Reflective black reflective film and production process thereof

A production process and technology of reflective film, applied in the field of reflective film, can solve the problems of restricting the application of reflective film and low reflective coefficient, achieve good reflective effect, good reflective performance, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

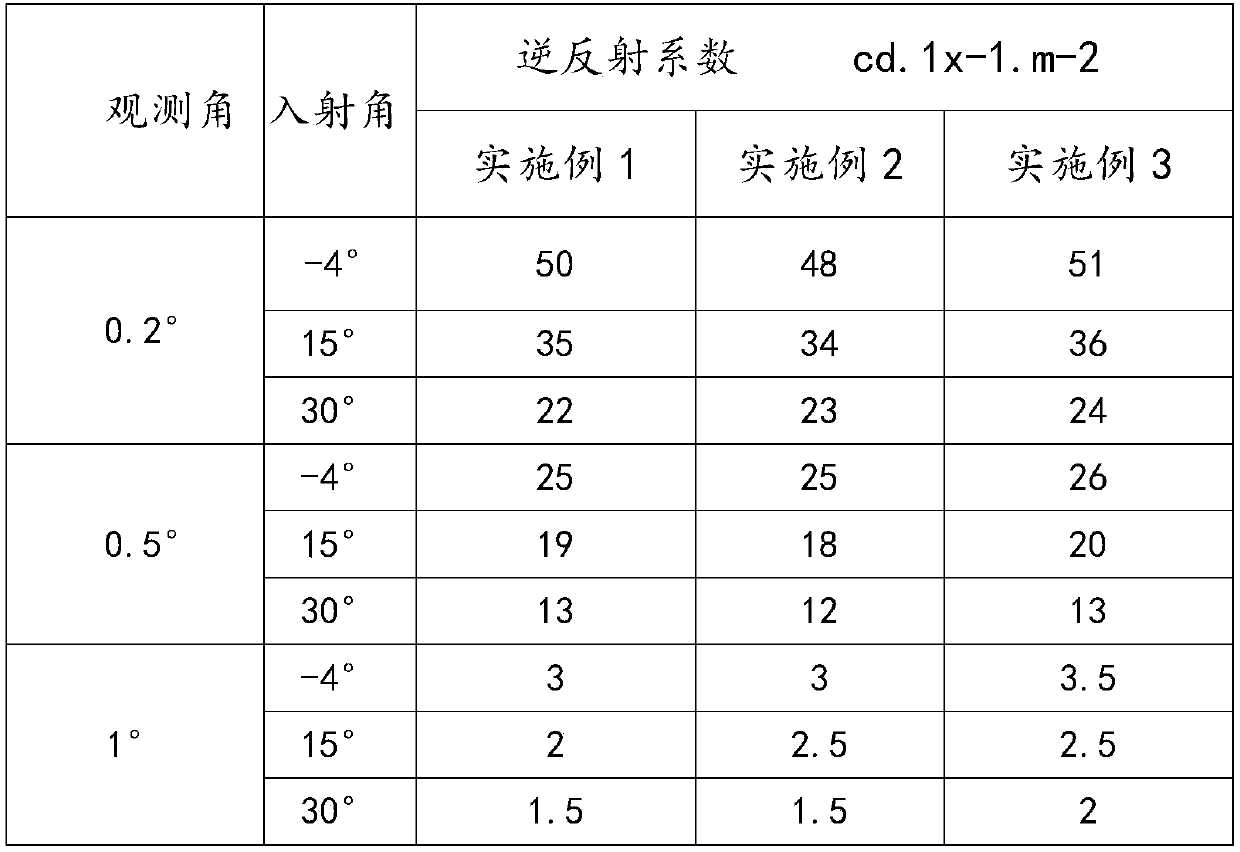

Embodiment 1

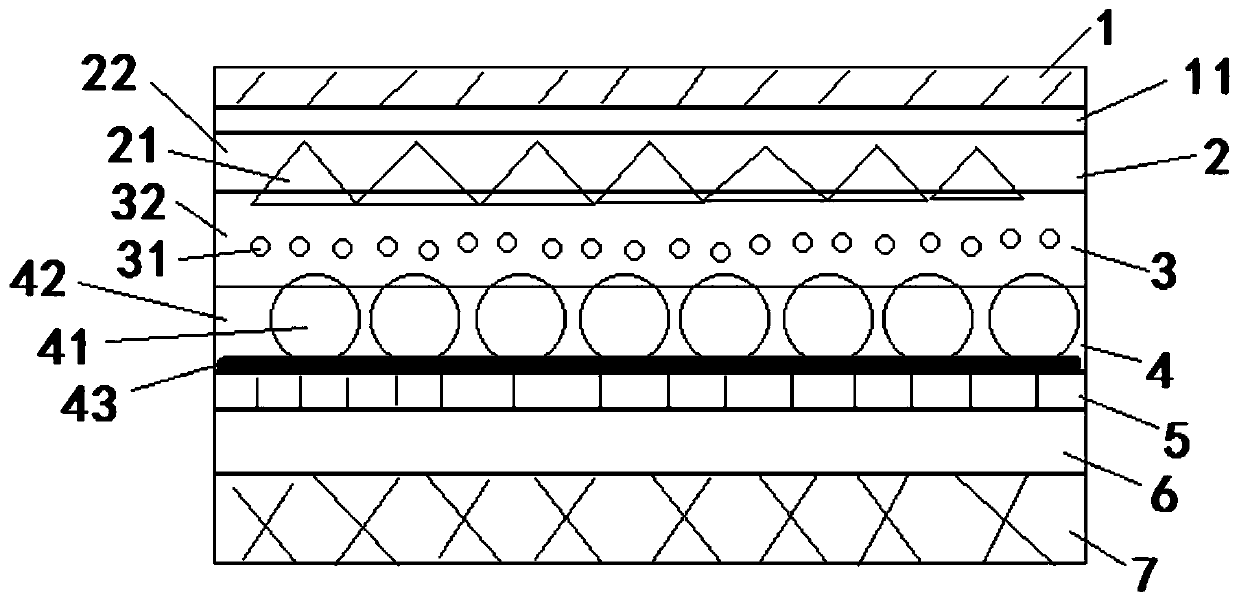

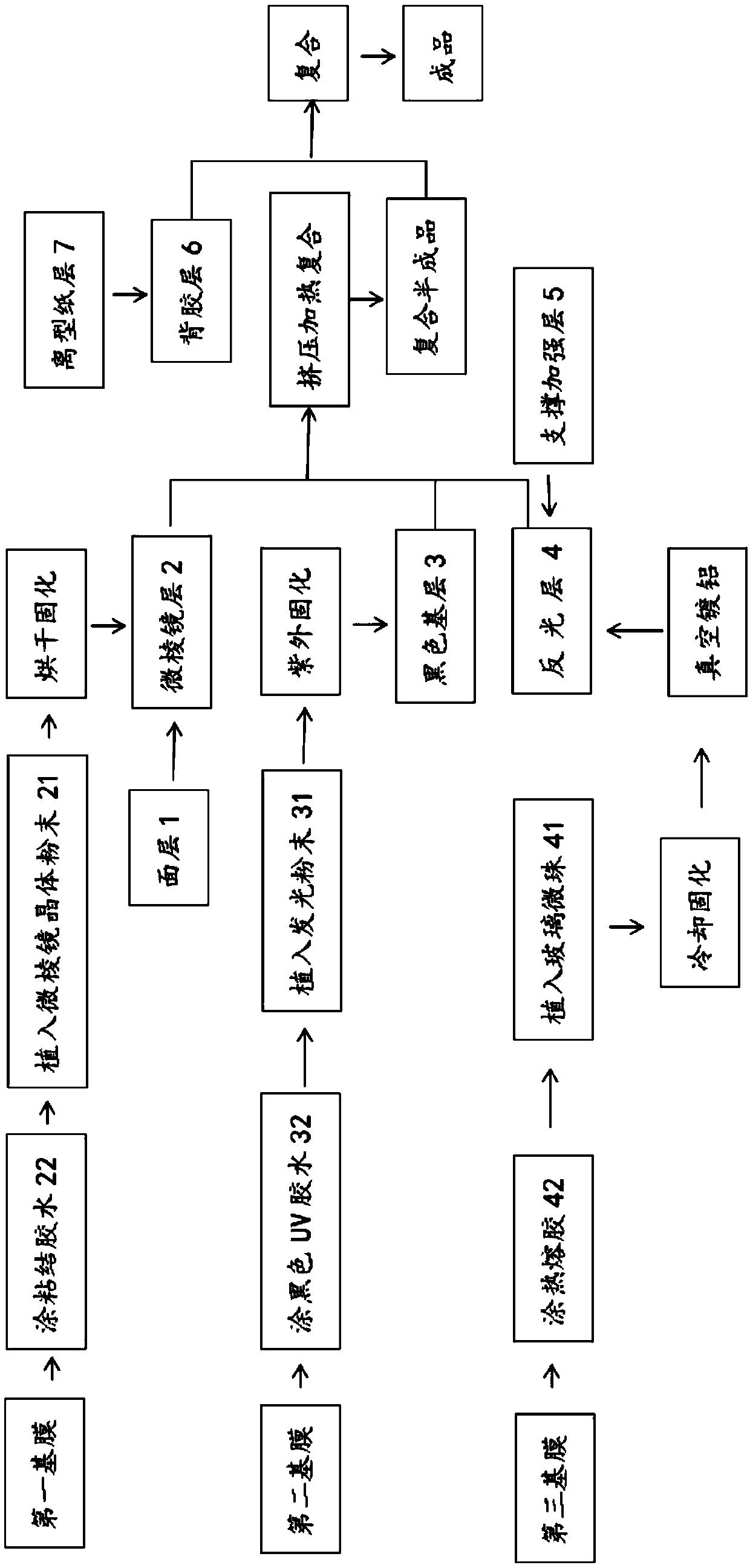

[0028] Such as figure 1 As shown, a reflective black reflective film, from top to bottom, sequentially includes a surface layer 1, a microprism layer 2, a black base layer 3, a reflective layer 4, a support reinforcement layer 5, an adhesive layer 6, and a release paper layer 7 , microprism crystal powder 21 is closely arranged in the microprism layer 2, luminous powder 31 is evenly distributed in the black base layer 3, the reflective layer 4 includes glass microspheres 41 and an aluminum coating layer 43, and the supporting reinforcement layer 5 is a hard acrylic resin layer The surface layer 1 is made of acrylic material, the microprism crystal powder 21 is an equilateral triangular prism crystal powder, the luminescent powder 31 is a transparent phosphor powder, the fineness of the luminescent powder is 200 mesh, and the particle size of the glass beads 41 is 10 μm. The refractive index is 1.92, and the adhesive layer 6 is a pressure-sensitive adhesive layer.

[0029] Suc...

Embodiment 2

[0038] Such as figure 1 As shown, a reflective black reflective film, from top to bottom, sequentially includes a surface layer 1, a microprism layer 2, a black base layer 3, a reflective layer 4, a support reinforcement layer 5, an adhesive layer 6, and a release paper layer 7 , microprism crystal powder 21 is closely arranged in the microprism layer 2, luminous powder 31 is evenly distributed in the black base layer 3, the reflective layer 4 includes glass microspheres 41 and an aluminum coating layer 43, and the supporting reinforcement layer 5 is a hard acrylic resin layer , the surface layer 1 is made of acrylic material, the microprism crystal powder 21 is an equilateral triangular prism crystal powder, the luminescent powder 31 is a transparent phosphor powder, the fineness of the luminescent powder is 250 mesh, and the particle size of the glass beads 41 is 80 μm. The refractive index is 1.93, and the adhesive layer 6 is a pressure-sensitive adhesive layer.

[0039] S...

Embodiment 3

[0048]Such as figure 1 As shown, a reflective black reflective film, from top to bottom, sequentially includes a surface layer 1, a microprism layer 2, a black base layer 3, a reflective layer 4, a support reinforcement layer 5, an adhesive layer 6, and a release paper layer 7 , microprism crystal powder 21 is closely arranged in the microprism layer 2, luminous powder 31 is evenly distributed in the black base layer 3, the reflective layer 4 includes glass microspheres 41 and an aluminum coating layer 43, and the supporting reinforcement layer 5 is a hard acrylic resin layer , the surface layer 1 is made of acrylic material, the microprism crystal powder 21 is an equilateral triangular prism crystal powder, the luminescent powder 31 is a transparent phosphor powder, the fineness of the luminescent powder is 300 mesh, and the particle size of the glass beads 41 is 120 μm. The refractive index is 1.94, and the adhesive layer 6 is a pressure-sensitive adhesive layer.

[0049] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap