Large-size display defect detection and positioning method

A defect detection and positioning method technology, applied in the field of display screen, can solve the problems of complicated positioning process, increased AOI station detection time, low robustness, etc., to save detection time, quality inspection efficiency and product quality control improvement , improve the accuracy and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

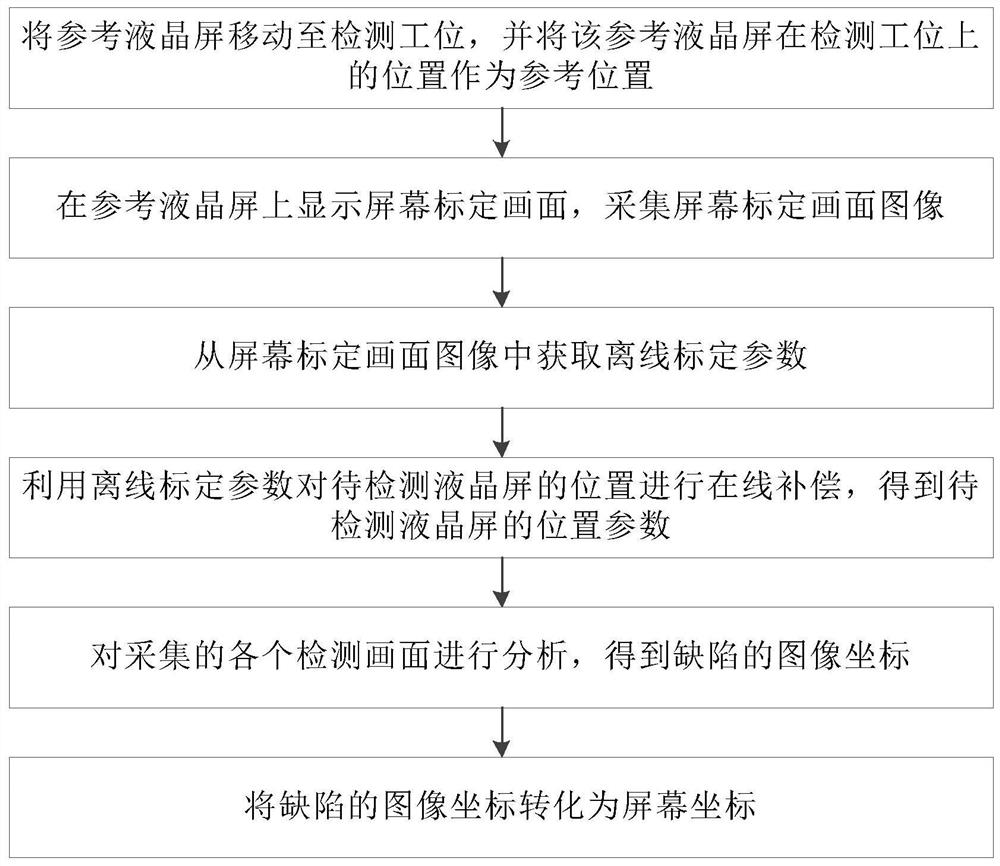

[0047] Such as figure 1 The flow chart of a large-size display defect detection and positioning method is shown, and this embodiment uses a liquid crystal screen for illustration:

[0048] 1. Multi-vision sensor offline calibration.

[0049] A liquid crystal screen is used as a reference liquid crystal screen (usually the first detected liquid crystal screen is selected as a reference liquid crystal screen) and moved to the detection station, and the position of the reference liquid crystal screen on the detection station is used as a reference position.

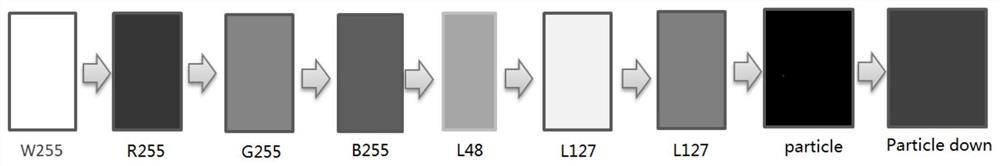

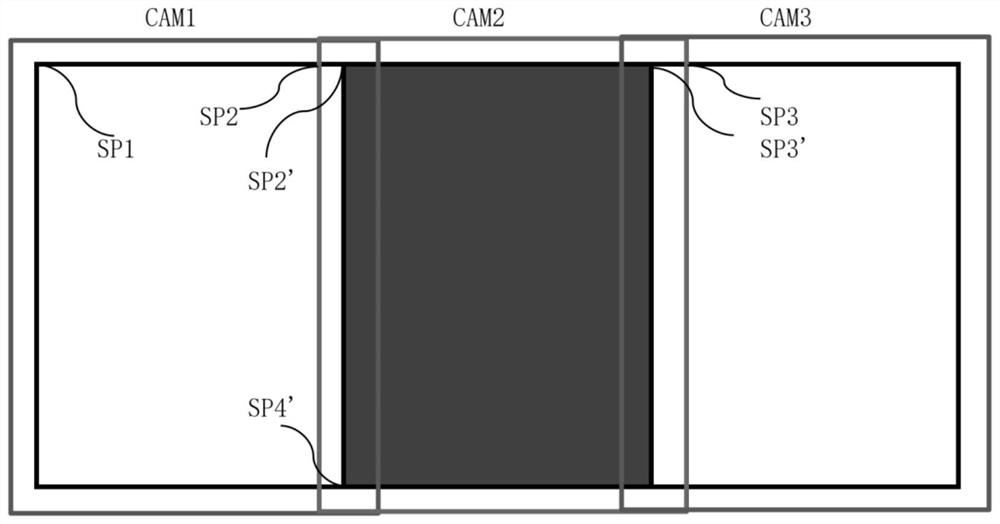

[0050] The screen calibration picture is displayed on the reference liquid crystal screen, and the images of the screen calibration picture are collected by using a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com