OLED display panel and preparation method thereof

A display panel and display area technology, applied in semiconductor/solid-state device manufacturing, electrical components, diodes, etc., can solve problems such as high reflection and achieve the effect of improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

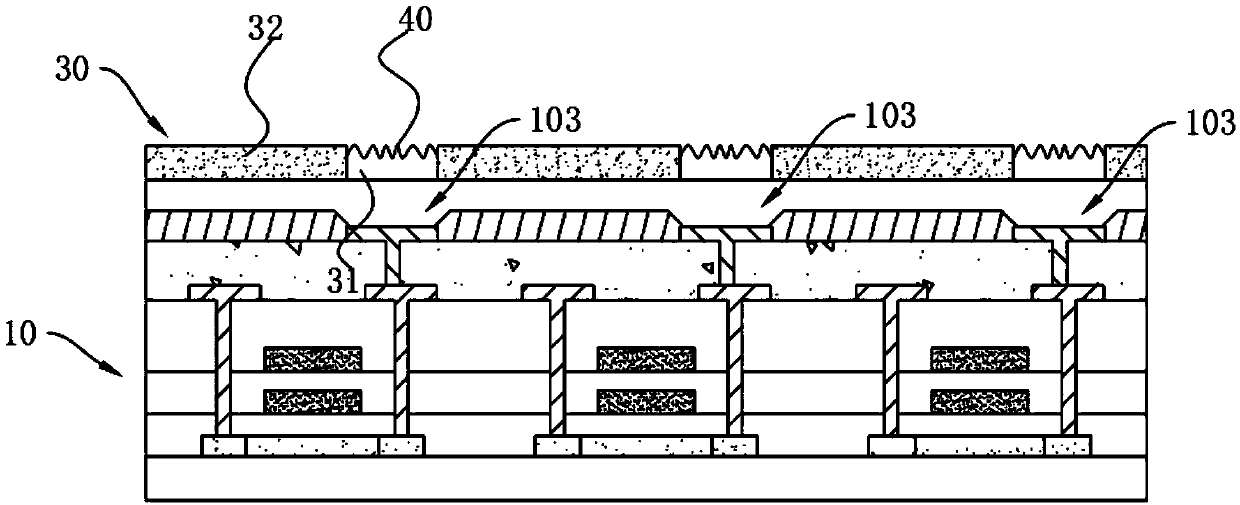

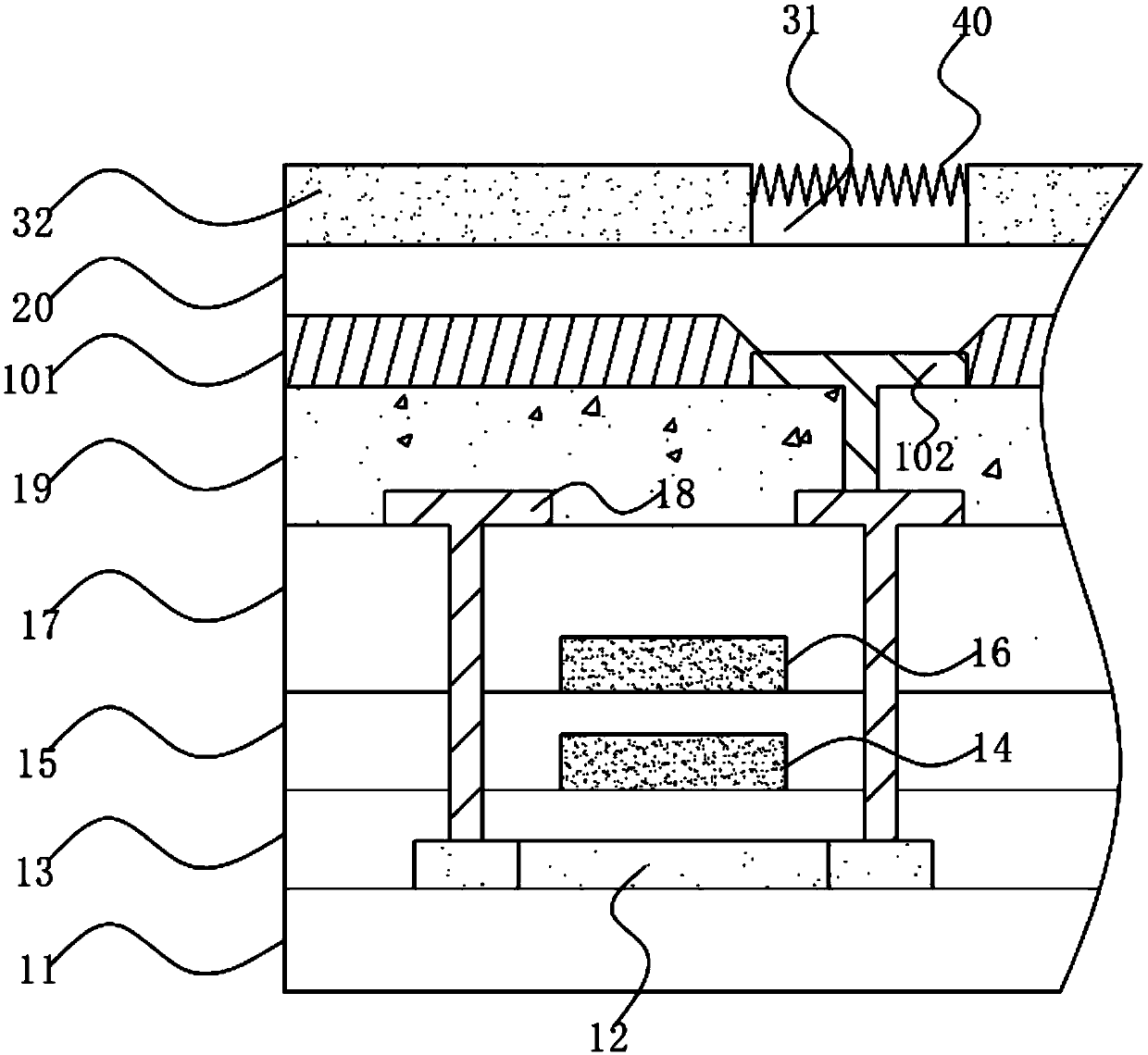

[0042] A kind of OLED display panel, such as figure 1 with figure 2 , the OLED display panel includes a display device board 10 , an encapsulation layer 20 disposed on the display device board 10 , and a color filter substrate 30 disposed on the encapsulation layer 20 .

[0043] Wherein, the display device panel 10 includes a display area 103 , the color filter substrate 30 includes a light-transmitting area 31 and a light-shielding area 32 formed by a black matrix, and the light-transmitting area 31 corresponds to the display area 103 .

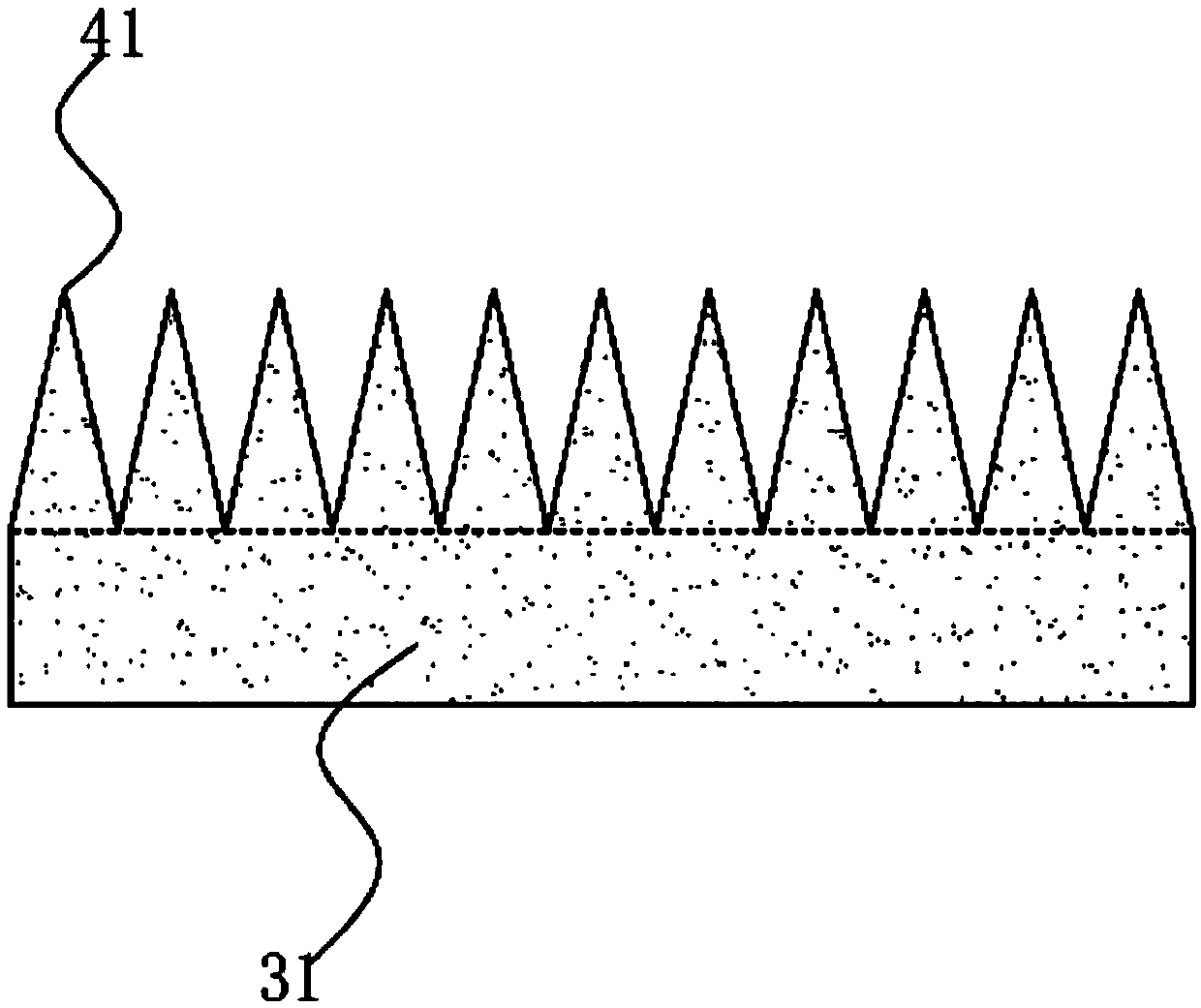

[0044] Wherein, the light-transmitting region 31 on the color filter substrate 30 is provided with a scattering structure 40 for scattering ambient light, and the scattering structure 40 includes a plurality of bumps 41, and the width of the bumps 41 is less than 600 nanometers .

[0045] By setting the scattering structure 40 at the light-transmitting region 31 of the color filter substrate 30, those skilled in the art know that when the...

Embodiment 2

[0057] A kind of OLED display panel, such as Figure 7 As shown, the only difference between it and the first embodiment lies in the shape of the scattering structure 40 .

[0058] Specifically, the shape of the longitudinal section of the bumps 41 is rectangular, the gaps 42 between the bumps are arranged, and the total area of all the gaps 42 between the bumps 41 is 1 / 2 of the total area of the light-transmitting region 31 0.2 to 0.5 times.

[0059] By making the gap 42 in the scattering structure 40 have an appropriate duty ratio, the anti-reflection effect of the scattering structure 40 on transmitted light is further improved, while the reflection effect on ambient light is reduced, and the contrast of the OLED display panel is improved.

[0060] It should be noted that, see Figure 8 to Figure 10 , Figure 8 to Figure 10 It is an experimental simulation diagram of the light transmittance of the color filter substrate 30 to light of different wavelengths when the g...

Embodiment 3

[0063] A kind of OLED display panel, such as Figure 11 As shown, the only difference between it and the first embodiment lies in the shape of the scattering structure 40 .

[0064] Specifically, the longitudinal section of the bumps 41 is trapezoidal.

[0065] It should be noted that the longitudinal section of the bumps 41 may be a straight trapezoid or an inverted trapezoid; the bumps 41 may be arranged in gaps or continuously.

[0066] It should be noted that, see Figure 12 to Figure 14 , Figure 12 to Figure 14 It is an experimental simulation diagram of the light transmittance of the color filter substrate 30 to light of different wavelengths when the longitudinal sections of the bumps 41 have different shapes.

[0067] Figure 12 is the simulation schematic diagram when there is no scattering structure; Figure 13 It is a simulation schematic diagram when the longitudinal section of the bump 41 is a positive trapezoid; Figure 14 It is a simulation schematic diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com