The Realization Method of Vector Control of Three-phase Asynchronous Motor

A vector control and three-phase asynchronous technology, which is applied in the field of vector control of three-phase asynchronous motors, can solve the problem that the rotor flux model is unreasonable, the physical connection of variables under the two-axis cannot be fully utilized, and the theoretical effect of vector control technology is difficult to obtain and other problems, to achieve the effect of avoiding overload and overheating operation, avoiding high-frequency noise amplification, and large output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Below in conjunction with accompanying drawing and embodiment, the utility model is described in detail:

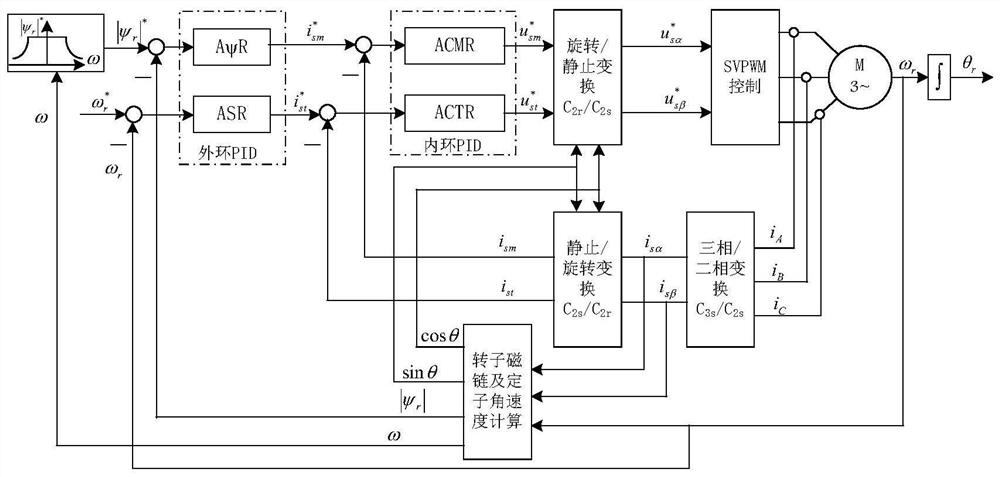

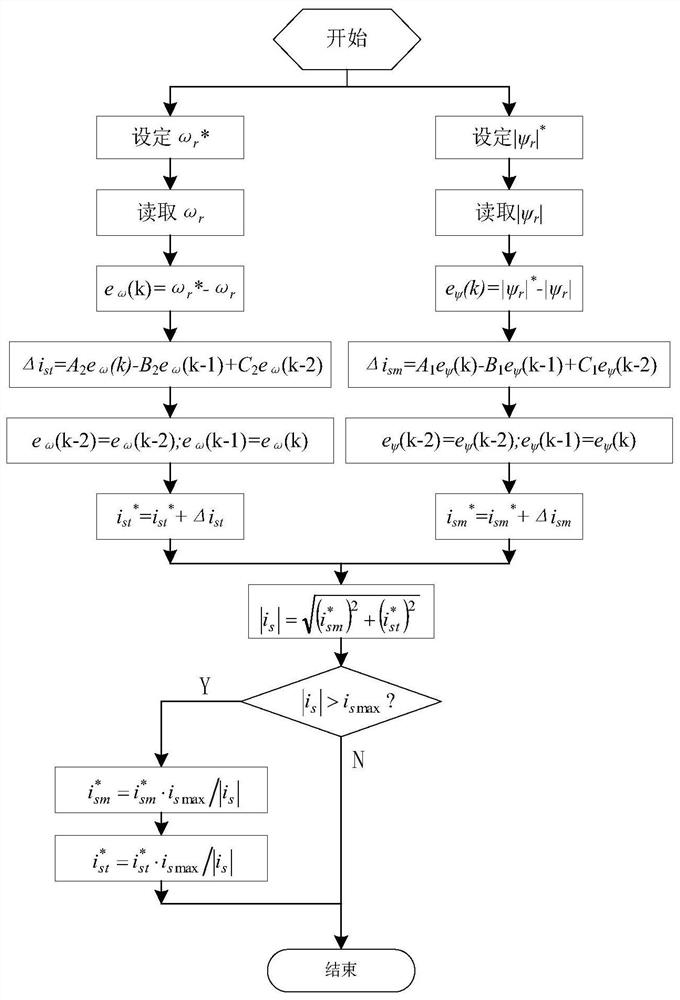

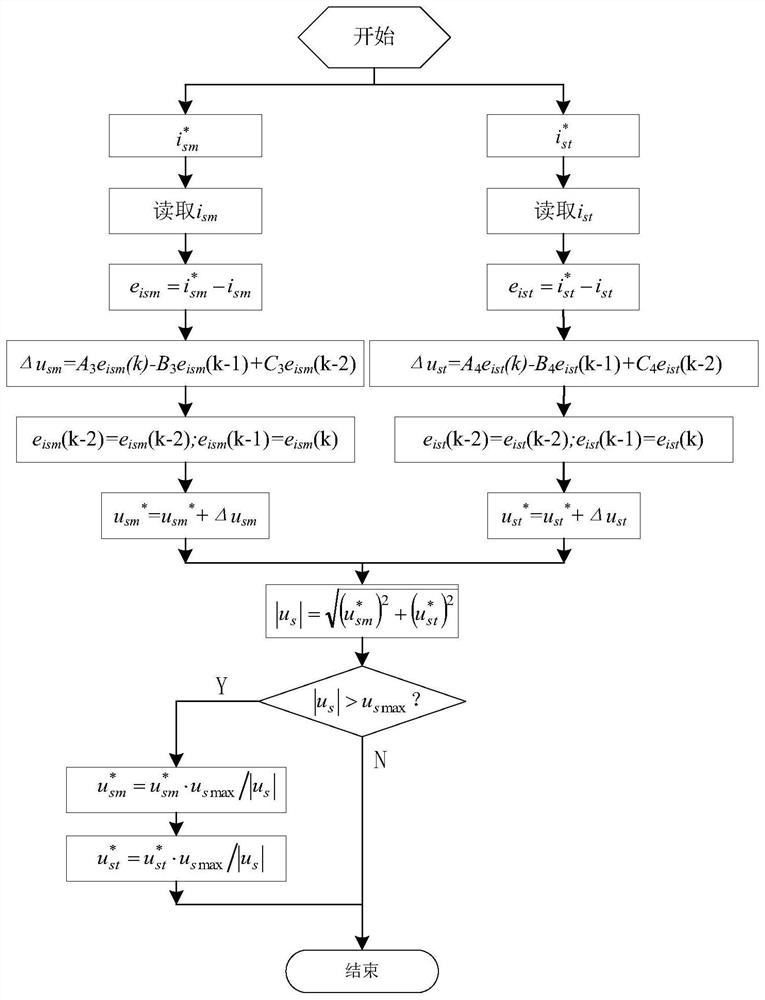

[0112] The realization method of three-phase asynchronous motor vector control, the steps are as follows:

[0113] 1. Mathematical model of three-phase asynchronous motor

[0114] In the rotating coordinate system, with The state equation of the three-phase squirrel-cage asynchronous motor with state variables:

[0115]

[0116] In the formula, i sd , i sq is the components of the d-axis and q-axis of the stator current space vector in the rotating dq coordinate system; u sd , u sq is the component of the d-axis and q-axis of the electron voltage space vector in the rotating dq coordinate system; ψ rd , ψ rq is the component of the stator flux linkage vector in the rotating dq coordinate system of the d-axis and the q-axis; J is the moment of inertia; B is the viscous friction coefficient; T l is the load torque; p is the differential operator; σ is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com