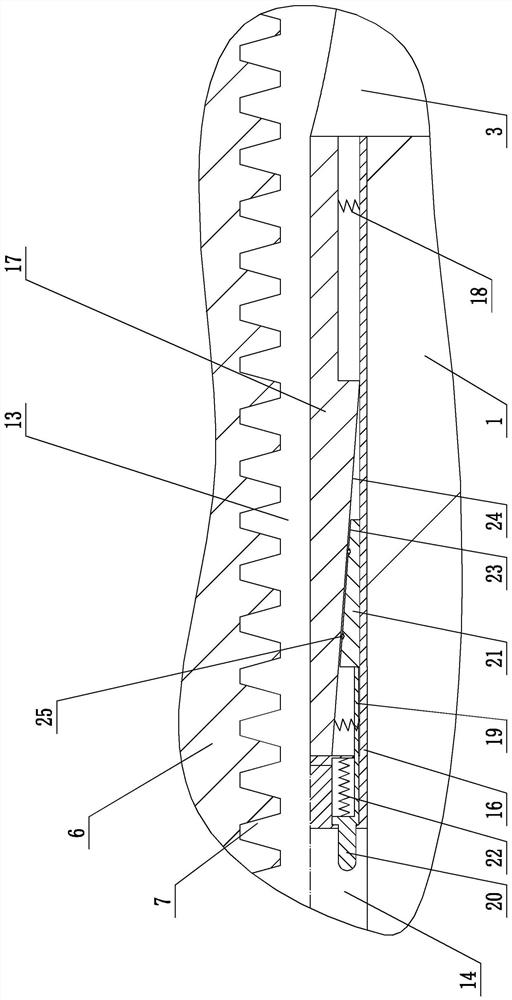

[0026] Embodiment 2: A device for detecting the terminal of a lubrication point (see attached figure 2 , attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, there is an oil gap 13 between the outer wall of the moving part and the inner wall of the oil inlet hole, and a number of axially arranged installation grooves are arranged on the inner wall of the oil inlet hole 14. The installation groove extends from the oil inlet to the oil outlet. The end position of the moving part facing the oil inlet and the installation groove are provided with a number of sliding posts 15 one by one. The sliding posts are fitted in the installation groove. A strip-shaped mounting seat 16 is installed in the mounting groove near the end of the oil outlet, and an inserting strip 17 that can move radially toward the moving parts is installed in the mounting seat, and a tension spring 18 is connected between the inserting strip and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com